Molding pressure plays a crucial role in various manufacturing processes. It directly influences the quality and precision of molded parts. In many industries, from automotive to consumer goods, the right molding pressure leads to better performance.

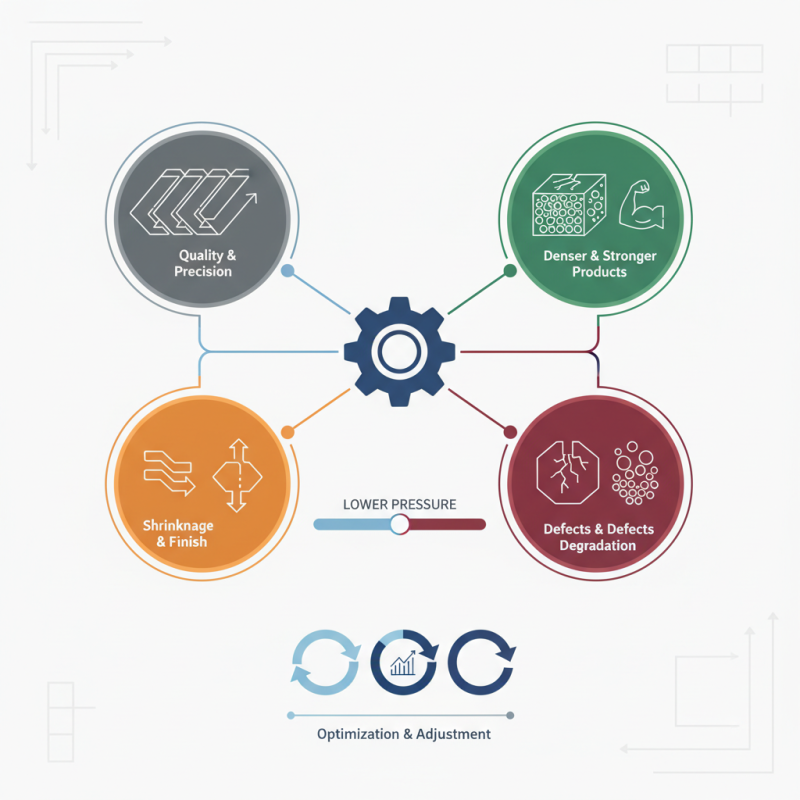

Understanding molding pressure can reveal its effects on material flow, shrinkage, and finish. Higher pressure often results in denser and stronger products, but it can also cause defects. For instance, excessive pressure may lead to material degradation or unwanted textures. Manufacturers must carefully balance these factors.

Considering the impact of molding pressure is essential for optimizing production. Each material behaves differently under pressure. Therefore, adjustments must be made for specific conditions and required outcomes. Reflection on these processes can lead to improvements.

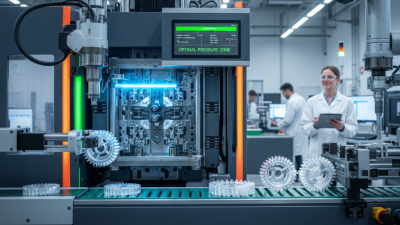

Molding pressure plays a crucial role in defining material properties and product quality.

High pressure often leads to better material compaction.

According to industry reports, optimal molding pressure can improve tensile strength by up to 25%. This enhancement helps in producing parts that withstand higher stress.

However, excessive pressure can cause issues. It might lead to internal defects or a weakened material structure. Balancing pressure is key.

Too low molding pressure could lead to voids and poor surface finish. Regular monitoring of the pressure can significantly enhance product quality.

Tips: Always calibrate your molding machines for accurate pressure readings. Small adjustments can lead to big improvements.

Experiment with different pressures to find the sweet spot for your materials. Even slight variations can affect overall performance.

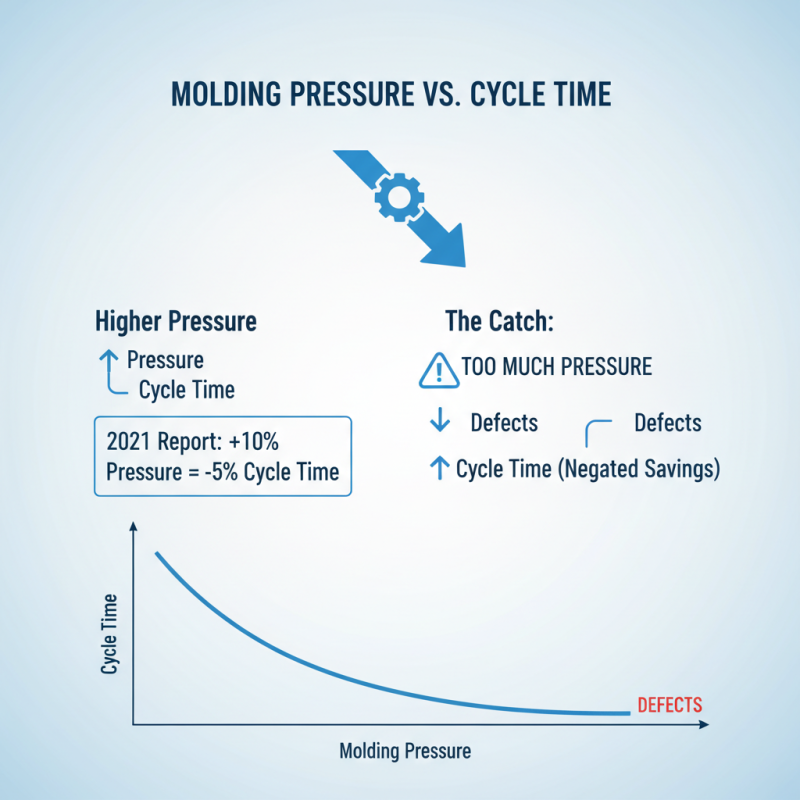

Molding pressure significantly influences cycle time in manufacturing processes. Higher pressure often leads to reduced cycle time. However, the relationship is complex and not always linear. For instance, a 2021 report indicated that increasing pressure by 10% can decrease cycle time by approximately 5%. Yet, pushing pressure too high can cause defects, which may negate time savings.

Understanding the correlation relies on several factors. Material type and mold design impact how pressure affects the cycle. Certain plastics, for example, respond well to high pressure but may warp at extreme levels. A study found that maintaining an optimal pressure setting can keep defects below 2%, while excessive pressure resulted in defect rates soaring to 15% or more. Experience has shown that manufacturers should balance pressure to achieve both quality and efficiency.

Moreover, automation in monitoring allows for adjustments during production. However, reliance on data can sometimes lead to overlooking practical nuances. Molding operators must reflect on past outcomes. Missteps often occur when pressure settings are based solely on machine parameters rather than actual performance. The challenge remains in finding the sweet spot that maximizes productivity while minimizing defects.

Molding pressure plays a crucial role in manufacturing processes. It directly affects the dimensional accuracy of molded parts. Studies show that higher molding pressure can lead to tighter tolerances. This can enhance product quality, reducing defects by up to 25%. However, it may also cause challenges.

Excessive molding pressure can result in warping and deformation. Parts may not fit together as intended. A report from the Society of Plastics Engineers noted that about 15% of defects arise from incorrect pressure settings. Proper calibration is essential. Finding the right balance is tricky.

In many cases, manufacturers aim for high accuracy but may overlook the dangers. Too high pressure can weaken material integrity. A recent study highlighted that parts created at excessive pressure lost 10% of their strength. This is a counterproductive outcome for quality-focused production. Attention needs to be paid to molding pressure settings for better results.

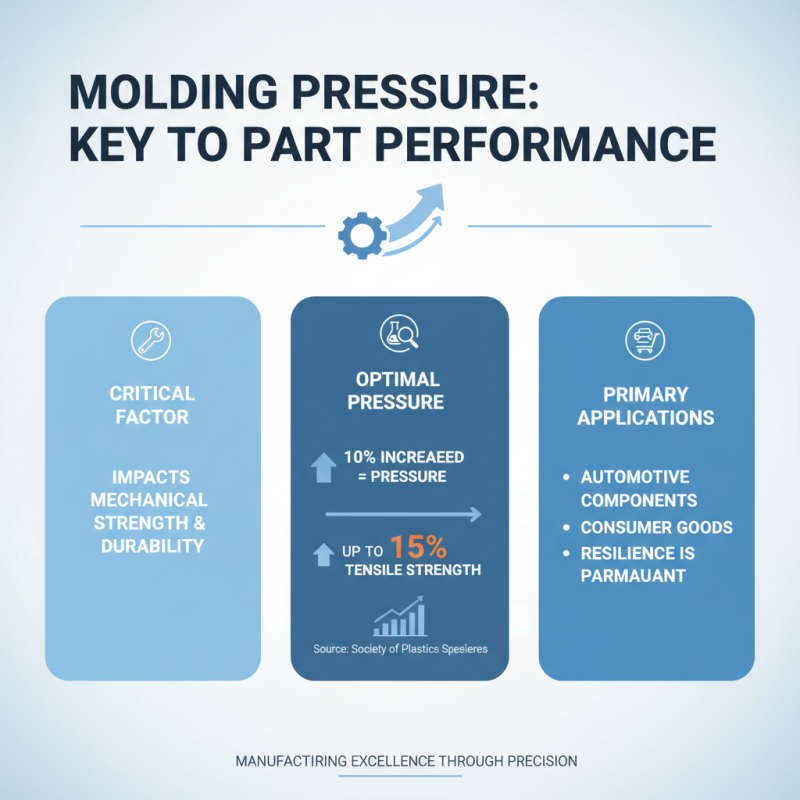

Molding pressure is a critical factor in manufacturing processes that greatly impacts the mechanical performance of parts. Studies show that optimal pressure levels can significantly enhance strength and durability. For instance, a report from the Society of Plastics Engineers indicates that increasing molding pressure by 10% can improve tensile strength by up to 15%. This is especially relevant in the production of automotive components and consumer goods, where resilience is paramount.

However, too much molding pressure can lead to defects. Over-compression may cause warpage or even cracking in finished parts. Manufacturers must find a balance between achieving high performance and avoiding damage. Pressure variations can lead to inconsistencies, making it crucial to monitor conditions closely. Interestingly, a 2022 survey by the International Manufacturing Technology Show highlighted that 30% of engineers faced challenges in optimizing molding pressure. Understanding this variability is essential for enhancing production efficiency.

In practical applications, adjusting both temperature and pressure synergistically can yield impressive results. For example, adjusting the molding temperature while fine-tuning pressure settings can lead to better flow rates and reduced cycle times. Yet, industries often struggle with maintaining these delicate balances under production constraints. Continuous testing and data analysis are vital to achieving targeted performance levels while minimizing waste. The journey towards perfecting molding pressure is ongoing, but it promises exciting advancements in manufacturing.

Molding pressure plays a critical role in manufacturing processes. Proper management of this pressure can lead to optimal product quality. Industry standards recommend adjusting molding pressure to meet specific material requirements. This ensures the finished products have the right density and structural integrity. However, not all manufacturers follow these guidelines consistently.

Many practices are based on trial and error. A few molds may not be tested under varied pressures. This oversight can result in defects or inconsistent results. High pressure might lead to over-compression and micro-cracks. Conversely, low pressure can cause incomplete fills. It’s crucial for companies to invest in pressure monitoring systems. Real-time adjustments can help achieve better outcomes.

Best practices include regular calibration of pressure gauges. Staff training is equally important. Operators should understand the implications of pressure variations. Not all teams prioritize this aspect, which is troubling. Ultimately, maintaining molding pressure is key to achieving efficiency. Exploring new methods for pressure management can lead to innovation in the field.