In the ever-evolving landscape of manufacturing, achieving optimal Mold Manufacturing practices is paramount for companies striving for excellence and competitiveness. According to a recent report by the Mold Manufacturing Association, companies that adopt advanced mold-making techniques see a reduction in production costs by up to 30% while simultaneously improving product quality and consistency. With the increasing demand for precision and rapid production timelines, exploring alternatives in mold materials and design processes has become essential. This ultimate guide aims to navigate the best practices in Mold Manufacturing, highlighting innovative alternatives that can enhance efficiency and sustainability in the industry. Whether it's through the adoption of advanced polymers or the integration of smart technology, understanding these alternatives can significantly impact production outcomes and drive long-term success.

Understanding the importance of mold manufacturing standards is vital for ensuring quality and efficiency in the production process. According to a report by Grand View Research, the global market for mold manufacturing is projected to reach $45 billion by 2027, with a compound annual growth rate (CAGR) of 3.5%. This growth underscores the need for stringent manufacturing standards that not only facilitate consistency but also enhance safety in operations. By adhering to established standards, manufacturers can mitigate risks associated with defects, improve product longevity, and foster customer satisfaction.

The International Organization for Standardization (ISO) has set forth several guidelines that mold manufacturers should follow to meet industry expectations. For instance, ISO 9001 not only addresses quality management systems but also emphasizes continuous improvement and customer focus. Research indicates that organizations implementing such standards can reduce production costs by up to 20% while increasing their market competitiveness. Furthermore, adherence to these standards encourages innovation, enabling manufacturers to adopt advanced technologies and materials that can lead to superior product development and a reduced environmental impact.

In the realm of mold manufacturing, identifying and addressing common challenges is crucial to enhancing the efficiency of production processes. One prevalent issue is the inconsistency in material quality. Variations in raw materials can lead to defects in the final product, which not only increases waste but also extends production time. Manufacturers need to establish stringent quality control measures and ensure suppliers meet specified standards to mitigate this risk.

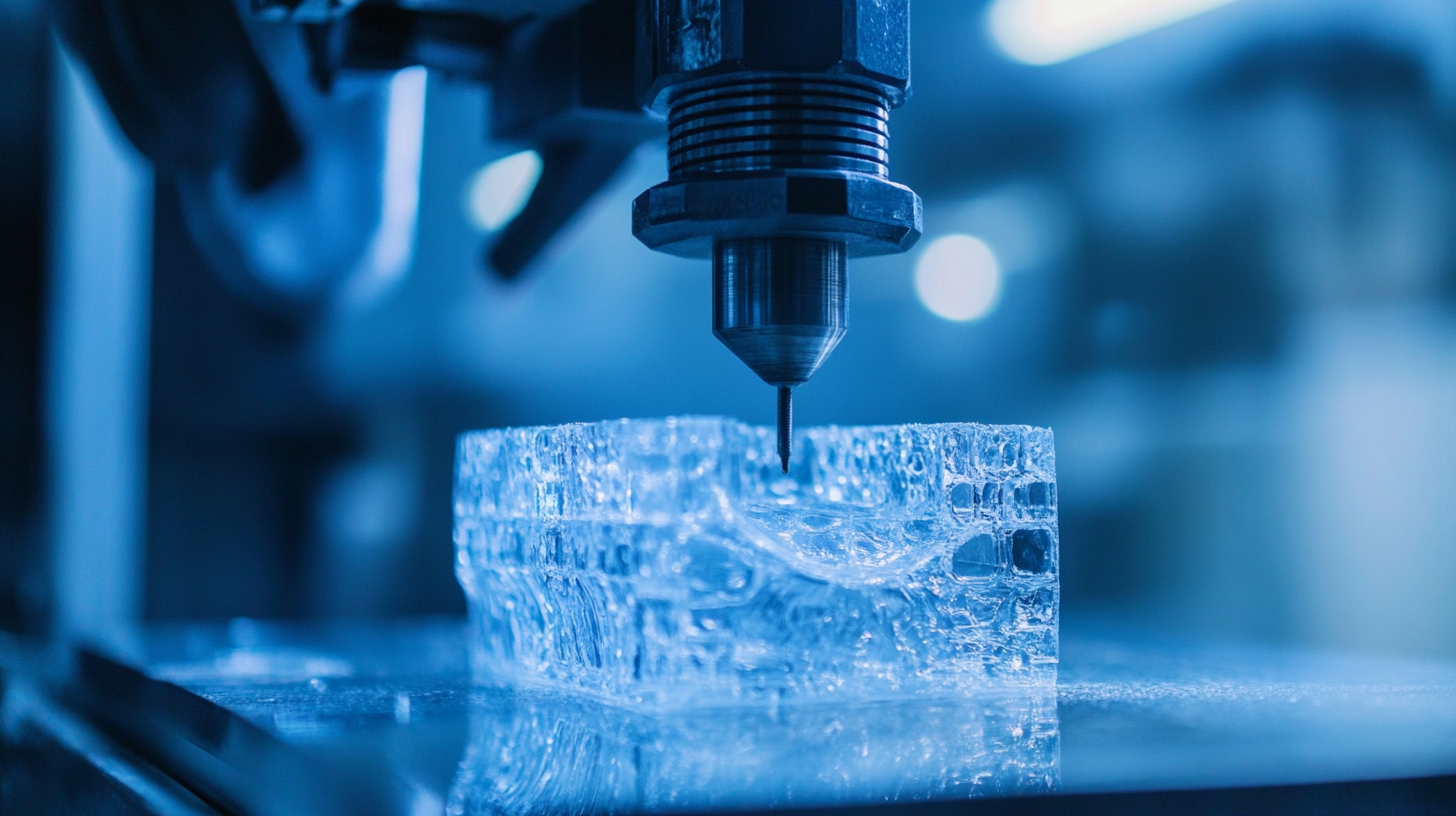

Another significant challenge is the integration of advanced technologies into existing processes. While innovations such as automation and 3D printing hold the potential to streamline operations, many manufacturers face difficulties in implementation. Resistance from employees accustomed to traditional methods can hinder progress. Training and demonstrating the long-term benefits of these technologies are essential steps to facilitate smooth transitions, thereby improving productivity and product quality in mold manufacturing.

This bar chart illustrates the common challenges faced in mold manufacturing processes and their respective impact levels. Understanding these challenges can help in implementing best practices to improve efficiency and quality in mold production.

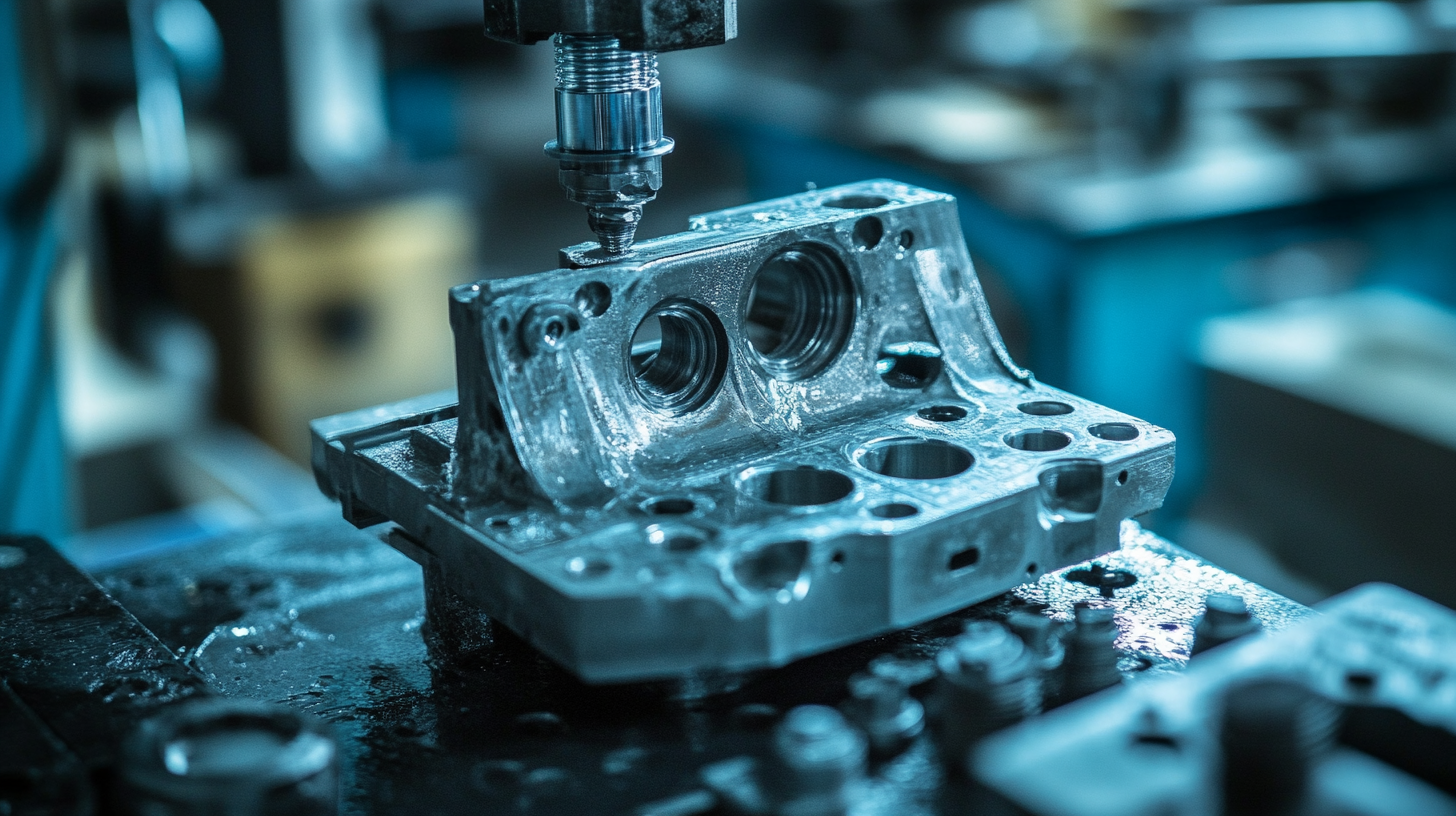

Quality control in mold production is essential for ensuring that the final products meet both industry standards and customer expectations. Implementing best practices begins with thorough material selection and inspection. Using high-quality materials from reputable suppliers can significantly reduce defects caused by material imperfections. Additionally, conducting regular quality checks throughout the manufacturing process helps identify and address issues before they escalate, ensuring a consistent quality of the end product.

Another critical aspect of quality control is rigorous testing of molds before they go into full production. This involves testing for dimensional accuracy, surface finish, and functionality. By utilizing advanced technologies such as 3D scanning and automated inspection systems, manufacturers can gain precise measurements and identify any variances from the desired specifications. Regular training for the production team on quality standards and practices also plays a vital role in maintaining high-quality output, fostering a culture of excellence throughout the manufacturing process.

| Dimension | Best Practice | Importance | Frequency |

|---|---|---|---|

| Material Inspection | Conduct thorough checks on raw materials | Ensures quality starts at the source | Every batch |

| Tool Calibration | Regularly calibrate molding machines | Maintains precision in production | Monthly |

| Process Monitoring | Implement real-time monitoring systems | Allows for immediate adjustments | Continuous |

| Quality Audits | Perform regular internal audits | Identifies areas for improvement | Quarterly |

| Employee Training | Provide ongoing training for staff | Enhances skillset and reduces errors | Annually |

In the realm of mold manufacturing, innovative solutions are paramount to addressing the myriad of challenges that arise throughout the production process. According to a recent industry report by Grand View Research, the global mold manufacturing market is expected to reach $9.39 billion by 2025, which underscores the critical need for effective problem-solving strategies in this competitive landscape. One of the most pressing issues remains the inconsistency in material quality, which can lead to significant production delays and increased costs. By leveraging advanced materials and implementing robust quality control measures, manufacturers can enhance the durability and reliability of molds, ultimately mitigating these common pitfalls.

Moreover, advancements in computer-aided design (CAD) and simulation technologies have revolutionized the way manufacturers approach mold design and testing. A report by MarketsandMarkets highlights that investments in digital twin technology can reduce time-to-market by up to 30%. This innovative approach allows manufacturers to create virtual models of their molds and simulate various conditions, enabling them to identify potential issues before physical production begins. By embracing such cutting-edge technologies, businesses can not only streamline their manufacturing processes but also ensure the highest standards of quality are met, leading to greater customer satisfaction and loyalty.

The mold manufacturing industry is undergoing significant transformations driven by technological advancements and evolving market demands. One of the key trends shaping the future of mold manufacturing is the integration of automation and robotics. These technologies enhance precision and efficiency, allowing manufacturers to reduce cycle times and improve product quality. Automated processes not only minimize human error but also optimize resource allocation, leading to cost savings that can be passed down to customers.

Another crucial trend is the growing emphasis on sustainability in mold manufacturing practices. As industries face increasing pressure to reduce their environmental impact, manufacturers are adopting eco-friendly materials and processes. This shift not only aligns with global sustainability goals but also meets the expectations of environmentally conscious consumers. Incorporating additive manufacturing techniques further enhances design flexibility and reduces waste, positioning companies to be more competitive in a rapidly evolving marketplace. Embracing these best practices not only prepares manufacturers for the future but also fosters innovation in product development and production methodologies.