In today's rapidly evolving manufacturing landscape, injection molding projects are at the forefront of innovative advancements slated to reshape the industry. As businesses strive to optimize production efficiency and reduce costs, the adoption of cutting-edge technologies such as automation, artificial intelligence, and sustainable materials has become paramount. According to a recent report by MarketsandMarkets, the global injection molding market is projected to reach $345 billion by 2025, highlighting the robust growth and significance of this manufacturing process in various sectors including automotive, consumer goods, and medical devices.

Industry expert Dr. Emily Reece emphasizes the importance of staying ahead in this competitive market, stating, "The future of injection molding projects lies not only in adopting new technologies but in leveraging data-driven insights to enhance every stage of the production lifecycle." Her insights underline the critical need for manufacturers to embrace digital transformation and innovative methodologies to meet the complex demands of modern consumers. As we delve into the latest trends shaping injection molding projects, it is vital to consider how these advancements can lead to not just better products but a more sustainable future for the industry.

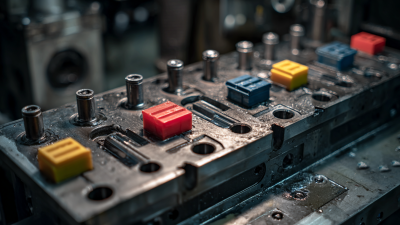

The injection molding industry is undergoing a significant transformation driven by emerging technologies that are reshaping processes and enhancing efficiency. One notable trend is the integration of advanced automation and robotics. These technologies not only streamline operations but also minimize human error and reduce labor costs. By employing collaborative robots, manufacturers can achieve a higher precision level in molding processes, allowing for more complex and intricate designs that cater to the demands of modern consumers.

Another revolutionizing technology is the rise of 3D printing in conjunction with injection molding. This hybrid approach allows for rapid prototyping and customization of molds, significantly shortening production cycles and decreasing costs. Moreover, advancements in materials science have led to the development of new polymer blends that are more sustainable and perform better than traditional options. These innovative materials enable companies to create lighter, stronger, and more environmentally friendly products, positioning them favorably in a competitive market. As these technologies continue to evolve, they promise to unlock new possibilities, making injection molding more efficient and responsive to industry needs.

Sustainable practices are rapidly transforming the injection molding industry, as companies prioritize eco-friendly initiatives alongside operational efficiency. According to a report by Grand View Research, the global injection molding market is projected to reach $392.06 billion by 2028, with sustainability driving a significant portion of this growth. Factors such as the increased use of recycled materials and the development of bioplastics are becoming pivotal. In particular, bioplastics, which are derived from renewable biomass sources, are gaining traction in injection molding applications, making the process more environmentally friendly while meeting consumer demand for sustainable products.

One effective way to implement sustainable practices in injection molding is by optimizing energy usage. Manufacturers can adopt energy-efficient machinery and implement smart factory technologies to monitor and reduce energy consumption. Additionally, using recycled materials not only decreases waste but also lowers production costs. According to a report from the Plastics Industry Association, 91% of plastics are recyclable, and incorporating recycled content into new products can lower emissions by 30%.

Tip: Consider collaborating with suppliers who prioritize sustainability. Establishing partnerships with those who focus on eco-friendly materials can streamline the injection molding process and enhance your brand's reputation among environmentally conscious consumers.

| Trend | Description | Sustainability Impact | Technology Involved | Future Prospects |

|---|---|---|---|---|

| Bio-based Materials | Utilization of renewable resources for plastic production. | Reduces carbon footprint and reliance on fossil fuels. | Biotechnology, Material Science | Growing market demand and innovation in bio-plastics. |

| Recycling and Reuse | Implementing closed-loop systems for material recycling. | Lowers waste production and conserves resources. | Recycling Technologies, Mechanical Engineering | Increased regulatory support and consumer preference for sustainability. |

| Smart Manufacturing | Integration of IoT and AI in manufacturing processes. | Enhances efficiency and minimizes resource waste. | Artificial Intelligence, IoT, Machine Learning | Promising advancements in automation and process optimization. |

| Energy-efficient Machines | Machines designed to consume less energy during operation. | Reduces operational costs and environmental impact. | Mechanical Engineering, Energy Management | Expected to become standard in manufacturing facilities. |

| Additive Manufacturing | Combination of traditional molding techniques with 3D printing. | Reduces waste and allows for complex designs with less material. | 3D Printing, CAD Technology | Increased application in custom and small-batch production. |

The landscape of injection molding design is rapidly evolving, driven by trends in customization and personalization. As consumers increasingly seek unique products tailored to their preferences, manufacturers are embracing innovative approaches to meet this demand. The global market for personalized goods has surged, highlighted by notable growth in sectors like 3D PVC rubber patches and custom printing. This shift emphasizes the need for injection molding projects to focus on delivering customized solutions that resonate with individual consumer identities.

In light of these trends, manufacturers are exploring advanced technologies such as generative AI, which can significantly enhance product design and production processes. By leveraging AI capabilities, companies can create unique mold designs that cater to specific customer needs and preferences. Additionally, the integration of in-mold labeling reflects a commitment to personalizing products on a deeper level, adding a bespoke touch in the manufacturing process. As the injection molding industry adapts to these innovative trends, the emphasis on customization and personalization will undoubtedly shape its future trajectory.

The integration of automation and artificial intelligence (AI) into modern injection molding processes marks a transformative shift in the manufacturing landscape. Automation allows for the streamlining of production lines, reducing human error and enhancing efficiency through precision control. Intelligent machines can monitor operational parameters in real time and adjust settings to optimize the molding process, ensuring consistent quality and significant cost savings.

Moreover, AI plays a crucial role in predictive maintenance and quality assurance. By analyzing production data, AI systems can foresee potential equipment failures before they occur, significantly minimizing downtime. Additionally, machine learning algorithms can evaluate product defects during production, allowing for immediate corrections. This level of responsiveness not only improves product reliability but also elevates overall productivity, positioning companies to meet the increasingly complex demands of the market.

As these technologies continue to evolve, they will unlock new possibilities for innovation and growth within the injection molding industry.

Innovative materials are reshaping the landscape of injection molding applications. As industries strive for greater efficiency and sustainability, the use of advanced polymers and bioplastics has surged. These materials not only enhance the performance and durability of molded products but also reduce environmental impact. For instance, thermoplastic elastomers (TPEs) offer flexibility and resilience, making them ideal for applications ranging from automotive components to consumer goods.

Tips: When selecting materials for injection molding projects, consider the specific requirements of your application, such as temperature resistance and mechanical properties. Collaborating with suppliers who specialize in innovative materials can lead to new opportunities and improved product design.

Furthermore, the introduction of recycled materials into the injection molding process is gaining traction. By integrating recycled plastics, manufacturers can create products that are both cost-effective and environmentally friendly. This trend not only supports sustainable practices but also helps companies meet regulatory standards and consumer demands for greener products.

Tips: Explore partnerships with recycling companies to source high-quality recycled materials. Additionally, invest in technology that enables the efficient processing of these materials to ensure that quality is not compromised.