The rapid evolution of manufacturing practices is significantly influenced by innovations in molding products. As the industry adapts to advanced technologies and changing market demands, the global molding products market is projected to grow exponentially, reaching an estimated value of $9 billion by 2025. According to a recent report by MarketsandMarkets, the increasing application of molding processes across various sectors, including automotive, electronics, and consumer goods, is fueling this growth.

Furthermore, advancements in materials and production techniques are enhancing the efficiency and effectiveness of molding products, enabling manufacturers to meet the rising expectations for quality and sustainability. With the integration of smart manufacturing solutions and automation, companies are poised to capitalize on the benefits of these innovative products, driving down costs while improving output.

As the market continues to expand, molding products are set to revolutionize traditional manufacturing approaches, positioning businesses to thrive in an increasingly competitive landscape.

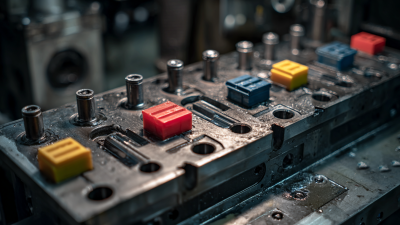

The molding technology landscape is undergoing a significant transformation, driven by innovative advancements that are expected to propel the market toward an impressive $9 billion growth by 2025. Key innovations in materials, techniques, and automation are revolutionizing traditional manufacturing processes. Enhanced precision, reduced waste, and improved cost efficiencies are at the forefront of these developments, enabling manufacturers to meet increasingly complex demands.

Among the leading trends is the rise of smart molding solutions that leverage advanced robotics and artificial intelligence to optimize production lines. These technologies not only heighten operational efficiency but also allow for greater customization in product design. Moreover, the integration of sustainable practices within molding processes is gaining traction, as manufacturers seek to reduce their environmental footprint while enhancing product durability and quality, thereby attracting a broader market segment focused on sustainability. This dynamic shift marks the beginning of a new era in manufacturing, setting the stage for robust growth in the coming years.

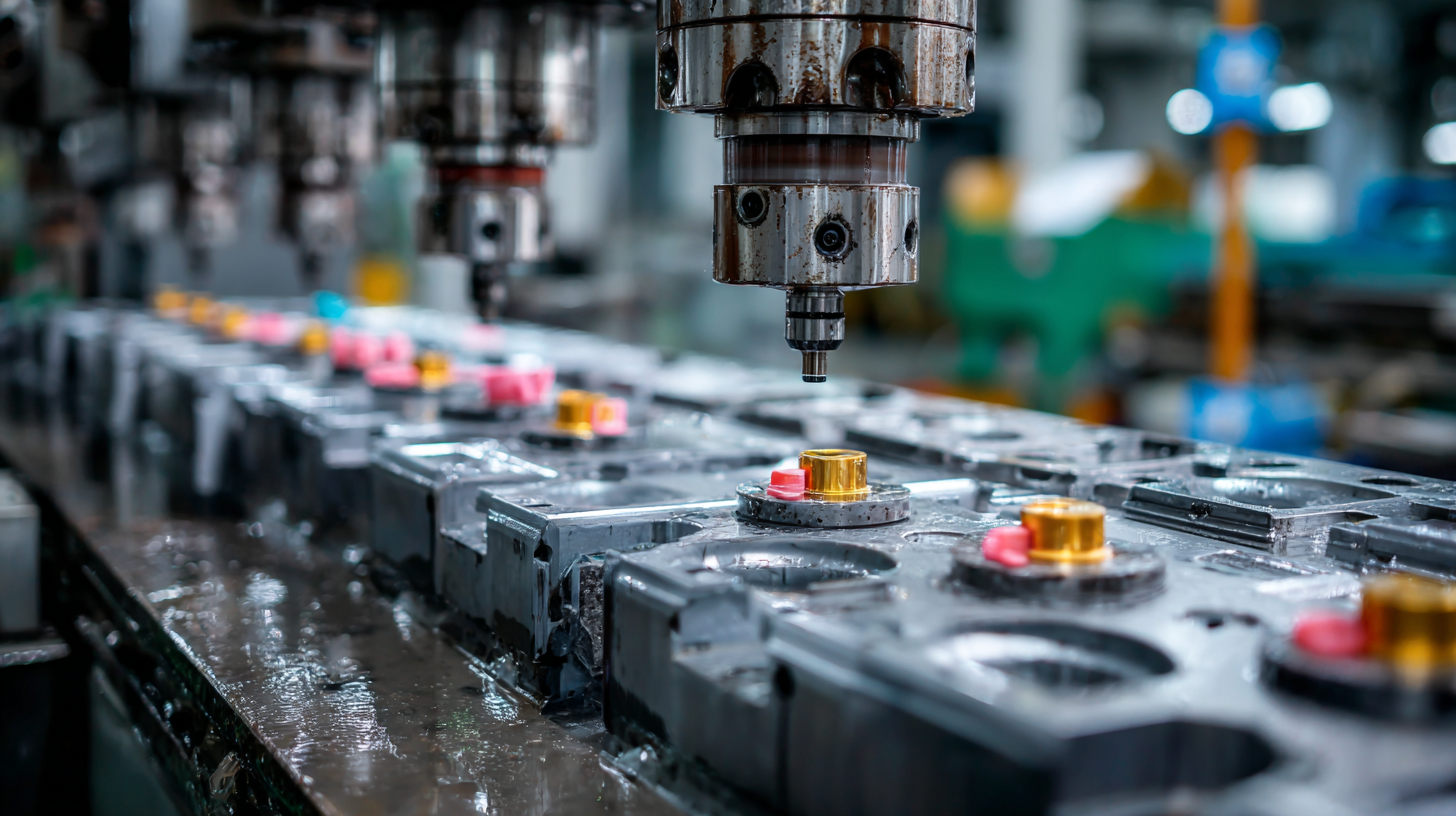

The advent of automation in molding production is transforming the landscape of manufacturing, significantly enhancing both operational efficiency and cost-effectiveness. Automated systems, such as robotic arms and programmable logic controllers (PLCs), streamline repetitive tasks and minimize human error. By rapidly executing precise movements, these machines not only speed up the production process but also ensure a higher quality of molded products. This increased precision leads to less material wastage, which ultimately contributes to a lower overall production cost.

Moreover, the integration of advanced technologies like Artificial Intelligence (AI) and the Internet of Things (IoT) is further amplifying the benefits of automation in molding. AI-driven analytics can predict machine failures before they occur, allowing for proactive maintenance that reduces downtime. Additionally, IoT connectivity enables real-time monitoring of production processes, providing manufacturers with insights that drive continuous improvement. The combination of these technologies is poised to revolutionize the molding industry, positioning companies to meet the growing demands of a competitive market.

| Molding Product | Market Growth (USD Billion) | Automation Efficiency (%) | Cost Reduction (%) | Year of Introduction |

|---|---|---|---|---|

| Advanced Injection Molding | 3.0 | 20 | 15 | 2023 |

| 3D Printing in Molding | 2.5 | 35 | 25 | 2024 |

| Robotic Mold Handling | 1.5 | 40 | 20 | 2023 |

| Smart Molding Machines | 1.0 | 30 | 18 | 2025 |

| Hybrid Molding Technologies | 1.0 | 33 | 22 | 2025 |

The rise of sustainable materials in molding is reshaping the future of manufacturing, as industries increasingly prioritize eco-friendly practices. According to a recent market research report by Smithers, the global green materials market is projected to grow from $11 billion in 2020 to $31 billion by 2027, highlighting a shift towards sustainability that manufacturers can no longer afford to ignore. Innovations in biodegradable plastics and renewable resource-based composites are at the forefront of this transformation, showcasing their potential in reducing environmental impact while maintaining product durability.

One intriguing development is the integration of recycled materials into traditional molding processes. For example, Polylactic Acid (PLA), derived from cornstarch, is gaining traction for its ability to decompose, thus minimizing landfill waste. A survey by the American Chemistry Council indicated that approximately 50% of manufacturers are now exploring bioplastics to align with sustainability goals. These advancements not only support environmental preservation but can also attract eco-conscious consumers, enhancing brand loyalty.

Tip: When considering sustainable materials, evaluate the lifecycle of products and their biodegradability, ensuring that the chosen materials align with your company's sustainability objectives. Emphasizing transparent sourcing and production methods can significantly enhance your brand's reputation in a competitive market.

The manufacturing sector is undergoing a significant transformation driven by technological advancements, particularly in molding processes. Digital transformation, characterized by the integration of artificial intelligence (AI) and the Internet of Things (IoT), is enhancing precision and efficiency in molding applications. According to a recent market analysis, the molding industry is projected to grow by $9 billion by 2025, largely attributed to these innovative technologies.

AI algorithms are now capable of predicting potential defects during the molding process, allowing manufacturers to optimize production in real-time. The 2023 Smart Manufacturing Report highlights that companies implementing AI solutions have seen a reduction in scrap rates by up to 30%. IoT devices are also playing a crucial role by monitoring machine health and automating maintenance schedules, resulting in reduced downtime and increased productivity.

**Tip:** For manufacturers looking to adopt these technologies, start small by integrating IoT sensors into existing machinery to gather data. This will provide insights into operational efficiency and inform future investments in AI-driven solutions.

Additionally, investing in training programs that equip the workforce with digital skills will be essential to harness the full potential of these technologies. The 2022 Workforce Development Survey reports that organizations with well-trained employees in digital tools experienced 25% higher productivity levels, demonstrating that human capital is as crucial as technological advancements in the industry.

This chart illustrates the projected market growth of the top 5 molding products leading to a 9 billion market growth by 2025. The data reflects the integration of AI and IoT technologies enhancing precision in manufacturing processes.

The molding industry is experiencing significant advancements, particularly within the automotive and electronics sectors. One of the most notable trends is the growth of in-mold electronics, with the market estimated at USD 213.50 million in 2024, projected to leap to USD 2,090.42 million by 2033. This growth highlights the increasing integration of electronics directly into molded structures, enabling multifunctional and innovative designs that cater to modern consumer demands.

Additionally, the molded interconnect device (MID) market is set to expand rapidly, with forecasts indicating a value of USD 5.8 billion by 2035, driven by a compound annual growth rate (CAGR) of 4.9% over the next decade. This innovation not only reduces assembly time but also enhances product durability and performance, making it an attractive option for manufacturers. The demand for precision components, particularly in the medical device industry, is further fueling the growth of thermoplastic micro molding, which is witnessing an upsurge as industries strive for more compact and efficient solutions. As these molding technologies evolve, they are undeniably revolutionizing manufacturing processes across the board.