In the contemporary landscape of manufacturing, the significance of the injection machine cannot be overstated. According to the latest report from the Research Institute of Plastic Engineering, the global market for injection molding machines is projected to grow at a compound annual growth rate (CAGR) of 5.8% from 2021 to 2028, driven by increasing demand from various sectors including automotive, consumer goods, and healthcare. Injection machines are pivotal in enabling manufacturers to achieve precision and efficiency, producing high-quality parts with minimal waste and reduced cycle times. As industries become more competitive, the role of injection molding technology is evolving, integrating advanced automation and IoT capabilities that not only enhance production efficiency but also contribute to sustainability efforts. This introduction delves into the multifaceted functions of injection machines within modern manufacturing processes and explores their impact on the industry's future trajectory.

In the contemporary landscape of manufacturing, the significance of the injection machine cannot be overstated. According to the latest report from the Research Institute of Plastic Engineering, the global market for injection molding machines is projected to grow at a compound annual growth rate (CAGR) of 5.8% from 2021 to 2028, driven by increasing demand from various sectors including automotive, consumer goods, and healthcare. Injection machines are pivotal in enabling manufacturers to achieve precision and efficiency, producing high-quality parts with minimal waste and reduced cycle times. As industries become more competitive, the role of injection molding technology is evolving, integrating advanced automation and IoT capabilities that not only enhance production efficiency but also contribute to sustainability efforts. This introduction delves into the multifaceted functions of injection machines within modern manufacturing processes and explores their impact on the industry's future trajectory.

Injection molding has become a cornerstone of modern manufacturing, playing a crucial role in the production of a vast array of products, from automotive components to consumer goods. As the manufacturing landscape evolves amid growing environmental concerns and the push for sustainability, low-pressure injection molding emerges as a promising innovation. This technique not only minimizes material waste but also reduces energy consumption, making it an attractive solution for companies striving for eco-friendliness in their operations.

Injection molding has become a cornerstone of modern manufacturing, playing a crucial role in the production of a vast array of products, from automotive components to consumer goods. As the manufacturing landscape evolves amid growing environmental concerns and the push for sustainability, low-pressure injection molding emerges as a promising innovation. This technique not only minimizes material waste but also reduces energy consumption, making it an attractive solution for companies striving for eco-friendliness in their operations.

In the context of increasing digitization in manufacturing, investing in state-of-the-art injection molding technology has never been more critical. This includes the integration of all-electric machines and robotic systems, which enhance precision and efficiency. Furthermore, specialized training for operators in the plastics industry ensures that the workforce is equipped with the necessary skills to meet modern challenges. As industry leaders recognize the importance of qualitative advancements in production methods, the role of injection molding in contributing to a competitive and sustainable manufacturing environment continues to grow.

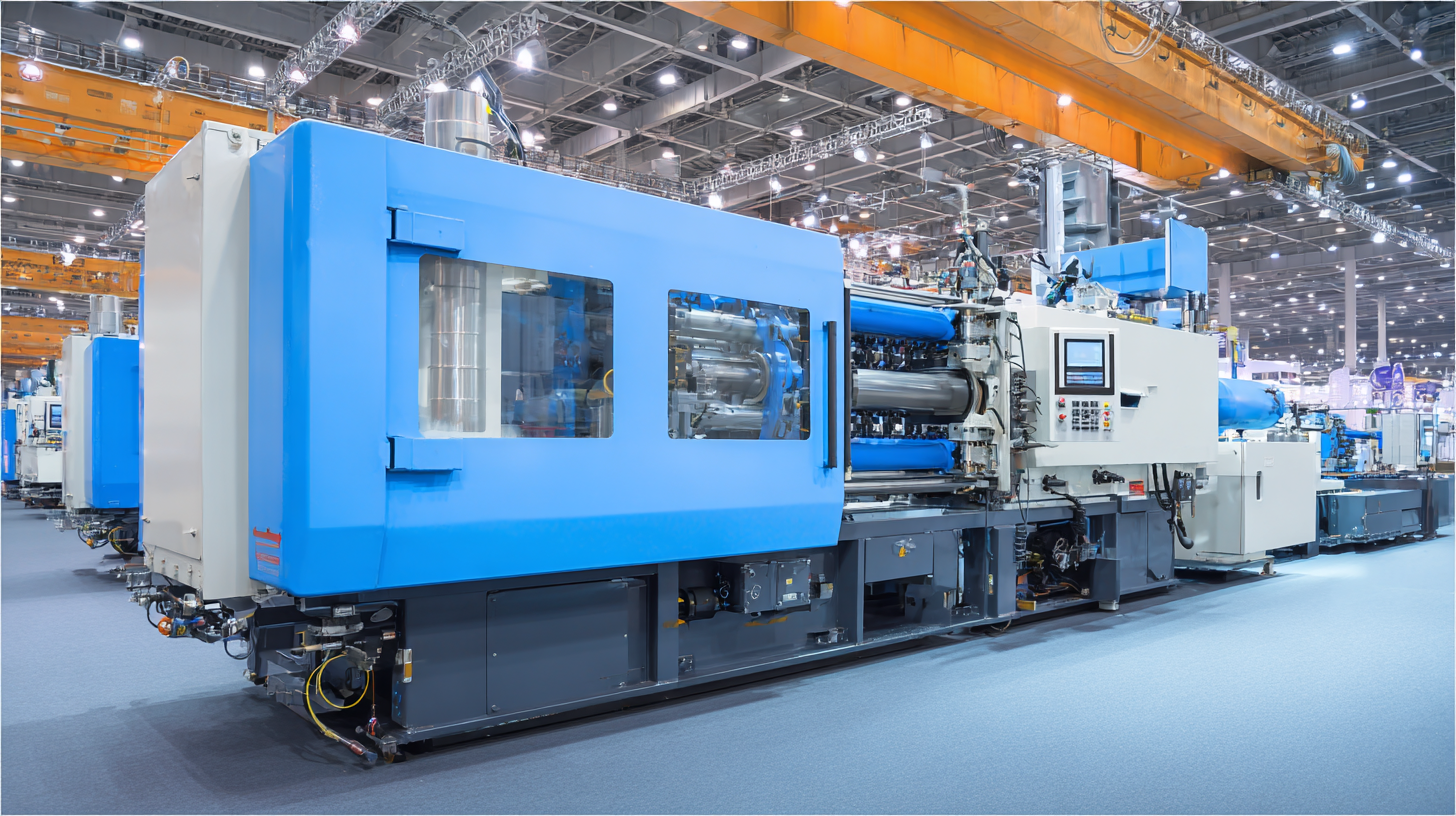

Injection machines play a pivotal role in modern manufacturing, particularly in the production of plastic components. These advanced machines operate through a process that involves melting plastic pellets and injecting the molten material into a mold to create a desired shape. According to a report by MarketsandMarkets, the global injection molding machine market size is expected to grow from $16.1 billion in 2020 to $23.5 billion by 2025, significantly highlighting their importance in various industries, including automotive, consumer goods, and electronics.

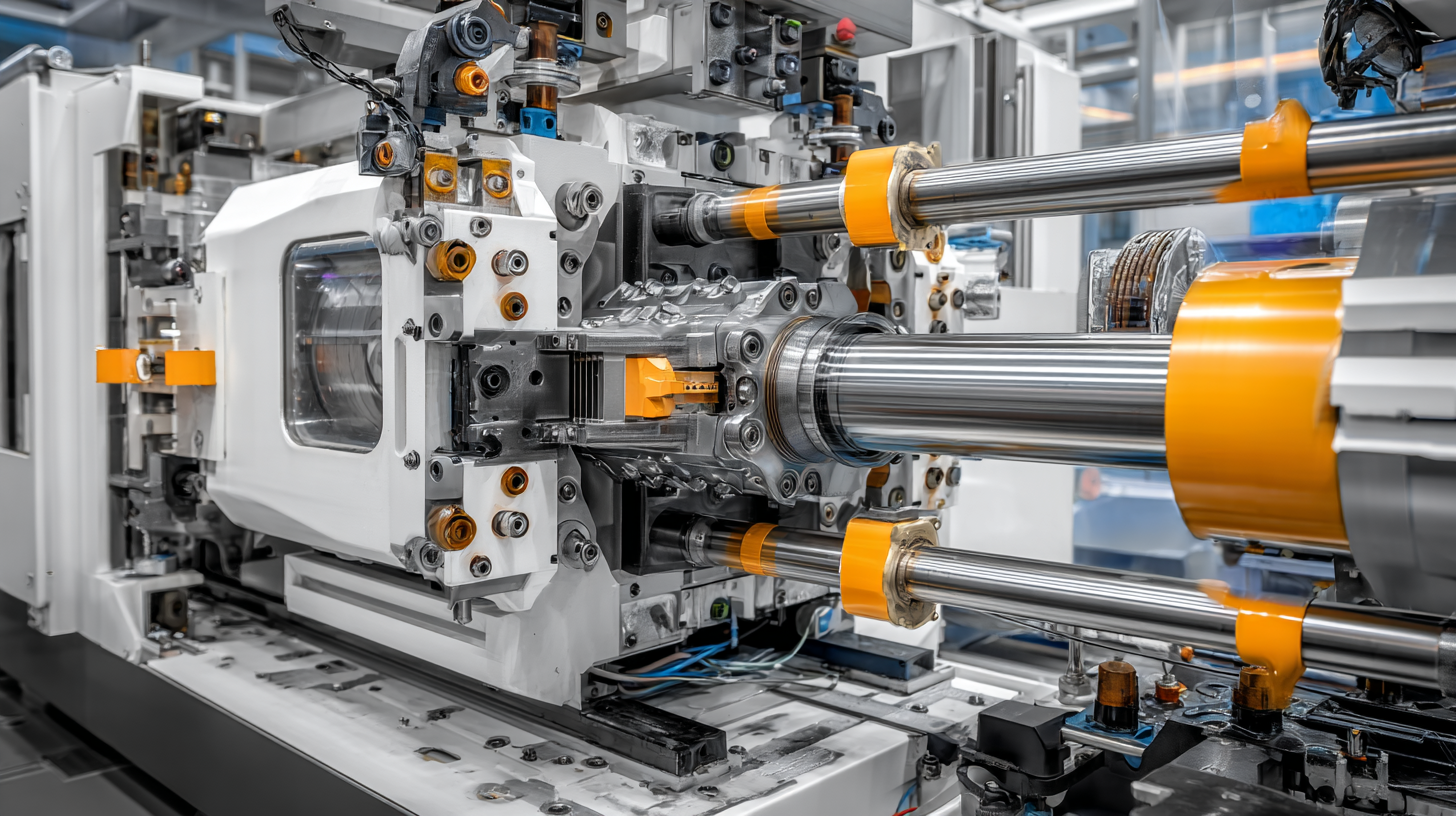

Key components of injection machines include the injection unit, clamping unit, and control system. The injection unit is responsible for melting and injecting the plastic into the mold, while the clamping unit holds the mold closed during injection and cools down the part. A study published by Grand View Research indicates that advancements in hydraulic systems and servo motor technology have improved energy efficiency in injection machines, leading to reduced operational costs by up to 30%. Furthermore, the integration of smart technologies and IoT capabilities enables real-time monitoring and predictive maintenance, enhancing production efficiency and minimizing downtime in manufacturing processes.

| Component | Functionality | Material Compatibility | Typical Use Cases |

|---|---|---|---|

| Injection Unit | Heats and injects thermoplastic material into the mold | Polyethylene, Polystyrene, Polypropylene | Packaging, Automotive Parts |

| Clamping Unit | Secures the mold during injection and cooling | Various thermosets and thermoplastics | Consumer Electronics, Medical Devices |

| Mold | Shapes the molten material into the desired product | Steel, Aluminum | Toys, Containers, Automotive Components |

| Cooling System | Regulates the temperature of the mold to solidify the injected material | Water, Oil | Appliances, Furniture Parts |

| Control System | Monitors and controls the operation of the machine | N/A | Industrial Applications, Prototyping |

Innovative advances in injection machine technology are transforming modern manufacturing processes, leading to enhanced efficiency and product quality. These machines have evolved significantly, integrating advanced materials and smart technologies. Features such as real-time monitoring systems, energy-efficient designs, and advanced control software are becoming standard, enabling manufacturers to optimize production and reduce downtime. Moreover, innovations such as multi-component injection molding and the use of biocompatible materials have opened new avenues for complex product designs.

**Tip:** Regularly update software and hardware components of your injection machines to take advantage of the latest efficiency-enhancing technologies. Staying current can significantly improve production rates and product reliability.

Furthermore, the rise of automation and robotics in injection molding facilities is streamlining operations. Automation not only increases consistency but also reduces labor costs and minimizes human error. The integration of IoT technologies allows for predictive maintenance, ensuring that machines operate smoothly with minimal interruptions. As the industry continues to embrace these innovations, manufacturers can expect to see a further reduction in cycle times and an increase in flexibility for custom production runs.

**Tip:** Consider investing in IoT-enabled machines which provide real-time analytics, allowing you to preemptively address potential operational issues before they escalate, ensuring a seamless manufacturing process.

This chart illustrates the growth in the production volume of injection machines over the years from 2018 to 2022, highlighting the increasing role of innovative injection machine technology in modern manufacturing processes.

Injection molding is a pivotal process in modern manufacturing, and maximizing efficiency in this area can lead to significant cost savings and product quality improvements. According to a report by the Plastics Industry Association, 36% of manufacturers cited equipment efficiency as a primary concern, indicating a pressing need to refine operational practices. One best practice is the regular maintenance and calibration of injection machines to ensure they operate at optimal levels, reducing downtime and waste.

Furthermore, leveraging advanced technologies such as Industry 4.0 tools can lead to substantial gains. Data analytics can help manufacturers monitor machine performance in real time, leading to responsive adjustments that minimize cycle times and enhance product consistency. A study by Deloitte highlights that manufacturers implementing smart technologies can experience up to a 25% increase in overall equipment effectiveness (OEE). Emphasizing employee training on these technologies also ensures that teams are equipped to maximize the capabilities of injection molding machines, further driving efficiency in production.

Injection machines play a vital role in modern manufacturing processes, but operators often encounter common challenges that can impede efficiency. Among the top issues are production inefficiencies, downtime, and excess scrap, which can severely affect profitability and output quality. According to recent industry reports, nearly 70% of manufacturers identify mold-related challenges as a primary cause of production slowdowns. Addressing these challenges requires proactive measures, such as implementing robust monitoring solutions and utilizing advanced technologies that facilitate tool trials and defect containment.

Injection machines play a vital role in modern manufacturing processes, but operators often encounter common challenges that can impede efficiency. Among the top issues are production inefficiencies, downtime, and excess scrap, which can severely affect profitability and output quality. According to recent industry reports, nearly 70% of manufacturers identify mold-related challenges as a primary cause of production slowdowns. Addressing these challenges requires proactive measures, such as implementing robust monitoring solutions and utilizing advanced technologies that facilitate tool trials and defect containment.

Innovations in smart manufacturing are also transforming the landscape of injection machine operations. By leveraging integrated technologies, manufacturers can enhance operational visibility and streamline production processes. For instance, recent advancements have introduced real-time monitoring solutions that not only predict potential breakdowns but also reduce overall operating costs by up to 20%. The ongoing evolution of injection molding technologies allows companies to adopt more efficient practices and ultimately position themselves to harness the economic potential of manufacturing innovations in the coming years.