Injection molding is a pivotal manufacturing process that revolutionizes the way products are made, particularly in the realm of plastics. At the heart of this process lies the injection molding equipment, which is essential for transforming raw materials into complex shapes with precision and efficiency. For beginners, understanding the fundamental components and functionalities of injection molding equipment can be overwhelming, yet it is crucial for anyone looking to venture into the world of manufacturing or product design.

This comprehensive guide aims to demystify injection molding equipment, breaking down its various types, components, and operational processes. From understanding the intricacies of the injection machine itself to exploring auxiliary equipment that enhances production, this resource provides a clear pathway for newcomers. Through this introduction, readers will gain valuable insights into why injection molding is favored in many industries, the significance of selecting the right equipment, and how it can impact the overall quality and cost-effectiveness of production. Whether you are considering starting a manufacturing venture or simply interested in learning about the injection molding process, this guide will equip you with the knowledge necessary to navigate this essential field successfully.

Injection molding equipment is an essential part of the manufacturing process for a variety of industries, including automotive, consumer goods, and medical devices. At its core, injection molding involves the process of melting plastic or other materials and injecting them into a mold to produce specific shapes and parts. According to a report by MarketsandMarkets, the global injection molding machine market is projected to reach $12.3 billion by 2026, reflecting a compound annual growth rate (CAGR) of 5.5% from 2021. This growth can be attributed to the increasing demand for efficient production processes that can handle complex designs.

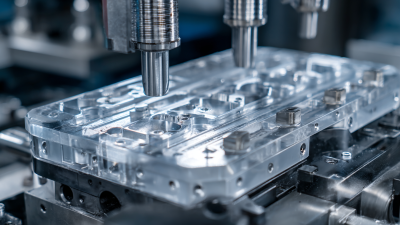

The equipment itself consists of several key components, including the injection unit, clamping unit, and control system. The injection unit is responsible for melting the material and injecting it into the mold, while the clamping unit holds the mold in place during the injection process. Advanced technologies in injection molding machines, such as servo-driven systems, are enhancing energy efficiency and reducing cycle times, leading to significant cost savings for manufacturers. Experts from industry sources suggest that modern injection molding machines can achieve production cycles as short as 10 seconds, depending on the part design and material used. This efficiency is critical in meeting the growing demands for rapid prototyping and mass production in a fast-paced market.

Injection molding machines are sophisticated pieces of equipment designed for creating a wide array of plastic products. Understanding the key components of these machines is essential for anyone venturing into the world of injection molding. At the heart of the machine is the injection unit, which is responsible for melting the plastic material and injecting it into a mold. This unit typically consists of a hopper, where raw plastic is fed, a barrel that heats and liquefies the plastic, and a screw that aids in mixing and injecting the molten plastic into the mold.

Another critical component is the clamping unit, which holds the mold securely during the injection process. This unit provides the necessary force to keep the mold closed against the high pressure of the injected plastic. Clamping units can vary widely in size and function, often supported by a hydraulic or mechanical system that ensures precision and efficiency. Additionally, many machines incorporate a cooling system to manage the temperature of the mold, allowing the injected plastic to solidify quickly and ensuring a smooth and efficient production cycle. Understanding these components provides insight into the operational efficiency and effectiveness of injection molding processes, crucial for any beginner in the field.

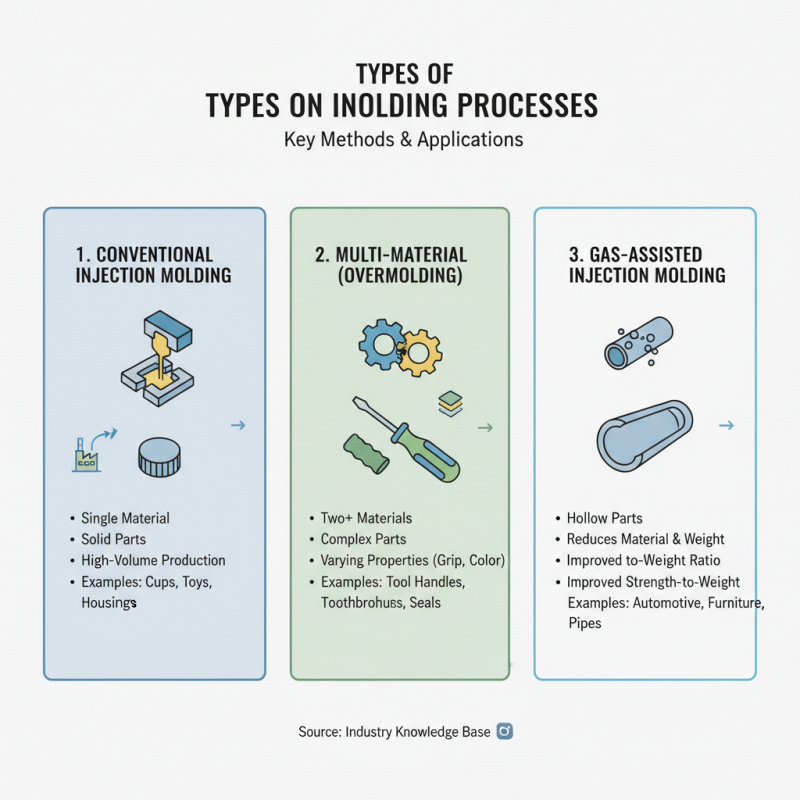

Injection molding is a popular manufacturing process used to create a wide variety of products, and understanding its different types is crucial for anyone entering this field. The primary methods of injection molding include conventional injection molding, multi-material (or overmolding), and gas-assisted injection molding. Conventional injection molding involves injecting melted plastic into a mold to create a solid part, making it ideal for high-volume production. Multi-material injection molding allows for the use of two or more materials to create complex parts with different properties, such as soft grips or color combinations. Gas-assisted injection molding introduces gas into the mold to create hollow parts, reducing material use and weight.

When diving into injection molding processes, it's essential to pay attention to several key factors that can impact the final product. One tip is to ensure proper mold design to avoid defects like warping or incomplete filling. Additionally, keep in mind that material selection plays a significant role in the performance of the final item—different plastics can provide varying degrees of strength, flexibility, and resistance to environmental factors.

Another useful tip for beginners is to collaborate closely with your mold maker. A good partnership can help identify potential issues early in the design phase, saving time and costs down the road. Investing time in understanding these molds and processes can lead to smoother production and a more successful end product.

Injection molding is a versatile manufacturing process commonly used across various industries due to its efficiency and ability to produce complex shapes at scale. One of the primary applications of injection molding can be found in the automotive industry, where it is used to create components like dashboards, door panels, and connectors.

These parts require high precision and durability, which injection molding readily provides. Similarly, in the consumer goods sector, items such as household appliances, toys, and packaging are often produced using this method, allowing for quick production cycles and consistent quality.

Tips: When considering injection molding for your next project, keep in mind the importance of material selection. The choice of plastic resin can significantly impact the final product’s strength, flexibility, and overall appearance.

Another vital application area of injection molding is in the medical field. Here, it is employed to manufacture sterile components like syringe bodies, IV bags, and other intricate medical devices. The high level of precision that injection molding offers is crucial in this sector, where even the smallest imperfections can have significant implications on safety and efficacy.

Tips: For those new to injection molding, it’s essential to collaborate closely with engineers and designers early in the development process. Proper planning can optimize part design for manufacturability, ensuring smoother production and minimizing costs.

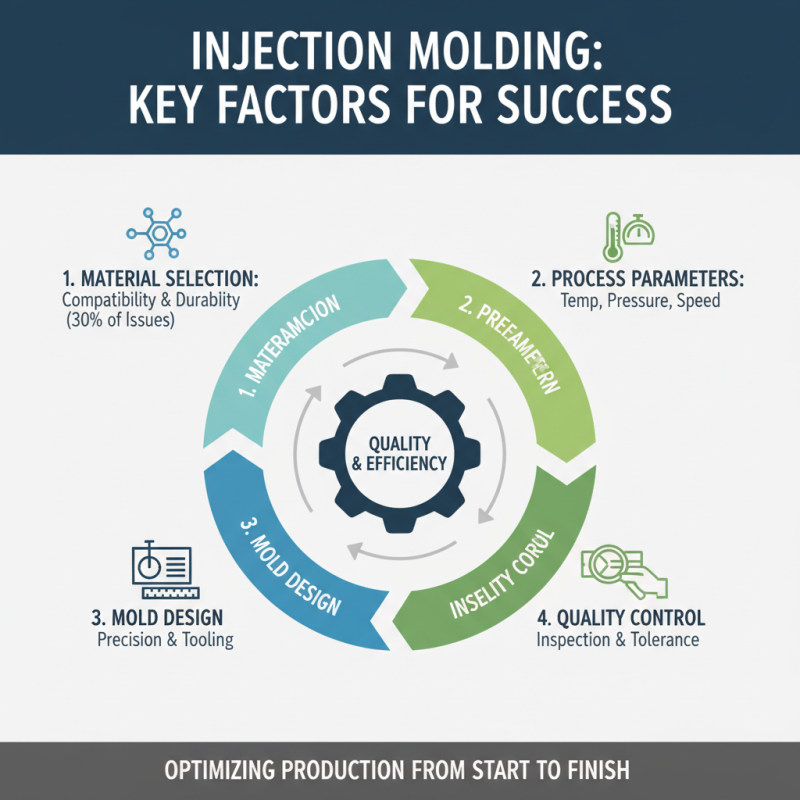

Injection molding is a widely used manufacturing process for producing parts and products with precise specifications. Several key factors influence the success of injection molding operations, ensuring quality, efficiency, and cost-effectiveness. One crucial aspect is the selection of the appropriate material. According to industry reports, more than 30% of production issues can be traced back to material choice. Materials should not only fit the application but also be compatible with the injection molding process to prevent defects and enhance durability.

Another significant factor is machine parameters. The settings for temperature, pressure, and injection speed can make or break a production run. Industry standards indicate that improperly calibrated machines can lead to defects ranging from warping to incomplete parts, often resulting in a waste rate of up to 20%. Therefore, it is essential to conduct regular maintenance and calibration checks on the injection molding equipment to maintain optimal performance.

**Tips:** When selecting materials, consider their thermal properties and compatibility with the design to avoid issues down the line. Additionally, stay updated on machine calibration best practices to enhance the efficiency of your injection molding process. Regular training for operators can also ensure they are aware of potential pitfalls and best practices in setting machine parameters. This proactive approach can significantly reduce waste and improve overall production quality.