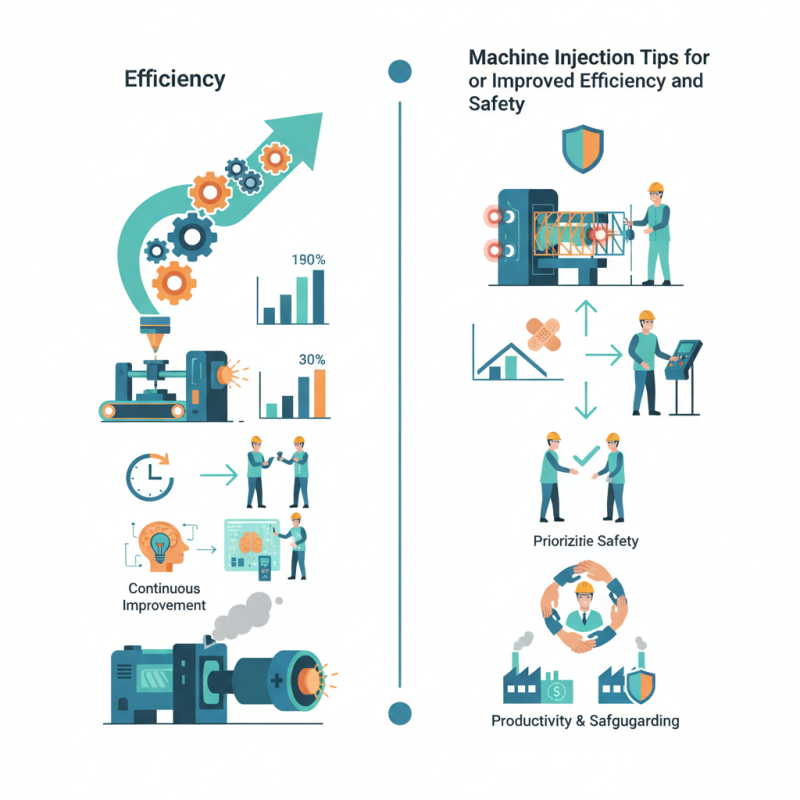

Machine injection is a critical process in various manufacturing sectors. With the right techniques, companies can enhance both efficiency and safety. According to a report by the International Society of Automation, 40% of production downtime is related to machine inefficiencies. This statistic highlights the importance of optimizing machine injection processes.

Experts, like Dr. Emily Carter, state, "The key to successful machine injection lies in continuous improvement." Her insights underline the necessity for ongoing training and updated practices. Implementing advanced safety measures can reduce injury rates. In fact, manufacturers that prioritize safety training see a 50% reduction in workplace incidents.

Despite these advancements, challenges remain. Many facilities still rely on outdated machinery. This often leads to inefficiencies that impact output. Companies must reflect on their practices and embrace modern solutions. Proper machine injection techniques can significantly improve production while safeguarding workers. Emphasizing efficiency and safety is not just beneficial; it is essential in today’s competitive landscape.

Machine injection plays a critical role in manufacturing. Understanding this process can significantly boost efficiency. Injection molding accounts for about 30% of all plastics produced. Proper machine settings can enhance cycle times. Poor calibration wastes materials and time. Adjusting temperature and pressure specifically can lead to optimal results.

Moreover, safety in machine injection is paramount. According to industry reports, up to 80% of accidents occur due to operator errors. Regular training and awareness can mitigate this risk. Implementing automated systems can also reduce human involvement. Machines must be maintained regularly to prevent malfunctions. Neglecting this can lead to costly downtime.

Yet, achieving perfect efficiency remains elusive. Operators often face challenges with wear and tear on machines. Small defects in equipment can lead to increased scrap rates. Continuous feedback loops are necessary for improvement. Overall, machine injection is essential, but it thrives on careful management and monitoring for both safety and efficiency.

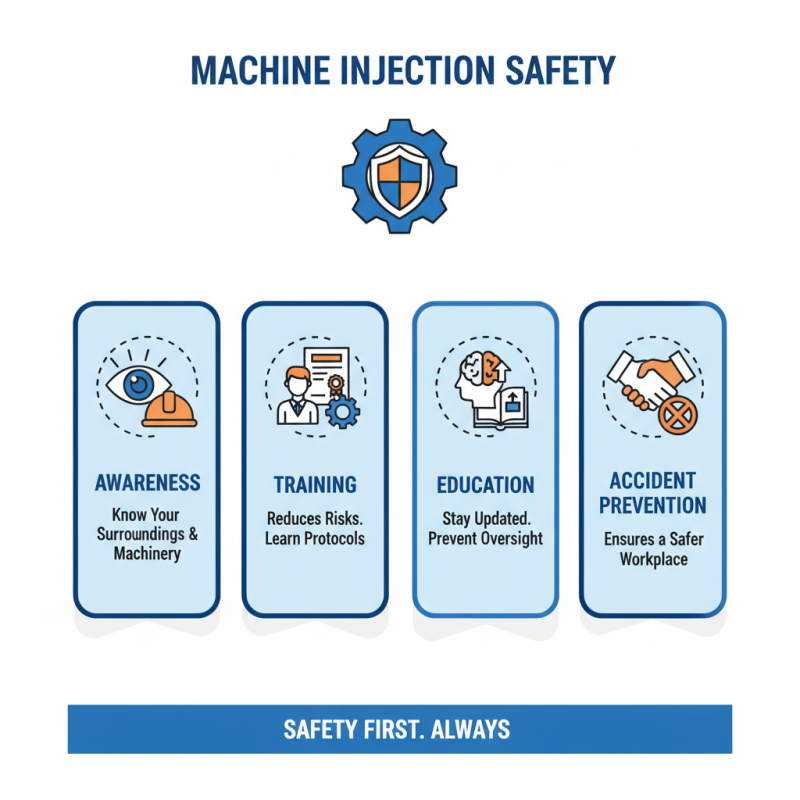

In machine injection processes, safety is a crucial aspect. Workers must be aware of their surroundings and the machinery they operate. Proper training can greatly reduce risks. Continuous education ensures that employees are updated on safety protocols. This can prevent accidents that might occur due to oversight.

Tips for safety include using personal protective equipment (PPE), such as gloves and goggles. Workers should always check their equipment before starting. Regular maintenance of machines is essential to avoid malfunctions. It's important to remain alert during operation. Taking breaks can help keep focus sharp.

Communication is key in an injection molding environment. Workers need to report any discrepancies immediately. Sometimes, the smallest oversight can lead to major issues. Creating a culture of safety encourages everyone to speak up. Learning from past incidents drives improvements.Safe practices are a collective responsibility, and vigilance is necessary for a secure workplace.

Optimizing performance in machine injection operations requires attention to several key areas. Regular maintenance of equipment is essential. Perform checks on hoses, nozzles, and filters. Any wear or damage can lead to inefficiency and safety risks. A simple visual inspection can reveal issues before they escalate. Don’t overlook small leaks; they can lead to larger operational problems.

Training personnel is another critical step. Operators should understand the machinery they are using. Proper training ensures they recognize potential hazards. Frequent refresher courses can help maintain a high level of awareness. Encourage operators to share their experiences. Learning from each other can improve overall safety.

Data monitoring plays a significant role in optimization. Collecting data on injection cycles helps identify trends. Anomalies can prompt immediate reviews. However, a reliance on data can become overwhelming. Balancing human insight with data analysis is crucial. Continuously reflecting on both is necessary for refining processes. This ongoing evaluation is where true improvements will emerge.

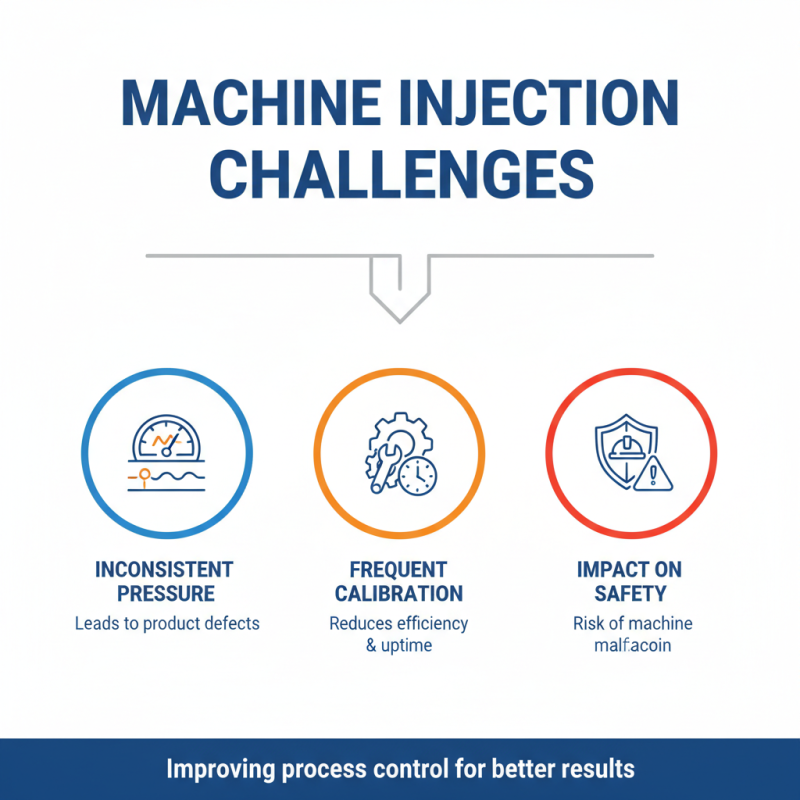

Machine injection can be tricky. Many operators face challenges that impact efficiency and safety. One common issue is inconsistent pressure during the injection process. Variations can lead to defects in the final product. Operators often need to calibrate machines frequently to maintain consistent results.

Another challenge is the risk of contamination. This can happen if the equipment is not cleaned properly. Regular maintenance is key to preventing issues. However, workers sometimes overlook this step due to time constraints. A well-defined cleaning schedule can help reduce these risks.

Training staff is also crucial. Without proper understanding, mistakes can occur easily. Workers should know the potential hazards involved in machine injection. Implementing routine safety drills can enhance awareness. Reflecting on past incidents can lead to better practices. Improvement often comes from learning and adapting.

The landscape of machine injection is evolving rapidly. Innovative technologies are playing a key role in enhancing efficiency. For example, advanced sensors and automation systems help streamline the injection process. These additions can reduce waste and optimize energy use, making operations more cost-effective.

Moreover, predictive maintenance is gaining traction. By using data analytics, machines can anticipate failures before they occur. This results in less downtime and smoother workflows. However, implementing such systems can be daunting. Companies may struggle with integration and employee training. Not everyone may embrace these changes.

Additionally, safety remains a significant concern. While new technologies reduce risks, they don’t eliminate them entirely. It's crucial to ensure that all operators are trained properly. The balance between innovation and safety requires careful reflection. Exploring these technologies can lead to improved practices, but challenges must be addressed head-on.