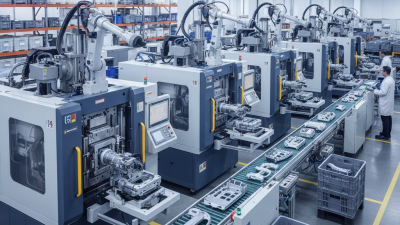

Injection molding is a widely used manufacturing process. It creates parts by injecting molten materials into a mold. This method is popular in industries like automotive, consumer goods, and electronics. Products range from tiny components to large housings.

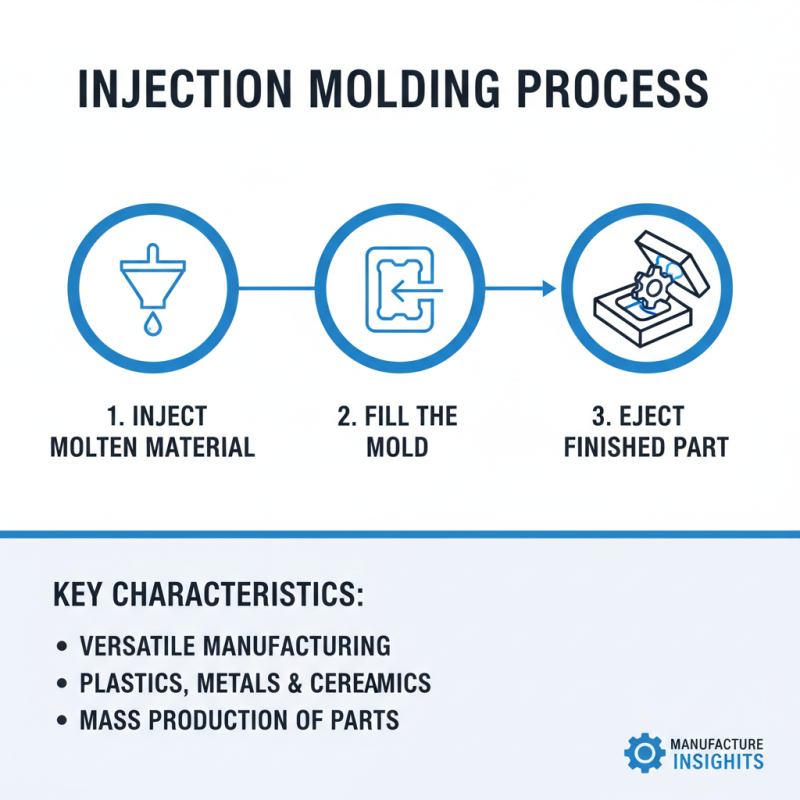

In injection molding, precision is crucial. The process begins with plastic pellets that are heated until they melt. Then, this molten plastic is injected under pressure into a mold cavity. Once cooled, the mold opens, and the new part is ejected. Attention to detail in mold design affects the final product's quality. Variations in temperature and pressure can lead to defects, reminding us that perfection requires constant monitoring.

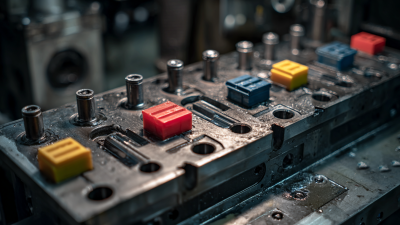

Despite its advantages, injection molding isn't flawless. Complex geometries can challenge the design. Sometimes molds wear out, leading to inconsistencies in production. Therefore, effective maintenance and design adjustments are necessary for optimal performance. Understanding injection molding involves recognizing these intricacies and embracing the learning curve inherent in the process.

Injection molding is a widely used manufacturing process for creating plastic parts. By injecting molten material into a mold, manufacturers can produce complex shapes with high precision. According to industry reports, the injection molding market is projected to grow to $300 billion by 2024. This growth reflects diverse applications across various sectors.

The automotive industry is a major user of injection molding. It utilizes this method to create components like dashboards and paneling. In 2022, injection-molded parts contributed roughly 30% of the total automotive plastic consumption. The efficiency of the process allows for rapid production, essential in a fast-paced market.

Consumer products also heavily rely on injection molding. Items such as containers, toys, and home appliances are all manufactured using this method. However, environmental concerns arise with the use of plastics. The sector must reflect on recycling practices. Efficient waste management could enhance overall sustainability. Despite technological advancements, the challenge remains to balance production with ecological responsibility.

| Dimension | Details |

|---|---|

| Process Type | Thermal Process |

| Materials Used | Plastics, Metals, Ceramics |

| Common Applications | Automotive parts, Consumer electronics, Medical devices |

| Advantages | High efficiency, Low waste, Complex shapes |

| Disadvantages | High initial cost, Limited material options |

| Cycle Time | 15-60 seconds |

| Machine Types | Hydraulic, Electric, Hybrid |

Injection molding is a widely used manufacturing process. It creates parts by injecting molten material into a mold. This process is essential in producing plastic items and can also work with metals and ceramics.

The steps in injection molding begin with material selection. Engineers choose based on factors like durability and cost. Next, raw materials are fed into a heated barrel. Here, they melt and become a fluid. Then, this fluid is injected into a mold cavity. Pressures can exceed 30,000 PSI, emphasizing the strength often needed in industrial applications.

Cooling follows. The material solidifies inside the mold. Cooling times vary, often taking several seconds to a few minutes. Once the part cools, it is ejected. Manufacturers report that the cycle can take less than a minute for simple shapes, while complex designs may require longer. Data shows that approximately 30% of total production time is for cooling. This reflects the importance of optimizing cycles to enhance efficiency.

However, the process is not without challenges. Mold design errors can lead to defects. These can include warping or incomplete filling. Such issues require careful attention throughout production. Many experts suggest continuous testing and improvement to refine the process.

Injection molding relies heavily on material selection. The choice of plastic has a significant impact on the final product’s quality. Common materials include thermoplastics like ABS, polycarbonate, and nylon. Each of these materials possesses unique properties. For instance, ABS is known for its toughness and impact resistance. In contrast, polycarbonate offers excellent transparency and heat resistance.

According to industry reports, thermoplastics represent over 90% of materials used in injections. This dominance is due to their versatility and reusability. For example, nylon is often favored for its durability and flexibility. However, additives can alter material properties. This means careful consideration is needed when selecting materials for specific applications.

Despite advancements, challenges persist. Some materials can degrade or lose properties under extreme conditions. This can lead to unexpected failures in final products. Moreover, variations in material quality can affect consistency. These factors highlight the importance of thorough testing and quality assurance in the injection molding process. Proper material selection is critical to achieve desired outcomes and minimize waste.

Injection molding is a widely used manufacturing process. It has its own set of advantages and disadvantages. Understanding these can help in making informed decisions.

One key advantage is efficiency. Injection molding can produce large quantities of parts quickly. This reduces labor costs and increases production speed. The precision of the process results in tightly controlled specifications. However, the initial setup costs can be high. Equipment and mold creation require significant investment. For small production runs, this may not be cost-effective.

Injection molding is a widely used manufacturing process, especially in various industries. It allows for the mass production of plastic products with high precision. Common industries benefiting from this technique include automotive, consumer goods, and healthcare.

In the automotive sector, many parts such as dashboard components and interior fittings are created using injection molding. These parts must be durable and light, and injection molding meets these requirements well. In consumer goods, items like kitchenware and toys are produced this way. However, not all designs translate perfectly. Sometimes, molds can wear down, leading to imperfections.

Healthcare is another significant area. Many medical devices and containers are produced through this process. Accuracy is crucial, as even small errors can impact safety. However, there are challenges. For instance, ensuring the consistency of materials can be tricky. Some products may not meet strict requirements, leading to waste. Despite these challenges, injection molding remains vital across these industries. It combines efficiency and versatility, although it requires constant attention to detail.