As industries continue to evolve, the demand for efficient and precise manufacturing processes has led to significant innovations in low pressure molding machines. In recent years, these machines have gained traction in various sectors due to their ability to deliver high-quality molded products while minimizing material waste and energy consumption. Experts predict that 2025 will see remarkable trends in this field, driven by advancements in technology and an increasing focus on sustainability.

Dr. Emily Thompson, a leading expert in the low pressure molding industry, emphasizes the importance of innovation in this sector, stating, "The future of low pressure molding machines lies in their adaptability and efficiency, allowing manufacturers to meet the growing demand for customized solutions." Her insights underscore the transformative role that low pressure molding machines will play in shaping manufacturing practices, as companies look to enhance productivity and reduce their environmental footprint.

In this comprehensive overview, we will explore the top trends and innovations in low pressure molding machines anticipated for 2025, examining how these advancements are set to redefine manufacturing processes across diverse industries. By understanding these developments, businesses can better prepare for the future and leverage the capabilities of low pressure molding machines to achieve greater operational success.

Low pressure molding machines are increasingly becoming essential tools in various manufacturing sectors, thanks to their ability to create durable and efficient products with minimal waste. These machines operate at lower temperatures compared to traditional molding processes, which reduces the risk of damaging sensitive components and allows for the encapsulation of delicate electronics. This makes them particularly suitable for applications in the automotive, aerospace, and medical device industries, where precision and protection are paramount.

The versatility of low pressure molding machines enables them to handle a wide range of materials, including thermoplastics and elastomers. This adaptability facilitates the production of complex shapes and designs that can meet intricate industry requirements. Additionally, low pressure molding provides a reliable method for integrating components and providing insulation, resulting in products that not only meet functional standards but also excel in thermal and chemical resistance. As industries continue to evolve, the use of low pressure molding is expected to expand, fostering innovation and driving new applications across various fields.

The low pressure molding industry is poised for significant transformation in 2025, driven by several key innovations that enhance efficiency and performance. One notable trend is the integration of advanced materials, which allows for greater flexibility in design and improved durability of molded components. These materials not only reduce weight but also enhance thermal and chemical resistance, making them ideal for various applications across diverse sectors.

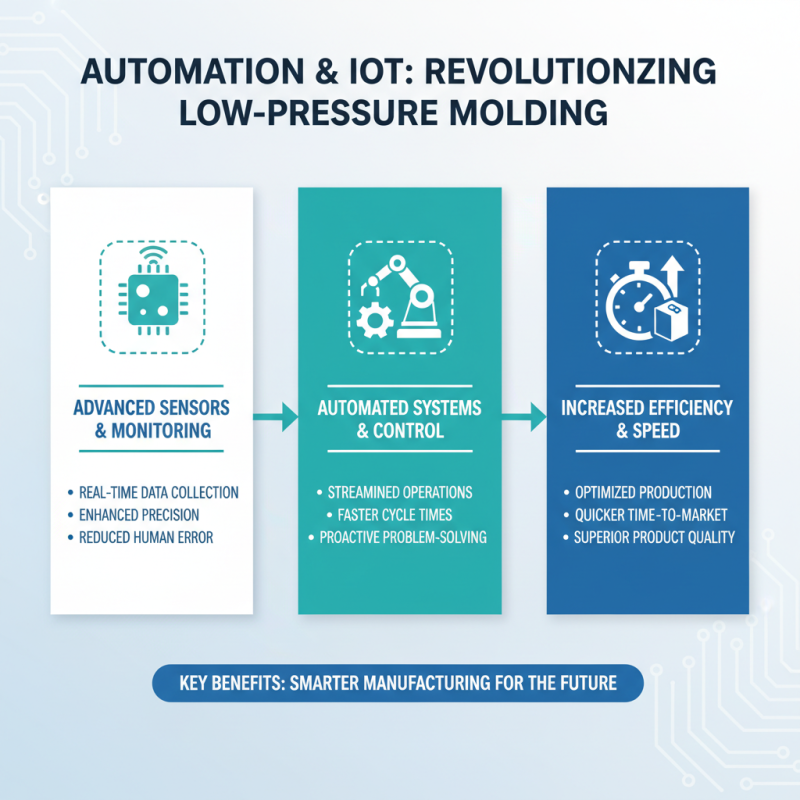

Another critical advancement is the incorporation of smarter automation technologies. The rise of Industry 4.0 has paved the way for low pressure molding machines equipped with intelligent sensors and real-time data analytics. These features enable manufacturers to optimize production processes, monitor machine performance, and reduce downtime, ultimately leading to higher productivity and lower operational costs. As the industry progresses, these innovations are expected to redefine the landscape of low pressure molding, ensuring that manufacturers remain competitive and responsive to market demands.

The landscape of low pressure molding is evolving, with significant trends emerging in the materials used for manufacturing. As industries strive for enhanced efficiency and sustainability, thermoplastic materials are gaining traction. According to a recent report by Research and Markets, the global low pressure molding market is expected to reach a valuation of over $1 billion by 2025, driven mainly by advancements in material technologies. These thermoplastics not only offer superior performance in terms of durability and flexibility but also enable recyclability, aligning with the increasing demand for environmentally responsible manufacturing processes.

Another key trend involves the integration of advanced composites in low pressure molding applications. Materials such as polycarbonate and polypropylene are being utilized for their lightweight properties and impact resistance, making them ideal for various sectors, including automotive and electronics. A study by MarketsandMarkets highlighted that the automotive segment alone is projected to witness a growth rate of around 6.5% CAGR through 2025, influenced by the continuous innovation in molding materials. This dynamic shift not only enhances product longevity but also contributes to overall cost savings and efficiency in production processes, reinforcing the strategic importance of material selection in low pressure molding operations.

The integration of automation and the Internet of Things (IoT) is significantly transforming low pressure molding processes, leading to increased efficiency and precision. As manufacturers embrace automated systems, low pressure molding machines are now equipped with advanced sensors and monitoring capabilities. These technologies enable real-time data collection and analysis, allowing operators to make informed decisions and swiftly address production challenges. Automation not only streamlines operations, reducing human error, but also enhances the overall speed of the molding process, resulting in faster time-to-market for products.

Moreover, IoT connectivity facilitates seamless communication between machines and management systems. This connectivity allows for remote monitoring and control, enabling manufacturers to optimize their workflows and maintenance schedules. Predictive analytics, powered by IoT data, helps in identifying potential issues before they become critical, minimizing downtime and ensuring high-quality output. As these trends continue to evolve, low pressure molding processes will increasingly rely on smart technologies, driving innovations that will define the manufacturing landscape in 2025 and beyond.

As the landscape of low pressure molding technologies evolves, several challenges and opportunities are emerging that will shape their future. One significant challenge is the need for improved material compatibility. As industries demand more versatile solutions, manufacturers must invest in research and development to create materials that can withstand diverse applications while maintaining performance integrity. This not only requires advancements in material sciences but also collaboration between different sectors to ensure compatibility and efficiency in production.

On the other hand, the rise of automation and smart manufacturing processes presents a substantial opportunity for the low pressure molding sector. Integrating advanced technologies such as IoT and machine learning can optimize production workflows, enhance precision, and reduce waste. These innovations can lead to faster turnaround times and lower operational costs, positioning companies to meet increasing consumer demands. Furthermore, the push for sustainable practices offers a unique opportunity to revolutionize low pressure molding processes by incorporating eco-friendly materials and energy-efficient systems, attracting environmentally-conscious markets and ensuring long-term viability.