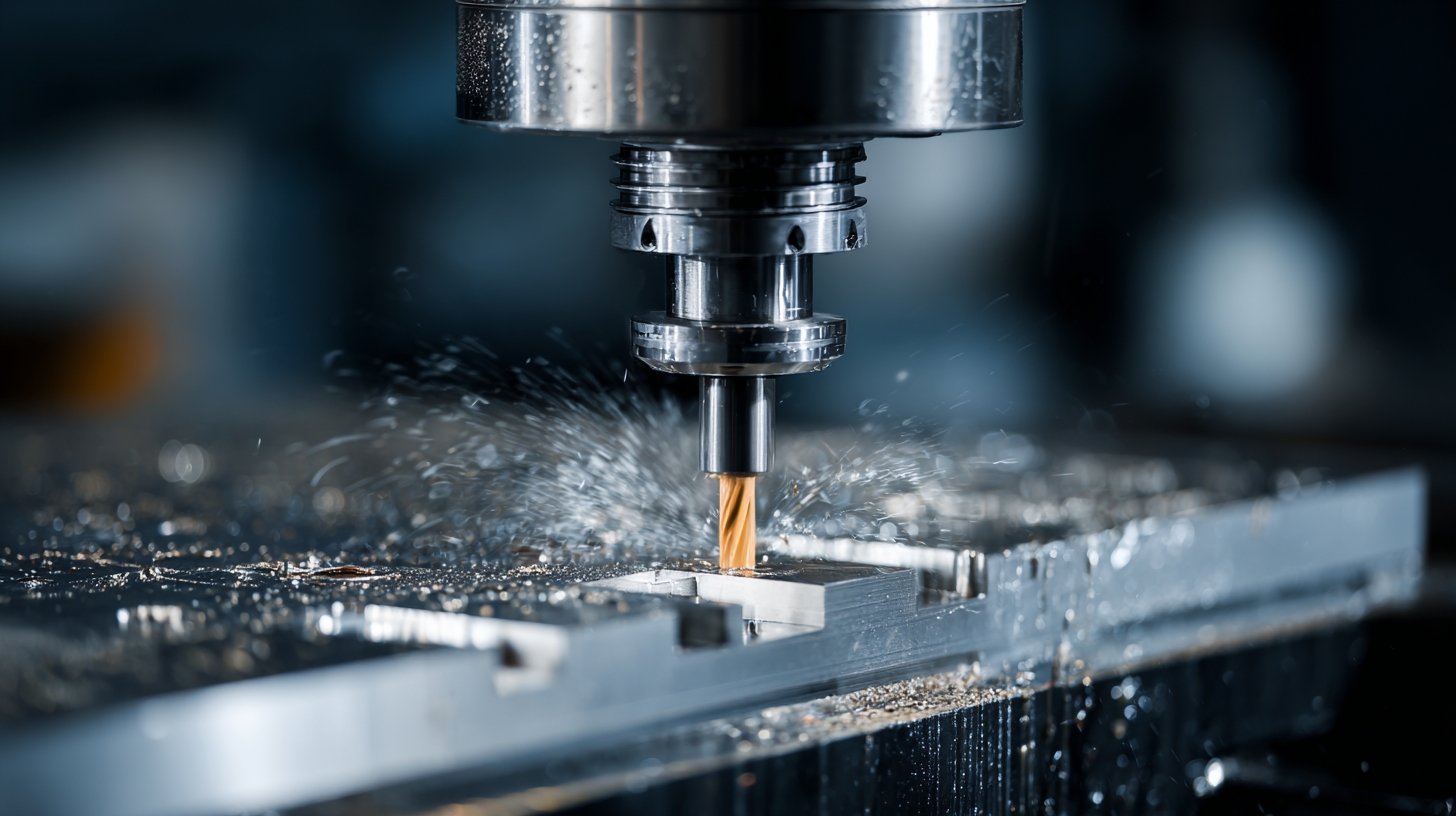

In today's competitive manufacturing landscape, optimizing processes is essential for achieving operational excellence and cost efficiency. Recent industry reports indicate that manufacturers utilizing advanced techniques such as machine injection can enhance production speeds by up to 30%, while simultaneously reducing material waste by 15%. Machine injection methods allow for greater precision and consistency in product output, directly impacting quality control and customer satisfaction. As companies strive to meet increasing demand and stringent sustainability goals, leveraging machine injection not only presents a pathway for improved productivity but also a strategic advantage in maintaining market relevance. This blog will explore actionable tips and methodologies to effectively optimize your manufacturing process through the implementation of machine injection techniques, ensuring that your operations remain both efficient and innovative.

Machine injection techniques play a pivotal role in modern manufacturing, offering precision and efficiency that significantly enhance production processes. According to a report by the International Journal of Advanced Manufacturing Technology, utilizing advanced injection molding techniques can improve cycle times by up to 40%, enabling manufacturers to produce higher volumes of goods while minimizing waste. This optimization is achieved through various methods, including the use of multi-component injection, which allows for the blending of different materials to create complex parts in a single cycle.

The adoption of automated machine injection systems is on the rise, driven by an increasing demand for quality and consistency in manufacturing outputs. A 2022 survey by the Manufacturing Institute indicated that 67% of manufacturing leaders believe that investing in automation—including injection molding technology—directly correlates to improved product quality and reduced production costs. Furthermore, the integration of smart technologies into injection processes, such as IoT-enabled sensors, can provide real-time monitoring and adjustments during production, ensuring that both efficiency and quality standards are maintained. This convergence of technology and manufacturing processes exemplifies the transformative potential of machine injection techniques in the industry.

| Injection Technique | Material Used | Cycle Time (seconds) | Yield Rate (%) | Cost per Unit ($) |

|---|---|---|---|---|

| Thermoplastic Injection | Polypropylene | 15 | 95 | 0.50 |

| Thermoset Injection | Epoxy Resin | 20 | 90 | 0.80 |

| Die Casting | Aluminum Alloy | 25 | 92 | 1.20 |

| Injection Blow Molding | Polyethylene Terephthalate | 30 | 89 | 0.70 |

Optimizing your manufacturing process through machine injection techniques can significantly enhance efficiency and output quality. One of the primary benefits of this optimization is reduced material waste. By using advanced injection molding methods, manufacturers can ensure precise material distribution and minimize leftover excess, thus lowering production costs and contributing to a more sustainable operation.

Moreover, machine injection techniques streamline production timelines. Automation and precision involved in injection processes lead to faster cycles and consistent product quality. This acceleration not only keeps up with market demands but also allows manufacturers to redirect their resources towards innovation and development. Ultimately, the integration of these techniques can give companies a competitive edge in an ever-evolving manufacturing landscape.

To achieve an efficient machine injection system, it's crucial to focus on key components that drive performance and sustainability. The energy consumption variability in injection molding processes has become a hot topic, with recent reviews indicating that current life cycle assessment (LCA) methodologies may underestimate energy utilization. As manufacturers strive for efficiency, understanding these energy metrics can provide significant insights. The global market for plastic injection molding machines is experiencing robust growth, valued at approximately $7.63 billion in 2023 and projected to expand at a CAGR of 5% through 2032. This growth reflects increased demand for lightweight components and sustainable materials, underscoring the need for optimized injection techniques that reduce energy waste.

Additionally, advancements in control technologies, such as deep reinforcement learning for hydraulic servo systems, are enhancing precision in injection molding processes. Systems incorporating such innovations can improve position control accuracy, a critical factor for minimizing energy consumption. Markets are also observing a remarkable uptick in regions like India, where projections indicate growth from $830.9 million in 2025 to nearly $1.76 billion by 2035, marking a CAGR of 8.0%. These trends highlight that investing in modern injection techniques not only increases production efficiency but also aligns with sustainability goals and market demands.

Implementing machine injection techniques can significantly enhance the efficiency of manufacturing processes, but several common challenges can impede successful integration. One of the foremost challenges is the high initial investment required for advanced machinery. According to a report from the International Society of Automation (ISA), approximately 70% of manufacturers cite capital expenditure as a major barrier to adopting new technologies. This financial burden can deter companies from embracing machine injection techniques, despite the long-term cost savings and productivity gains they offer.

Another challenge is the necessity for skilled labor to operate sophisticated injection machinery. The Manufacturing Institute indicates that there will be a projected shortage of 2.1 million manufacturing jobs by 2030 due to an aging workforce and insufficient training programs. This gap in expertise can lead to operational inefficiencies, as employees may struggle to effectively manage and maintain new injection systems. Furthermore, without proper training, the risk of machine malfunctions increases, leading to production delays and increased costs.

Finally, the integration of machine injection techniques into existing workflows poses its own set of difficulties. A study by PwC found that 65% of manufacturing leaders face issues related to the compatibility of new technology with legacy systems, which can result in disruptions during the transition phase. It is essential for companies to carefully plan and pilot these technologies to mitigate implementation risks and ensure a smoother integration process.

In today's rapidly evolving manufacturing landscape, the integration of advanced machine injection techniques is becoming increasingly vital for achieving enhanced efficiency. One of the significant future trends is the adoption of smart manufacturing technologies, which involve the use of the Internet of Things (IoT) and artificial intelligence (AI) in the injection molding process. These technologies enable real-time monitoring and data collection, allowing manufacturers to make informed decisions that optimize production schedules and reduce waste.

To stay ahead in this competitive industry, consider these tips: Firstly, invest in training your workforce to utilize new technologies effectively. Skilled employees can significantly leverage the benefits of machine injection systems and contribute to innovations. Secondly, focus on the development of sustainable practices within your injection processes. By incorporating eco-friendly materials and energy-efficient machines, manufacturers can not only reduce their carbon footprint but also appeal to the growing market segment that values sustainability.

Lastly, leveraging predictive maintenance tools can transform your manufacturing operations. By anticipating machine failures before they occur, manufacturers can ensure seamless production and minimize downtime. Embracing these trends not only enhances efficiency but also positions manufacturers to meet future consumer demands effectively.