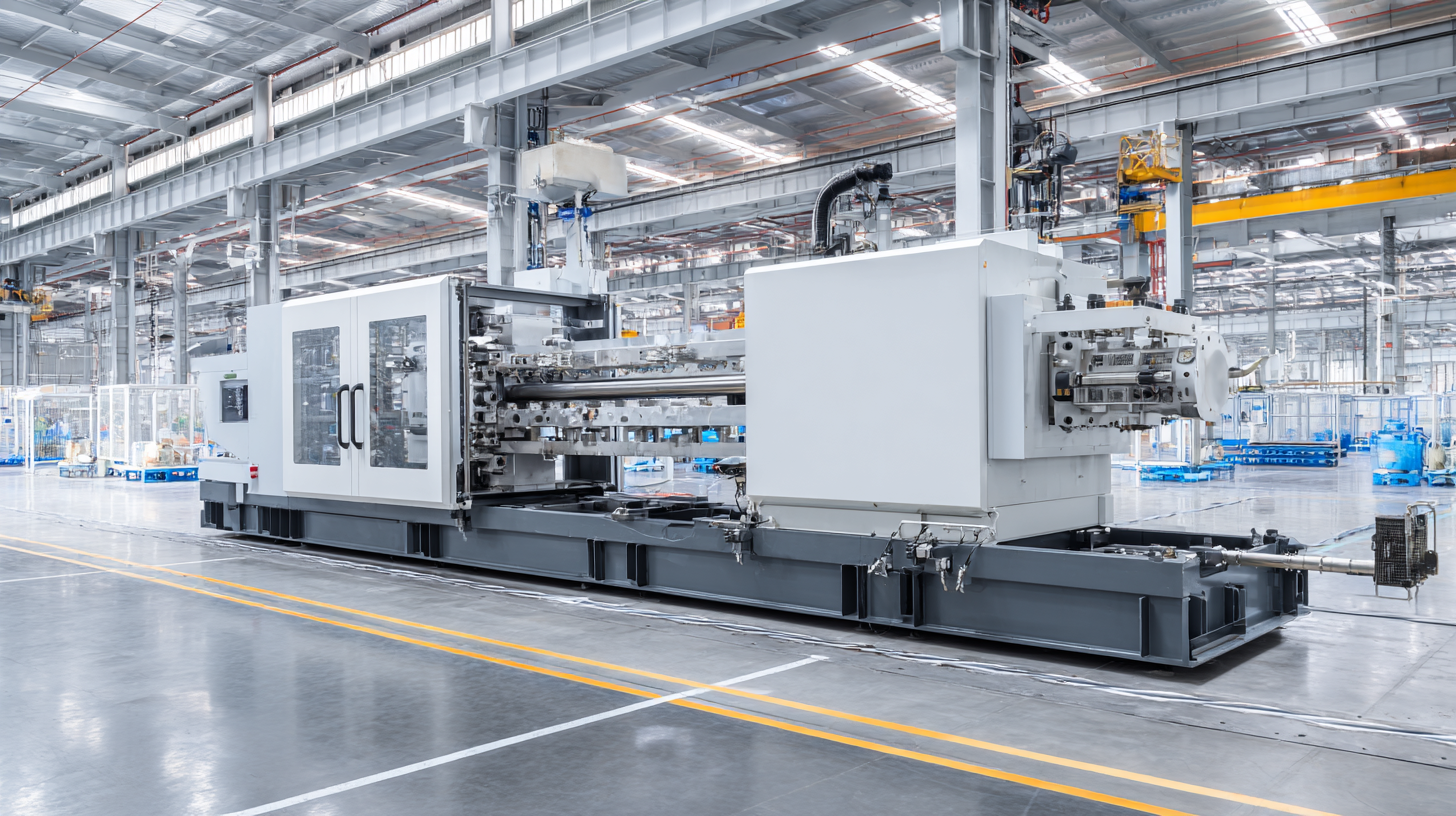

The injection moulding process is a cornerstone of modern manufacturing, playing a pivotal role in producing high-precision plastic components across various industries. According to a report by MarketsandMarkets, the global injection moulding market is expected to reach $361.5 billion by 2026, growing at a CAGR of 4.6% from 2021. This growth is driven by the increasing demand for lightweight and durable materials that can be produced efficiently at scale. As businesses strive to enhance their competitive edge, mastering the intricacies of the injection moulding process becomes essential. From optimizing machine settings to selecting the right materials, understanding each phase of this process can significantly impact product quality and production costs. In this ultimate guide, we will explore the essential strategies and best practices to help your business leverage the full potential of injection moulding, ensuring you stay ahead in a rapidly evolving market.

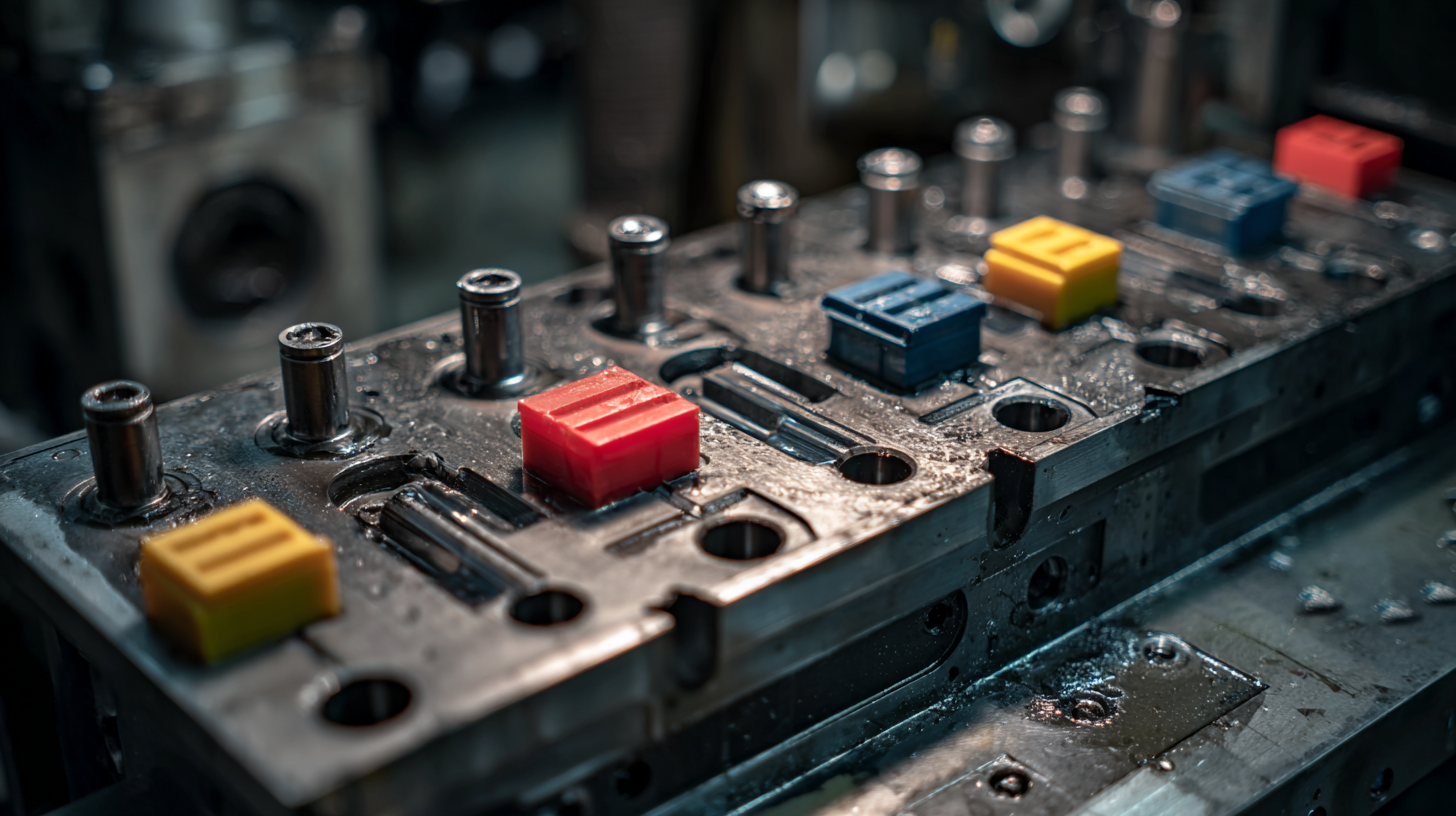

Injection moulding is a widely used manufacturing process that allows businesses to create complex plastic parts with precision and efficiency. It involves injecting molten plastic into a mould, where it cools and solidifies into the desired shape. There are several key definitions to understand, including thermoplastics, which can be re-melted and reformed, and thermosetting plastics, which harden permanently after being shaped. Additionally, different types of injection moulding techniques, such as bi-injection and gas-assisted moulding, can be utilized depending on the project requirements.

When working with the injection moulding process, consider these tips to enhance your results. Firstly, choose the right material for your specific application, as different plastics offer varied properties such as strength, flexibility, and thermal resistance. Secondly, maintain your equipment regularly to prevent downtime and ensure consistent quality in production. Lastly, invest time in designing efficient moulds that minimize waste and optimize production speed, helping to streamline your operations while saving costs.

Understanding the nuances of injection moulding types, including single and multi-cavity moulds, can also make a significant difference in production efficiency. Be sure to assess your production volumes and scalability needs when deciding on the design, as this can impact lead times and overall project feasibility. Implementing these strategies can empower your business to master the injection moulding process effectively.

This chart illustrates the relationship between manufacturing time and production volume in the injection moulding process. It highlights how increasing production volume can affect the time taken for manufacturing, helping businesses optimize their processes.

The injection moulding process plays a pivotal role in the global plastics market, serving as a cornerstone for manufacturers and businesses looking to optimize production efficiency and reduce costs. This method not only streamlines the creation of complex plastic parts but also empowers companies to meet growing consumer demands through quicker turnaround times. As industries expand, the need for precision and scalability in manufacturing becomes even more essential, driving the economic significance of injection moulding.

Moreover, the economic impact of injection moulding extends beyond the manufacturing process itself. It stimulates job creation across various sectors, from design and engineering to assembly and quality control. Countries with a strong foothold in plastic manufacturing benefit significantly from this process, often seeing increased export capabilities and enhanced competitive positioning in the global market. As businesses invest in more advanced moulding technologies, they contribute to innovation, efficiency, and sustainability initiatives, further solidifying injection moulding's critical role in the global economy.

| Region | Market Size (USD Billion) | Growth Rate (%) | Key Applications | Challenges |

|---|---|---|---|---|

| North America | 30.5 | 3.5 | Automotive, Consumer Goods | Regulatory Compliance |

| Europe | 28.7 | 2.9 | Packaging, Electronics | Material Shortages |

| Asia-Pacific | 50.2 | 6.7 | Medical Devices, Toys | Skilled Labor Shortage |

| Latin America | 9.8 | 4.2 | Construction, Agriculture | Economic Instability |

| Middle East & Africa | 7.4 | 3.1 | Packaging, Construction | Infrastructure Challenges |

Injection moulding is a critical process for many businesses keen on optimizing their production efficiency. According to a report by MarketsandMarkets, the global injection moulding market is expected to reach $350 billion by 2025, underscoring the rising importance of mastering this technique for competitive advantage. To ensure your business remains at the forefront, consider these essential tips.

First, focus on material selection. The right material can significantly enhance product quality and reduce waste. For example, using thermoplastic materials can lead to a 20% increase in production efficiency due to their ease of processing and recycling capabilities.

Second, prioritize machine maintenance. Regular maintenance can prevent unexpected downtimes, which studies show can lead to an estimated 5% increase in overall operational efficiency. Establish a checklist to ensure that every part, from nozzles to heaters, is functioning correctly.

Lastly, invest in employee training. Properly trained personnel are crucial for optimizing the injection moulding process. Research from Deloitte suggests that companies who invest in training programs see a productivity increase of up to 30%, demonstrating the direct relationship between skilled workers and manufacturing efficiency. By implementing these strategies, you can significantly enhance your injection moulding operations, driving your business toward higher productivity and profitability.

Quality control is a critical component of the injection moulding process, ensuring that products meet industry standards and customer expectations. In order to maintain high-quality outputs, businesses should adopt comprehensive quality control practices throughout the production cycle. This begins with meticulous material selection, where polymers and additives must be compatible and of high quality to prevent defects during the moulding process. Regularly inspecting raw materials before they're fed into the machine can significantly reduce the risk of compromised product quality.

Moreover, implementing industry standards such as ISO 9001 can help streamline quality assurance practices. This framework encourages organizations to establish clear quality objectives, maintain accurate documentation, and perform regular audits. Businesses should also invest in advanced monitoring technologies, like in-line inspection systems, which can detect discrepancies in real-time, allowing for immediate adjustments. By adhering to best practices in quality control, companies not only enhance their product reliability but also optimize their operational efficiency, ultimately leading to increased customer satisfaction and loyalty.

In the context of modern manufacturing, sustainability in the injection moulding process is becoming a significant focus for businesses aiming for a greener future.

As the industry grapples with the pressing issue of plastic waste, innovative solutions such as bio-based, biodegradable, and edible materials are emerging.

These advancements not only address environmental concerns but also align with the growing consumer preference for eco-friendly products. For instance, recent innovations in alternative materials—like starch-blended polymers and algae-based bioplastics—have shown promising potential for reducing the ecological footprint of traditional plastics.

Furthermore, companies are exploring advancements in green technologies within injection moulding, enabling more efficient use of resources and energy. This shift is evident in the rising popularity of composite materials, which offer enhanced sustainability by utilizing recycled and bio-based elements. As markets expand, particularly in regions like India, industries are increasingly investing in eco-conscious practices and technologies.

By integrating these innovations, businesses can contribute significantly to the sustainability agenda, ensuring that injection moulding evolves in harmony with environmental stewardship and market demands.