In the rapidly evolving landscape of manufacturing, the choice of the right injection machine mold has become a critical factor that influences not only production efficiency but also the overall quality of the end product. According to a recent report by Smith & Associates, the global injection molding market is expected to reach $300 billion by 2025, underscoring the importance of precision and quality in mold design and selection. Industry experts emphasize that a well-chosen injection machine mold can significantly reduce waste and production costs while enhancing product durability and performance.

Dr. Emily Roberts, a leading figure in the field of injection molding technology, states, "Selecting the appropriate injection machine mold is pivotal; it can make or break the success of a manufacturing project." Her insights highlight the necessity for manufacturers to consider various factors, such as material compatibility, mold design complexity, and lead time. As companies strive for greater efficiency and sustainability, understanding the key elements in selecting an injection machine mold is essential for staying competitive in this booming industry.

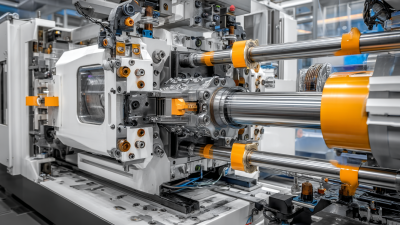

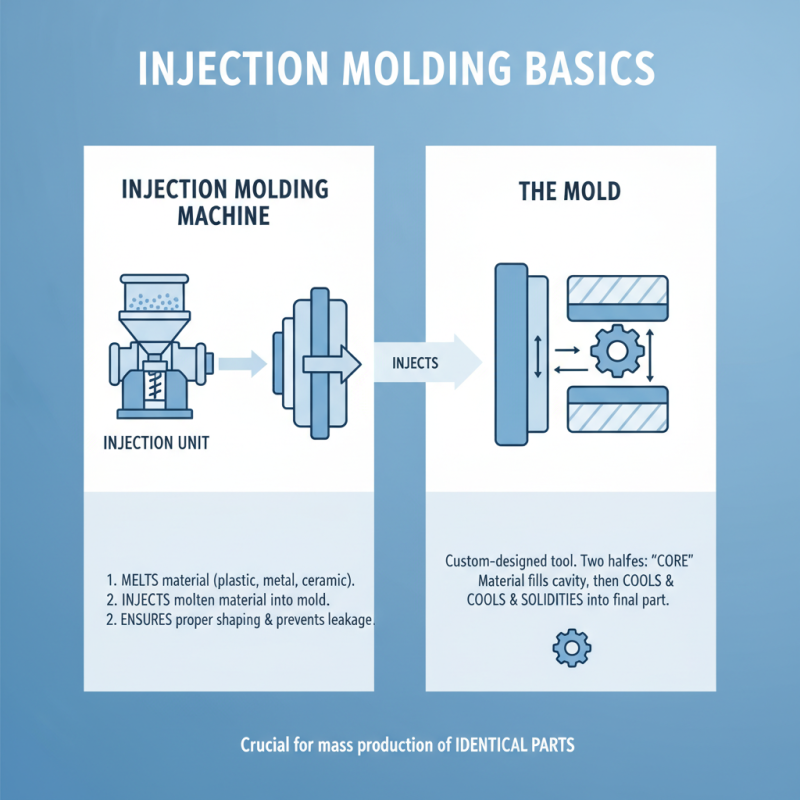

Injection molding is a widely used manufacturing process that involves creating parts by injecting molten material into a mold. Understanding the basics of injection molding machines and molds is crucial for anyone looking to invest in this technology for their projects. An injection molding machine consists of two main components: the injection unit and the clamping unit. The injection unit melts the chosen material and injects it into the mold, while the clamping unit holds the mold closed under pressure during the injection process to ensure proper shaping and prevent leakage.

Molds are typically made from metals such as steel or aluminum and are custom-designed to create specific shapes and designs. Factors that influence the design of the mold include the part geometry, the type of material being used, and the production volume. It's essential to consider these elements carefully, as they will impact both the quality of the final product and the efficiency of the production process. Proper mold design not only reduces cycle times and material waste but also improves the overall durability of the mold itself, extending its lifespan and functionality for future projects.

When selecting injection machine molds for your projects, several key factors must be considered to ensure optimal performance and efficiency. First and foremost, assess the material requirements of your project. Different materials, such as thermoplastics and thermosets, have unique characteristics that influence the mold design and construction. Understanding the properties of the material will help determine the type of mold needed and ensure that the end products meet quality standards.

Another critical factor is the mold design and complexity. Consider the part geometry and the level of detail required for the finished product. More complex designs may necessitate molds with intricate details, which can increase manufacturing costs and lead times. Additionally, evaluate the expected production volume, as this will influence the type of mold to select—whether opting for a single cavity mold for lower volumes or a multi-cavity mold for mass production. Furthermore, take into account the cycle time and maintenance requirements, as these aspects directly impact overall productivity and operational efficiency. By carefully weighing these factors, you can make a more informed decision that aligns with your project's specific needs.

This bar chart illustrates the key factors to consider when selecting injection machine molds based on their importance level.

When selecting an injection machine mold for your projects, understanding the various types and their applications is crucial. The most common types of injection molds include single cavity molds, multi-cavity molds, and family molds. Single cavity molds produce one part per cycle, making them ideal for low-volume production or prototyping where simplicity is key. Multi-cavity molds, on the other hand, allow for the production of multiple identical parts in a single cycle, enhancing efficiency for higher volume productions. Family molds can simultaneously create different parts that make up an assembly, streamlining the injection molding process for projects that require integrated components.

In addition to the basic types, you should also consider specialized molds such as hot runner and cold runner molds. Hot runner molds keep the plastic in a molten state as it travels through the runner system, reducing waste and improving cycle times. They are excellent for high-volume runs where consistent quality is crucial. Cold runner molds tend to be simpler and more cost-effective for low-volume projects but may require additional trimming work due to excess plastic. Another specialized mold type is the insert mold, which allows the incorporation of other materials or components within the molded part, offering versatility in design and function.

Each mold type presents unique advantages tailored to specific project needs, making it essential to evaluate them thoroughly before making your choice.

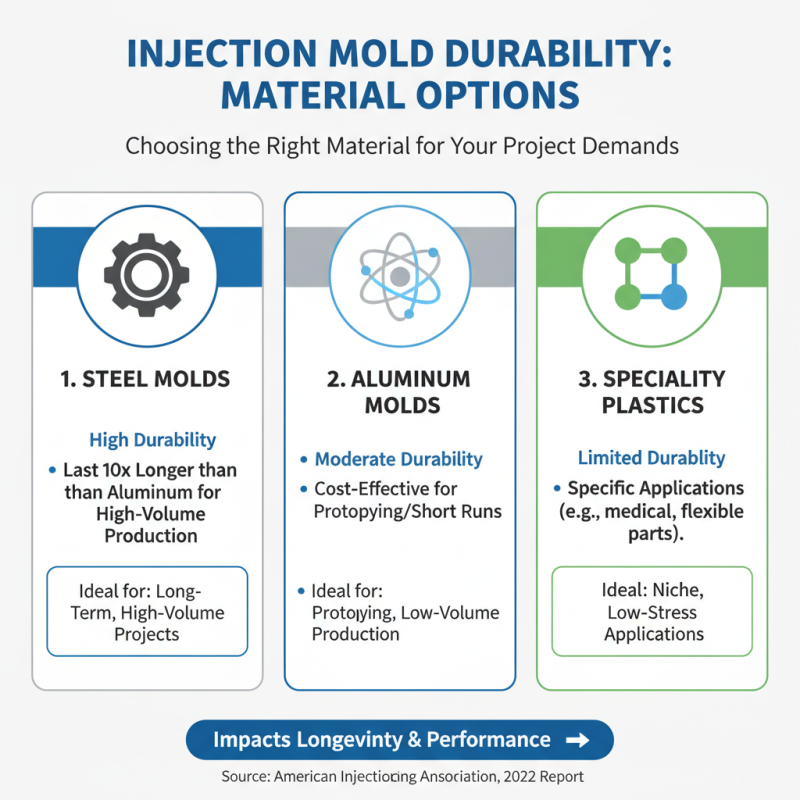

When evaluating material options for injection mold durability, it is crucial to consider the specific demands of your projects. Materials commonly used in injection molds include steel, aluminum, and various types of specialty plastics. According to a 2022 report by the American Injection Molding Association, the choice of mold material significantly impacts the longevity and performance of the molds. For instance, steel molds can last up to 10 times longer than aluminum molds when subjected to high-volume production, making them ideal for projects requiring high durability.

In terms of material characteristics, the hardness and wear resistance of steel molds offer distinct advantages in high-temperature applications and processes involving abrasive materials. A study published in the Journal of Materials Processing Technology revealed that using high-carbon steel for molds can increase lifespan under stress conditions by as much as 70%. Conversely, aluminum molds, while lighter and easier to machine, may suffer from quicker wear when used for long production runs, thus increasing costs over time due to the need for replacement and maintenance.

Thermoplastic elastomers (TPE) and composite materials are also gaining traction in the injection molding industry. These materials can provide a balance between flexibility, durability, and cost-effectiveness. According to a report by Grand View Research, the global demand for TPE in injection molding is projected to grow by 5.7% annually through 2028, highlighting their increasing importance in applications that demand both resilience and versatility. In summary, the choice of material directly influences mold performance and durability, making it essential to align material selection with project requirements and expected production volumes.

Maintaining injection molding equipment is crucial for ensuring optimal performance and longevity. Regular cleaning is one of the best practices that operators should adopt. Contaminants such as dust, plastic residue, and lubricants can build up and affect the machine's efficiency. A thorough cleaning routine not only helps in maintaining the quality of the produced items but also prevents machine wear and tear, which could lead to costly repairs or replacements in the long run.

In addition to cleaning, regular inspections of the mold and associated components are essential. Operators should check for any signs of wear, such as cracks or erosion, and ensure that all moving parts are well-lubricated to minimize friction. A proactive approach to maintenance, including routine checks and timely replacement of worn parts, can significantly reduce downtime and increase productivity. Moreover, keeping detailed records of maintenance activities can help identify recurring issues, allowing for more effective planning and resource allocation in future projects.

| Dimension | Material Type | Cooling System | Maintenance Frequency | Recommended Practices |

|---|---|---|---|---|

| Standard | Steel | Single Circuit | Monthly | Inspect seals and lubrication. |

| Custom | Aluminum | Dual Circuit | Biweekly | Clean regularly to avoid clogs. |

| Large | Hardened Steel | Water-cooled | Quarterly | Check for wear and replace parts as needed. |

| Small | Brass | Air-cooled | Weekly | Lubricate moving parts regularly. |