In the rapidly evolving landscape of manufacturing, understanding the nuances of molding pressure has become a pivotal factor for achieving optimal production outcomes. As noted by industry expert Dr. Elizabeth Harmon, "The careful management of molding pressure can significantly enhance product quality and reduce cost in the manufacturing process." With an eye toward 2025, manufacturers are increasingly focusing on refining their techniques to harness the full potential of molding pressure, ensuring both efficiency and precision.

Molding pressure plays a crucial role in determining the final properties of molded parts, making it essential for engineers and manufacturers alike to delve into its intricacies. This guide aims to illuminate the crucial aspects of molding pressure, offering insights into best practices and innovative techniques that can redefine manufacturing standards. By embracing these strategies, businesses can not only improve their operational efficiency but also enhance product performance in a competitive market.

As we explore the realm of molding pressure in this comprehensive guide, we will uncover various methodologies that can be employed to optimize pressure settings, leading to sustainability and cost-effectiveness in production. Understanding molding pressure is not just about technical knowledge—it's about embracing a holistic approach to manufacturing that prioritizes quality and adaptability in an ever-changing industry.

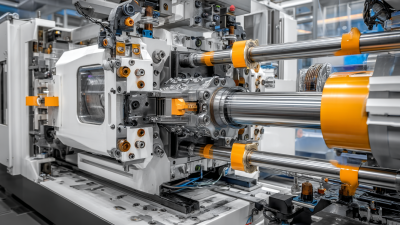

Molding pressure plays a crucial role in the manufacturing processes of various industries, impacting product quality and production efficiency. According to a report by the Society of Plastics Engineers, the optimal molding pressure can significantly influence the mechanical properties of the final product, such as strength and durability. Studies indicate that a precise adjustment of molding pressure can lead to a reduction in defects by up to 30%, thereby minimizing waste and enhancing overall production yield.

Tips: To optimize molding pressure, manufacturers should consider conducting routine calibration of their injection molding machines. Regular monitoring tools can help ensure that pressure levels are maintained accurately, thus facilitating consistent product quality.

Additionally, integrating advanced simulation software can provide valuable insights into the relationship between molding pressure and polymer flow behavior. This approach allows for the fine-tuning of parameters even before physical production begins. By implementing these strategies, manufacturers can leverage the importance of molding pressure for better outcomes in product development.

Achieving optimal molding pressure is crucial for efficiency and product quality in manufacturing processes. Several key factors influence the selection of ideal molding pressure settings, including material characteristics, mold design, and processing conditions. According to the 2023 Plastics Industry Trends Report, nearly 40% of manufacturers reported that improper pressure settings led to increased scrap rates and production downtime. Understanding the behavior of different materials under pressure can significantly streamline production processes and improve final product integrity.

One pivotal element is the viscosity of the polymer being used. High-viscosity materials often require elevated pressures to ensure proper flow, whereas low-viscosity polymers can be successfully molded at lower pressures. Additionally, the design of the mold itself plays a critical role; factors like cavity geometry and venting can impact how pressure is distributed during the injection process. A recent study by the Society of Plastics Engineers highlighted that optimizing mold design could lead to a 20% increase in overall process efficiency.

**Tips:** When setting your molding pressure, always test with different materials to find the sweet spot that minimizes defects. Monitor your machine’s pressure settings consistently, as fluctuations can lead to variations in product quality. Remember to involve your team in reviewing the data post-production to ensure that everyone understands the impact of pressure settings on overall output.

| Molding Material | Optimal Pressure (psi) | Temperature (°C) | Cycle Time (min) |

|---|---|---|---|

| Polypropylene | 400 | 200 | 5 |

| Polycarbonate | 500 | 220 | 6 |

| Nylon | 450 | 210 | 5.5 |

| Acrylonitrile Butadiene Styrene (ABS) | 480 | 230 | 5 |

| Polyethylene | 390 | 180 | 4.5 |

Accurately measuring molding pressure is crucial for optimizing manufacturing processes in the molding industry. According to a recent report by the Plastics Industry Association, about 75% of defects in molded products are attributed to inadequate pressure control. Utilizing advanced pressure sensors and data acquisition systems allows manufacturers to maintain consistent pressure throughout the molding cycle, which is essential for achieving high-quality end products.

Techniques such as in-mold pressure measurement provide real-time data, enabling operators to make immediate adjustments. Specifically, piezoelectric sensors have emerged as a preferred choice for their high sensitivity and rapid response times, which are essential for quality assurance. A study from the Journal of Manufacturing Processes highlighted that implementing these technologies can reduce production fallout by up to 30%, significantly improving overall efficiency and profitability. By focusing on precise molding pressure measurement techniques, manufacturers can not only enhance product quality but also minimize material waste and operational costs.

Managing molding pressure effectively is crucial for achieving high-quality manufacturing results. One of the most common mistakes manufacturers make is not properly calibrating their machines to the specific material being used. Each material has its own ideal pressure range, and failure to adjust the pressure accordingly can lead to defects such as warping, incomplete filling, or excessive flash. Regular training sessions for operators can help ensure they fully understand how to set and adjust pressure based on material specifications.

Another frequent issue arises from overlooking the role of cooling systems in conjunction with molding pressure. Inadequate cooling can cause parts to experience uneven shrinkage, which not only affects the final dimensions but can also lead to stress points that compromise the integrity of the product. Implementing a proactive maintenance schedule for cooling systems can help mitigate these problems, ensuring that the cooling process works harmoniously with the molding pressure to produce consistent, defect-free products.

As industries evolve, the optimization of molding pressure remains a pivotal concern for manufacturers aiming to enhance production efficiency. According to a report by MarketsandMarkets, the global injection molding market is projected to reach $367.4 billion by 2025, highlighting the critical nature of managing molding parameters in meeting growing production demands. Advanced molding techniques are increasingly incorporating real-time data analytics and automated systems to adjust molding pressure dynamically, ensuring consistency and quality in final products.

Moreover, recent studies indicate that properly calibrated molding pressure can reduce material waste by up to 30%, significantly cutting costs and increasing sustainability efforts. Innovations such as gas-assist molding and multi-material molding are set to redefine best practices, allowing for finer control over pressure profiles throughout the manufacturing process. As manufacturers invest in smarter technologies and predictive maintenance models, the ability to optimize molding pressure will become essential for competitive advantage, driving both efficiency and product quality.