The injection molding machine is a pivotal technology in modern manufacturing, playing a crucial role in the production of intricate plastic components that power countless industries. According to a report by Research and Markets, the global injection molding machine market was valued at approximately $16.77 billion in 2020 and is projected to reach $26.5 billion by 2026, growing at a CAGR of 8.5%. This impressive growth underscores the increasing demand for high-quality, efficient production methods that injection molding uniquely provides.

For beginners looking to navigate this complex field, understanding the principles and mechanics of injection molding machines is essential. This comprehensive guide will demystify the operation, types, and applications of these remarkable machines, equipping newcomers with the knowledge necessary to thrive in the rapidly evolving landscape of manufacturing technology.

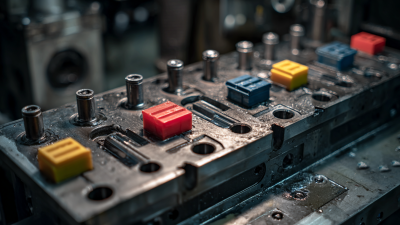

Injection molding machines are essential in modern manufacturing, particularly in the production of plastic components. Understanding the key components of these machines is vital for beginners looking to enter this field. The primary components include the injection unit, clamping unit, and control system. The injection unit is responsible for melting the plastic and injecting it into the mold, while the clamping unit secures the mold during the injection process. The control system manages the entire operation, ensuring precision and efficiency.

Recent market trends indicate significant growth in the injection molding industry. For instance, the global micro injection molding machine market is projected to expand from $551.3 million in 2025 to $759.2 million by 2032. This growth is driven by rising demand for lightweight components in sectors such as automotive and packaging. Additionally, the Indian injection molding machines market is expected to reach a valuation of $830.9 million by 2025, highlighting the increasing adoption of these technologies in emerging markets. Understanding these components and market dynamics will empower beginners to navigate the complexities of injection molding effectively.

| Component | Description | Function |

|---|---|---|

| Injection Unit | This unit is responsible for melting and injecting the plastic into the mold. | To deliver a precise volume of molten plastic into the mold cavity. |

| Clamping Unit | This component holds the two halves of the mold together during the injection process. | To maintain mold alignment and withstand the injection pressure. |

| Mold | The shaped cavity that forms the final part during cooling. | To create the desired shape of the injected plastic part. |

| Material Hopper | A container that holds the raw plastic pellets before they are fed into the injection unit. | To provide a steady supply of material for the injection process. |

| Heating and Cooling Systems | Systems used to manage the temperature of the material and mold. | To ensure the material is at the proper temperature for injection and to cool the mold after filling. |

The injection molding process is a fascinating and intricate method used for creating various plastic products. It begins with the heating of plastic pellets until they melt into a viscous state. This molten plastic is then injected into a pre-designed mold under high pressure. This crucial step ensures that the plastic fills every intricate detail of the mold, allowing for the production of complex shapes and designs. As the material cools and solidifies within the mold, it takes on the desired form, resulting in a finished product ready for further processing or assembly.

Understanding the injection molding process involves a step-by-step breakdown that covers essential phases, from material selection to cooling and ejection. The emphasis on precise parameters, such as temperature control and injection speed, is vital for achieving high-quality results. Moreover, advancements in technologies, including the integration of generative AI, can enhance production efficiency and product design in this field. By analyzing data and optimizing processes, manufacturers can innovate continuously, ultimately leading to improved operational effectiveness and reduced waste in the injection molding industry.

When selecting the right injection molding machine for your production needs, understanding the specifications and capabilities of various machines is crucial. According to a report by Research and Markets, the global market for injection molding machines is expected to grow at a CAGR of 4.8%, reaching a value of $11.9 billion by 2025. This growth is driven by increasing demands in automotive, medical, and consumer goods sectors, necessitating a careful evaluation of machine type and configuration.

Key factors to consider include clamping force, shot size, and cycle times, which vary by machine type. For example, electric injection molding machines provide precision and energy efficiency, making them suitable for intricate designs and smaller production runs. In contrast, hydraulic machines are often favored for larger, high-volume applications due to their robust clamping force and durability. According to the Association for Manufacturing Technology, a well-chosen injection molding machine can improve production efficiency by up to 30%, underlining the importance of aligning machine capabilities with operational objectives.

Injection molding is a highly efficient manufacturing process, but it comes with its own set of challenges. Operators often face common issues such as production inefficiencies, unexpected downtime, and increased scrap rates. Understanding these challenges and their solutions is critical to optimizing the injection molding process.

Injection molding is a highly efficient manufacturing process, but it comes with its own set of challenges. Operators often face common issues such as production inefficiencies, unexpected downtime, and increased scrap rates. Understanding these challenges and their solutions is critical to optimizing the injection molding process.

One of the top issues in injection molding is inconsistent pressure during the molding process, which can lead to defects like sink marks and warpage. To troubleshoot these problems, ensure that the machine parameters are set correctly and regularly maintenance is performed to keep the machinery in optimal condition. Additionally, using advanced software tools can help predict issues related to injection pressure and enhance mold design.

Tips: Regularly check and calibrate equipment settings to maintain consistent product quality. Consider investing in technology solutions that provide real-time monitoring and predictive analytics, helping operators identify issues before they escalate. Lastly, continuous training of personnel ensures that the team is equipped to handle minor faults and can troubleshoot effectively when problems arise, reducing dependency on highly trained personnel.

Maintaining your injection molding machine is crucial for optimal performance and longevity. Regular maintenance not only prevents unexpected breakdowns but also enhances the quality of your molded products. Keeping the machine clean and lubricated goes a long way in ensuring smooth operation. Additionally, routinely checking key components like the hydraulic system and the nozzles can help identify potential issues before they escalate.

Tips: Implement a daily checklist for machine inspection to streamline your maintenance routine. Ensure that all moving parts are adequately lubricated, and monitor the temperature settings to avoid overheating. Consider investing in advanced control systems, such as deep reinforcement learning-enhanced PID controls, to improve accuracy in your machine's performance.

Another crucial aspect of maintenance is keeping abreast of the latest advancements in technology. For instance, companies are exploring innovative recycling technologies to improve sustainability and efficiency in the injection molding process. Understanding and integrating such technologies into your operations can lead to significant competitive advantages.

Tips: Stay informed about new developments in injection molding, and assess how they could be integrated into your current setup. Attend workshops and trade shows to learn from industry leaders about best practices in machine maintenance.