As we look to the future of product molding, it is essential to recognize how innovative technologies are reshaping the manufacturing landscape. According to a recent report by MarketsandMarkets, the global injection molding market is projected to reach $242.4 billion by 2025, growing at a CAGR of 5.5% from 2020. This growth is driven by advancements in automation, materials science, and sustainability practices that are transforming traditional molding processes.

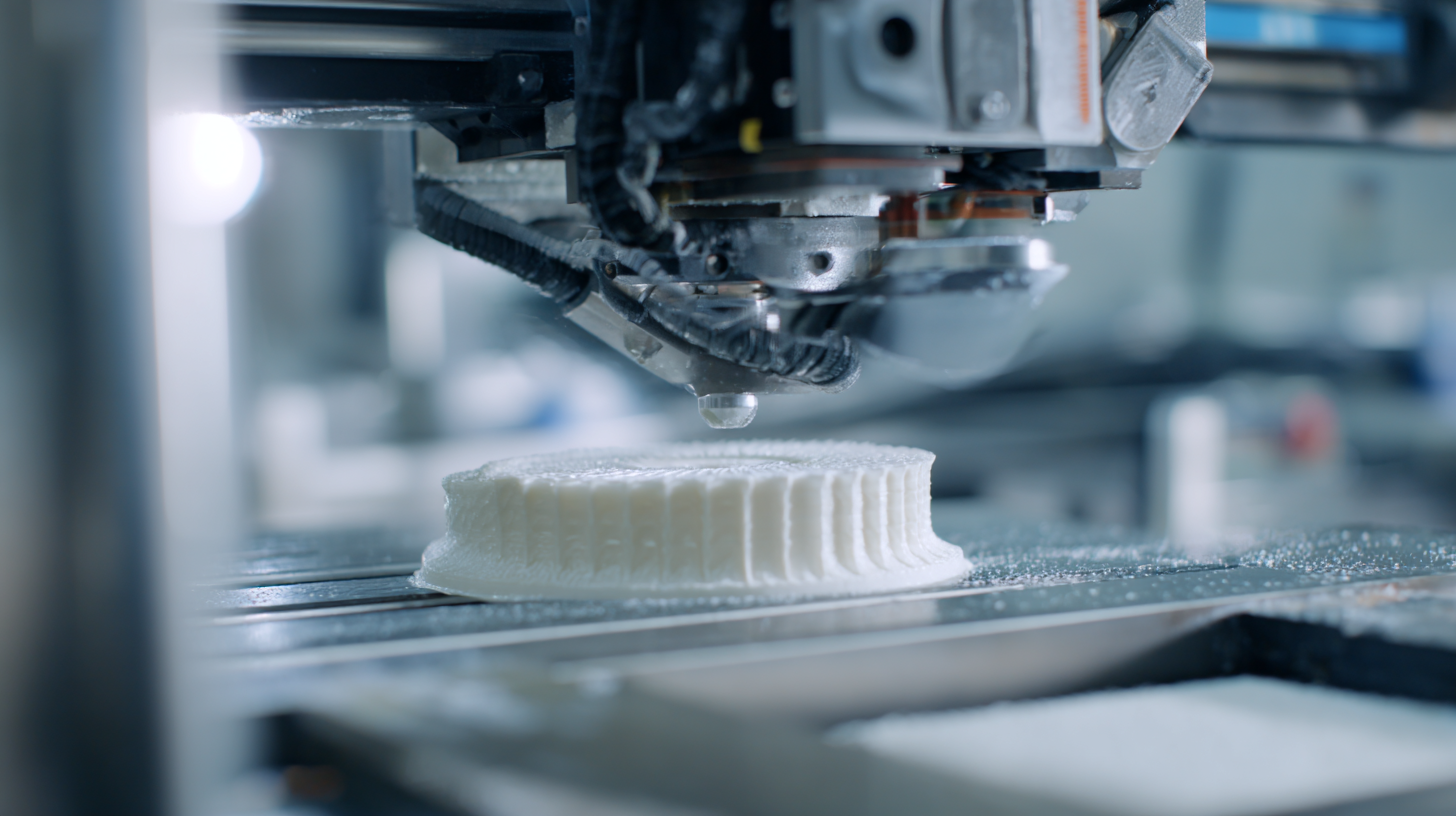

Industry leaders are leveraging integrated solutions such as 3D printing and advanced simulation technologies to enhance efficiency and reduce waste. Furthermore, a study by Grand View Research highlights that the demand for lightweight materials and eco-friendly production methods is transforming product molding techniques, enabling manufacturers to meet the increasing consumer expectations for sustainable products. As these innovations continue to evolve, the product molding industry stands at the forefront of redefining manufacturing practices for a more competitive and sustainable future.

The market for high-performance plastics is poised for significant growth, driven by increasing demand across various industries including transportation and electronics. Innovations in materials such as fluoropolymers, polyamides, and liquid crystal polymers (LCP) are at the forefront of enhancing product performance. The ability to harness these advanced materials allows manufacturers to produce components that are not only lighter but also exhibit superior durability and resistance to extreme conditions, which is essential in applications ranging from automotive to electrical sectors.

In particular, the polyurethane market showcases substantial growth potential, projected to rise from $91.49 billion in 2024 to $135.08 billion by 2032. This trajectory is reflective of broader trends in manufacturing, where the integration of advanced materials facilitates the development of products that meet increasingly stringent performance standards. Furthermore, emerging technologies and innovative molding techniques are expected to transform the landscape of product development, aligning with the ongoing push for sustainability and efficiency in manufacturing processes.

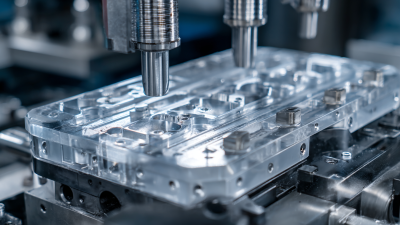

The integration of automation and robotics in molding processes is reshaping the future of product manufacturing. Advanced robotics systems are increasingly being implemented in injection molding workshops, exemplified by the deployment of humanoid robots, which enhance efficiency and precision. These innovations enable manufacturers to optimize production workflows, significantly improving turnaround times and reducing operational costs. As companies embrace smart manufacturing technologies, they can leverage AI and collaborative robots to ensure consistent quality in their products.

At industry exhibitions such as K 2025, manufacturers are showcasing the latest advancements in modular automation and digitalisation. These advancements allow for greater flexibility in production lines, adapting quickly to changing demands and facilitating the customization of products. Enhanced safety and productivity are achieved through user-friendly machine tending solutions, which seamlessly integrate with existing equipment, further streamlining operations. The focus on sustainability, alongside efficiency, positions automation as a critical component in the evolution of molding processes, paving the way for a more innovative and environmentally conscious manufacturing landscape.

Digital twins are revolutionizing the product design and testing phases in manufacturing, offering a powerful avenue for innovation. By creating virtual replicas of physical products, manufacturers can simulate and analyze various scenarios before production, significantly reducing time and cost. This technology enables designers to explore intricate details and assess performance under multiple conditions, which enhances the decision-making process and fosters creativity in product development.

Moreover, digital twins facilitate real-time feedback during the testing phase. As products undergo virtual tests, manufacturers can make instantaneous adjustments based on data-driven insights. This iterative process not only improves the quality of the final product but also allows for rapid prototyping. As companies embrace these innovations, they can stay ahead of the competition, responding swiftly to market demands and ultimately leading to more efficient and sustainable manufacturing practices.

The trend towards sustainable practices in product molding technologies is reshaping the manufacturing landscape. As the molded fiber packaging market continues to expand, it is projected to grow significantly due to the increasing preference for eco-friendly alternatives over traditional packaging materials. This growth aligns with the anticipated rise of the molded fiber packaging market from $8.5 billion in 2024 to $13.5 billion by 2032, marking a compound annual growth rate of 5.97%. Manufacturers are adopting more sustainable methods, incorporating renewable resources and reducing waste, which is becoming a pivotal strategy in the industry.

In the realm of polymer materials, the C6-LLDPE market is also experiencing a notable shift, expected to reach 25,094.28 million by 2033 from 18,835.01 million in 2025, growing at a rate of 3.7%. This trend reflects the broader push for sustainable production, as companies leverage advanced technologies, such as AI, to enhance efficiency and innovation in the rubber and plastic sectors. This continuous adaptation indicates a significant shift towards smarter, more sustainable manufacturing processes, ensuring that the industry meets both consumer demands and environmental standards.

In the rapidly evolving manufacturing landscape, staying ahead of market trends is crucial for businesses looking to thrive. The advent of new technologies such as artificial intelligence, which is expected to significantly grow in the UK market by 2032, allows manufacturers to enhance efficiency and streamline operations. By leveraging AI, companies can analyze vast amounts of data to identify trends, reduce waste, and improve product quality, thereby ensuring they remain competitive.

Moreover, the rise of digital transformation in manufacturing is set to create an estimated $800 billion market by 2032, driven by a compound annual growth rate of 9.36%. This transformation demands that businesses adopt innovative approaches to their processes, such as incorporating microservices architecture to enhance agility and responsiveness. As industries shift towards more automated and data-driven environments, companies must stay informed of these trends and continuously adapt to leverage new technologies, ensuring their place in the future of manufacturing.

| Innovation | Description | Impact on Manufacturing | Market Trend | Estimated Adoption Year |

|---|---|---|---|---|

| 3D Printing | Layer-by-layer additive manufacturing allows for complex geometries and reduced waste. | Increases design flexibility and reduces production costs. | Growing demand for custom products. | 2025 |

| Smart Molding Technology | Integration of IoT in molding machines for real-time monitoring of production. | Enhances efficiency and minimizes downtime. | Increase in automation and data analytics. | 2024 |

| Bio-based Materials | Use of biodegradable and sustainable materials for product manufacturing. | Reduces environmental footprint and caters to eco-conscious consumers. | Rising sustainability trends in manufacturing. | 2026 |

| Advanced Simulation Software | Software tools for virtual testing of molds and product designs before production. | Reduces trial and error in the prototyping phase. | Emphasis on rapid prototyping and product development cycles. | 2023 |

| Hybrid Manufacturing Techniques | Combining traditional molding processes with additive manufacturing. | Facilitates the production of complex parts that were not possible before. | Emerging interest in multiprocess capabilities. | 2027 |