In 2023, the demand for effective mold solutions has reached unprecedented levels, driven by growing consumer expectations and stricter industry regulations. According to a recent report by the Global Mold and Die Market Research, the industry is projected to exceed $10 billion by the end of the year, reflecting a significant shift towards innovative manufacturing technologies that prioritize efficiency and sustainability.

This comprehensive guide delves into the transformative mold solutions reshaping industry standards, highlighting advancements such as 3D printing and eco-friendly materials that enhance production processes. As manufacturers strive to reduce waste and optimize performance, understanding the latest trends in mold technology is crucial for maintaining a competitive advantage in this rapidly evolving landscape.

Join us as we explore the key strategies and innovations that are driving the future of mold solutions in 2023 and beyond.

In 2023, the landscape of mold solutions is undergoing significant transformation, driven by advancements in technology and evolving industry standards. According to a report by Smithers Pira, the global market for mold remediation services is projected to reach $5.5 billion by the end of the year, reflecting a compound annual growth rate (CAGR) of 7.4%. This growth is fueled by increasing awareness of health risks associated with mold exposure, necessitating more effective and innovative solutions.

Emerging techniques and materials are redefining traditional approaches to mold management. For instance, the introduction of biocide-resistant coatings and environmentally friendly remediation products not only enhances efficacy but also aligns with global sustainability goals. A recent study from MarketsandMarkets indicates that the demand for green mold solutions is expected to grow by 10% annually, highlighting a shift in consumer preference towards safer, more sustainable options. These innovations are not only transforming the way industries address mold issues but are also setting new benchmarks for compliance and safety standards across various sectors, including construction, healthcare, and food production.

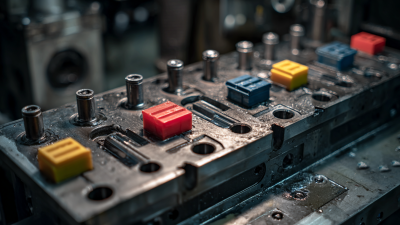

Innovative techniques for efficient mold design and production are taking center stage in 2023, reshaping how industries approach manufacturing processes. With the integration of advanced technologies such as 3D printing and computer-aided design (CAD), engineers are now able to create complex mold geometries that were previously unattainable. These methods not only reduce lead times but also minimize material waste, leading to a more sustainable manufacturing cycle. By leveraging rapid prototyping techniques, designers can iterate on their mold designs quickly, ensuring that final products meet stringent performance criteria while reducing costs.

Furthermore, the implementation of smart technologies like IoT sensors and machine learning algorithms in mold production is revolutionizing maintenance and performance monitoring. These innovations allow for real-time data collection and analysis, enabling manufacturers to predict mold wear and tear, thereby optimizing maintenance schedules and reducing downtime. As industries continue to embrace these cutting-edge solutions, the landscape of mold design and production is set to evolve, driving efficiency and adaptability in an ever-demanding market.

In 2023, the mold manufacturing industry is witnessing a significant transformation driven by the implementation of sustainable practices. According to a recent report by the International Plastics Association, sustainable mold manufacturing techniques can reduce production waste by up to 30%, significantly lowering the environmental impact. This shift not only aligns with global sustainability goals but also enhances operational efficiency. By adopting methodologies such as additive manufacturing and incorporating recycled materials, companies can produce molds that are not only environmentally friendly but also cost-effective.

Moreover, the integration of innovative technologies like Industry 4.0 is further revolutionizing mold production. A study published by the Sustainable Manufacturing Institute indicates that organizations utilizing smart manufacturing practices have seen productivity increases of approximately 15% while simultaneously reducing energy consumption by 25%. These advancements showcase how the collaboration between technology and sustainability can lead to superior mold designs that meet evolving industry standards. Embracing these innovative mold solutions not only benefits businesses but also contributes positively to the broader ecological footprint.

This chart illustrates the percentage adoption of innovative and sustainable practices in mold manufacturing across various sectors in 2023. The data reflects the trend towards eco-friendly solutions in the industry.

In 2023, the mold manufacturing industry is witnessing a significant transformation driven by the adaptation of new technologies. Cutting-edge advancements such as 3D printing and smart manufacturing are enhancing mold performance and productivity. A recent study by Grand View Research estimated that the global mold market will reach $12.2 billion by 2027, fueled by these technological innovations. These trends highlight the industry's shift towards more efficient production methods and customized solutions that meet the diverse needs of various sectors.

The integration of artificial intelligence (AI) and machine learning into mold design and production processes is another key development. According to a report from MarketsandMarkets, the AI in manufacturing market is projected to grow from $1.41 billion in 2020 to $13.24 billion by 2028, indicating a robust adoption of these technologies across industries. Implementing AI allows manufacturers to optimize designs, predict maintenance issues, and enhance overall mold quality, significantly reducing downtime and production costs. As companies strive for operational excellence, these advanced technologies are not just improving mold performance; they are setting new industry standards for efficiency and sustainability in 2023.

In 2023, the mold industry is undergoing a significant transformation, driven by innovative solutions and digitalization efforts. A notable case is the transition of a "black hand factory" in Dongguan into a "black lamp factory," symbolizing the shift towards enhanced digital manufacturing practices. This change is part of a broader trend, as over 9,000 regulated industrial enterprises in Dongguan have embarked on digital transformation initiatives. Despite these advancements, there remains substantial room for growth among the 210,000 industrial enterprises in the city, highlighting the potential for further innovation in mold solutions.

Additionally, the inaugural Digital Transformation Innovation Development Conference organized by the China Academy of Information and Communications Technology marked a milestone in sharing successful transformation case studies across various industries. This event showcased exemplary digital practices and provided a platform for industry leaders to share insights on high-quality digital transformation. With the convergence of technology and innovative mold solutions, the mold industry is poised to redefine its standards in the coming years, reflecting the importance of embracing digital advancements to improve operational efficiency and product quality.