In the dynamic landscape of manufacturing, Injection Molding stands out as a pivotal technique, accounting for approximately 30% of all plastic production globally. This process not only enables the efficient creation of complex shapes but also provides significant cost efficiency, making it the go-to method for industries ranging from automotive to consumer goods. According to a recent report by a leading market research firm, the global injection molding market is projected to reach USD 400 billion by 2026, driven by innovations in materials and technologies. As businesses vie for a competitive edge, understanding the best strategies for achieving excellence in Injection Molding becomes crucial. This blog delves into top insights and innovations that enhance production standards, improve quality, and optimize cost-effectiveness in this essential manufacturing process.

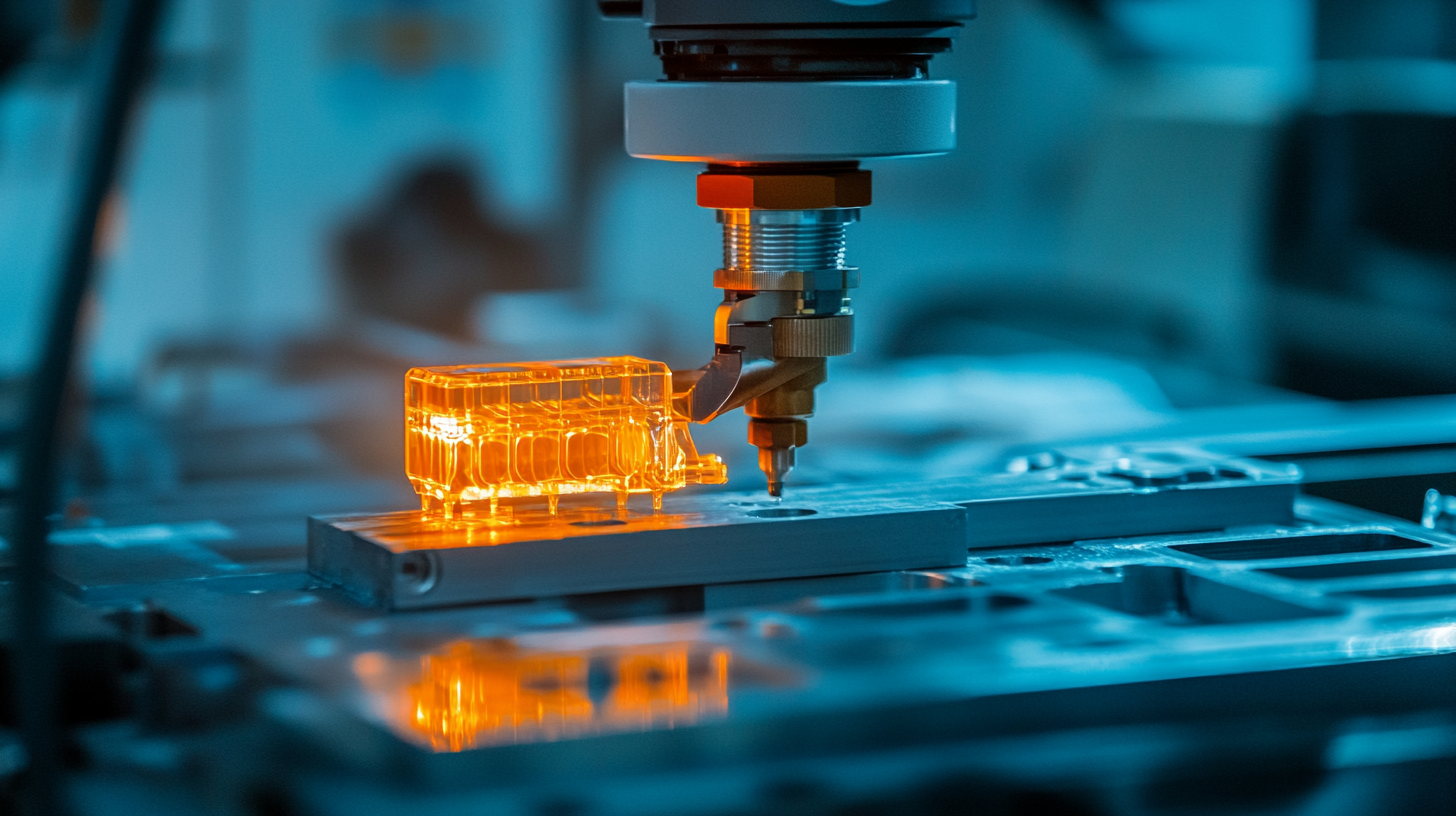

When seeking excellence in injection molding, identifying key qualities in top-notch suppliers is paramount. According to a report by MarketsandMarkets, the global injection molding market is projected to reach $344.79 billion by 2026, highlighting the growing demand for high-quality services. Suppliers must demonstrate a strong commitment to innovation, utilizing advanced technologies such as 3D printing and automation to streamline production processes and enhance product quality.

One of the essential qualities to look for is a supplier’s ability to provide customized solutions. As outlined in a study by Grand View Research, customization is increasingly becoming a priority for manufacturers seeking competitive advantages. A great supplier should have a proven track record of engineering expertise and flexibility in adapting to specific client requirements.

Tips: When evaluating injection molding suppliers, assess their certifications and industry standards compliance, such as ISO 9001, which indicates a dedication to quality management. Additionally, look for suppliers that invest in ongoing employee training and development, ensuring that the team is skilled in the latest techniques and technologies, ultimately leading to superior production outcomes. Engaging with suppliers who prioritize sustainable practices can also reflect their commitment to excellence in both quality and environmental responsibility.

When selecting potential injection molding vendors, it’s crucial to ask the right questions to ensure they can meet your project's needs effectively. First, inquire about their experience with various materials and technologies. Understanding a vendor's proficiency in handling different types of plastics, as well as their familiarity with the latest injection molding innovations, can give you insight into their capabilities. Additionally, it’s important to assess their knowledge of injection molding simulation software, which can play a significant role in optimizing the design and production process.

Another key area to explore is their approach to supply chain management, especially in light of recent industry disruptions. Questions about how they mitigate risks associated with raw material availability and their strategies for maintaining operational continuity are essential. With the injection molding machine market projected to reach USD 18,147.9 million by 2033, vendors who can demonstrate effective supply chain strategies and innovations will be better positioned to support your projects. Engaging in these discussions helps ensure that you choose a vendor who not only meets your technical requirements but can also adapt to an ever-evolving market landscape.

| Criteria | Details | Importance Level | Innovative Techniques |

|---|---|---|---|

| Material Quality | Use of high-grade thermoplastics | High | Advanced resin formulations |

| Technology | Utilization of precise CNC machines | High | Integration of AI for process optimization |

| Lead Time | Speed from design to production | Medium | Just-in-time production capabilities |

| Cost Effectiveness | Competitive pricing without compromising quality | High | Use of sustainable materials to reduce waste |

| Customization Ability | Flexibility in producing custom designs | Medium | Modular tool design for rapid changes |

| Quality Assurance | Rigorous testing and inspections | High | Data-driven quality control processes |

In today's competitive landscape, leveraging technology in the supplier selection process is crucial for achieving excellence in injection molding. According to a report by Grand View Research, the global injection molding market size is expected to reach USD 400 billion by 2025, highlighting the increasing demand for precision and efficiency. To meet these demands, companies are turning to innovative software solutions that enhance supplier vetting, streamline communication, and ensure quality standards are met.

Tip 1: Utilize Supplier Evaluation Software

To enhance your supplier selection process, consider implementing evaluation software that benchmarks potential suppliers against critical criteria such as quality certifications, production capacity, and lead times. This data-driven approach can significantly minimize risk and streamline the onboarding of new suppliers.

Tip 2: Integrate AI and Machine Learning

Employ AI-driven analytics to assess supplier performance metrics, enabling real-time adjustments to your supply chain strategy. This not only improves decision-making speed but also fosters long-term partnerships with reliable suppliers who meet evolving demands.

The integration of technology in supplier selection not only boosts the efficiency of the injection molding process but also ensures that quality is maintained, ultimately contributing to a company’s overall excellence.

Building long-term relationships with reliable injection molding partners is essential for achieving excellence in manufacturing. Trust and communication form the backbone of these partnerships, enabling companies to collaborate on innovations and share best practices. When both parties understand each other's capabilities and limitations, they can work together toward common goals, resulting in high-quality products and minimized lead times. Firms that invest in strong relationships with their partners can leverage shared resources and expertise, leading to better problem-solving and adaptability in a rapidly changing market.

Furthermore, selecting the right injection molding partner is crucial for sustaining quality and performance. Companies should seek partners who prioritize not only technological advancements but also transparent processes and ethical practices. This alignment fosters a culture of accountability and continuous improvement. By nurturing these partnerships, businesses can streamline their operations, increase efficiency, and ultimately enhance their overall competitiveness in the industry. In a landscape filled with challenges, strong partnerships stand out as key drivers for success, paving the way for innovation and excellence in injection molding practices.

Evaluating supplier performance is crucial in the injection molding industry, where excellence is defined by precision, consistency, and innovation. Establishing a set of key performance indicators (KPIs) can significantly enhance the assessment process. Metrics such as on-time delivery, defect rates, and production efficiency provide a concrete basis for evaluating a supplier's reliability and quality. Regular performance reviews against these metrics foster a culture of continuous improvement, enabling suppliers to understand areas that need enhancement and encouraging them to innovate.

Another effective strategy is to implement a feedback loop between manufacturers and suppliers. This not only aids in identifying performance gaps but also encourages open communication, fostering a more collaborative relationship. Tools like scorecards can help visualize supplier performance over time, allowing manufacturers to pinpoint trends and patterns that may require attention. This data-driven approach not only empowers suppliers to meet industry standards but also fuels ongoing innovation, ultimately leading to better products and services in the injection molding sector.