Injection molding is a critical manufacturing process used extensively across various industries, from automotive to consumer products, with the global injection molding market projected to reach $329.13 billion by 2025, according to a report by Grand View Research. Among the numerous factors influencing the quality and efficiency of injection molding, injection molding pressure stands out as a pivotal parameter that directly affects product dimensions, mechanical properties, and cycle time. A comprehensive understanding of how to optimize injection molding pressure can lead to significant improvements in production efficiency and cost savings. However, achieving the ideal pressure settings is not always straightforward, as various materials and designs may require tailored approaches. This guide presents seven essential tips for global buyers aiming to enhance their injection molding processes through effective pressure optimization strategies, ultimately helping them to stay competitive in an increasingly demanding market.

Understanding injection molding pressure

is crucial for ensuring high-quality production. Pressure control not only affects the molding process but also plays a significant role in the final product's integrity. Recent advancements highlight the importance of cavity pressure as a key indicator for maintaining stable injection molding conditions. By monitoring cavity pressure, manufacturers can predict quality outcomes and make necessary adjustments to minimize defects.

To optimize injection molding pressure, consider these essential tips: First, precisely calibrate the holding pressure based on real-time cavity pressure measurements. This adjustment enhances consistency, reduces cycle time, and improves part quality. Second, analyze the influence of recyclate content carefully; varying the virgin and recyclate mixture ratios can significantly impact both process stability and final part quality. Employing advanced methodologies, such as simulation-driven designs, can further refine the mold design, addressing critical factors like gate placement and weld line management to achieve optimal results. With these strategies, global buyers can ensure superior quality in their injection-molded products.

When it comes to optimizing injection molding pressure, several key factors come into play. The first is material selection. Different polymers have varying viscosities, which can significantly influence pressure requirements. It’s essential to choose a material that suits both the design and the intended function of the final product. Incorporating the right material not only streamlines the molding process but also enhances the overall quality of the product.

Another critical aspect is temperature control. Maintaining optimal temperature throughout the injection process is crucial for ensuring a uniform material flow. By carefully monitoring both the injection temperature and the mold temperature, manufacturers can reduce the risk of defects such as warping or incomplete filling. To achieve this, it’s advisable to implement advanced temperature management systems that can adapt in real-time.

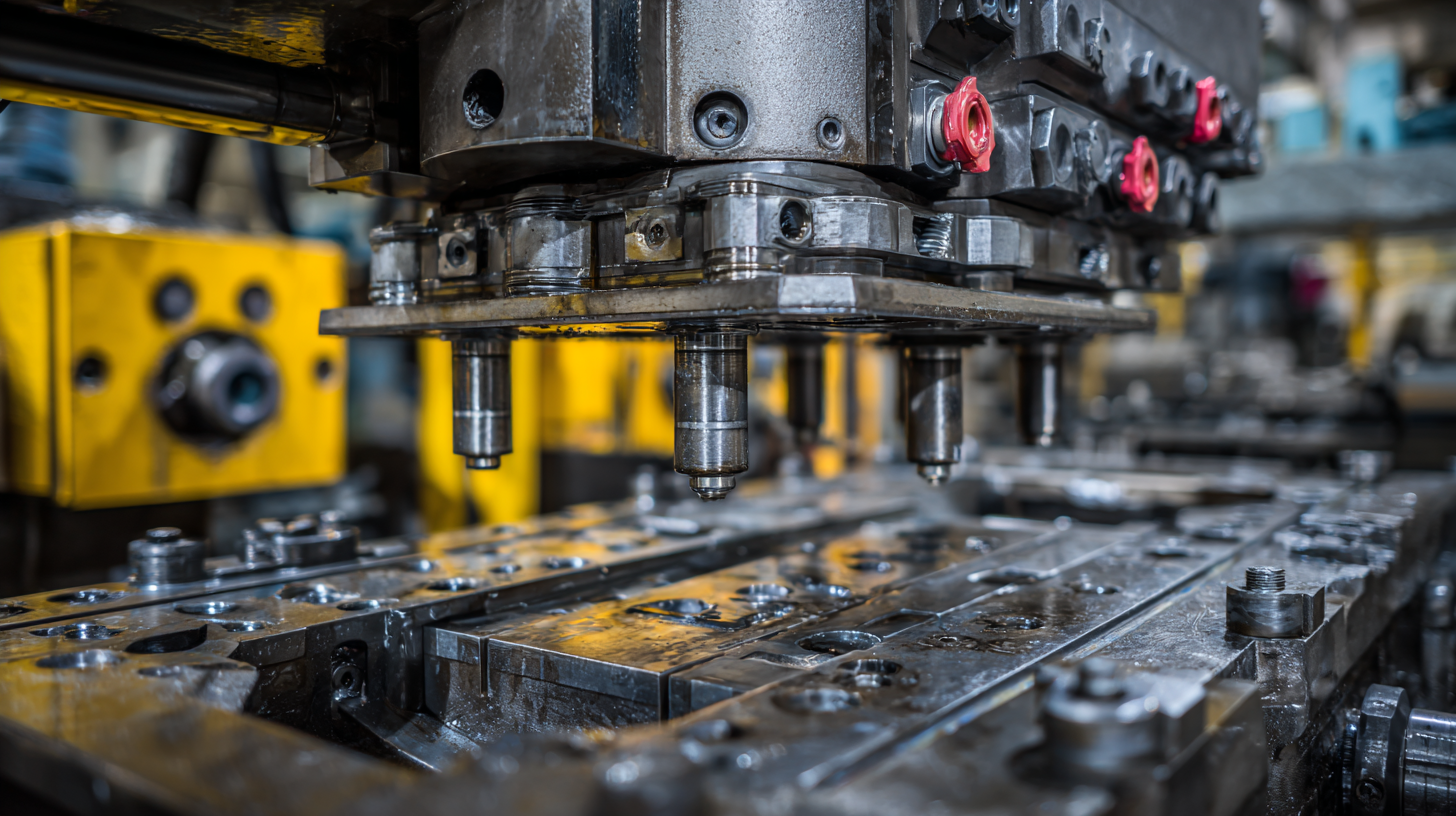

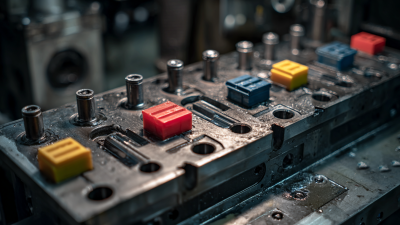

Additionally, understanding the role of mold design is vital. A well-designed mold can facilitate efficient material flow, thus minimizing required injection pressure. For best results, consider incorporating features like adequate venting and balanced flow paths. This not only optimizes pressure but also speeds up the production cycle, ultimately leading to improved productivity and cost efficiency.

Adjusting injection molding pressure is a critical step in the manufacturing process, but it often comes with its own set of challenges. One of the most common issues faced by manufacturers is inconsistent pressure. This can lead to variations in the final product quality, such as dimensional inaccuracies and surface defects. To mitigate this, it’s important to establish a robust monitoring system that tracks pressure fluctuations in real-time, allowing for immediate corrective actions.

Another significant challenge is the relationship between injection pressure and material characteristics. Different materials respond uniquely to pressure adjustments, affecting the flow behavior and cooling rates. Global buyers must understand the specific properties of the materials they are using, which requires thorough testing and validation. Additionally, improper pressure settings can cause problems like jetting or incomplete filling, ultimately resulting in increased scrap rates. It’s essential to conduct simulations and trials to identify the optimal pressure settings tailored to each material and product design.

When it comes to injection molding, maintaining optimal pressure is crucial for producing high-quality parts. One of the best practices for monitoring molding pressure is to utilize advanced sensors. These sensors can provide real-time feedback on pressure changes, enabling operators to make immediate adjustments. Implementing a closed-loop control system can significantly enhance consistency, reducing the risks of defects and ensuring that molds are filled correctly.

When it comes to injection molding, maintaining optimal pressure is crucial for producing high-quality parts. One of the best practices for monitoring molding pressure is to utilize advanced sensors. These sensors can provide real-time feedback on pressure changes, enabling operators to make immediate adjustments. Implementing a closed-loop control system can significantly enhance consistency, reducing the risks of defects and ensuring that molds are filled correctly.

Another effective strategy is to conduct regular maintenance checks on your injection molding equipment. Wear and tear on machinery can lead to fluctuations in pressure, compromising the integrity of the molded parts. By scheduling routine inspections and replacing worn components, you can maintain a stable pressure profile. Additionally, investing in training for your operators can help them understand how to analyze pressure trends and recognize when adjustments are needed.

Lastly, it’s essential to document pressure settings and their outcomes meticulously. This data can help identify patterns and optimize the production process over time. By leveraging historical data, you can fine-tune your pressure parameters, leading to improved efficiency and quality in your injection molding operations.

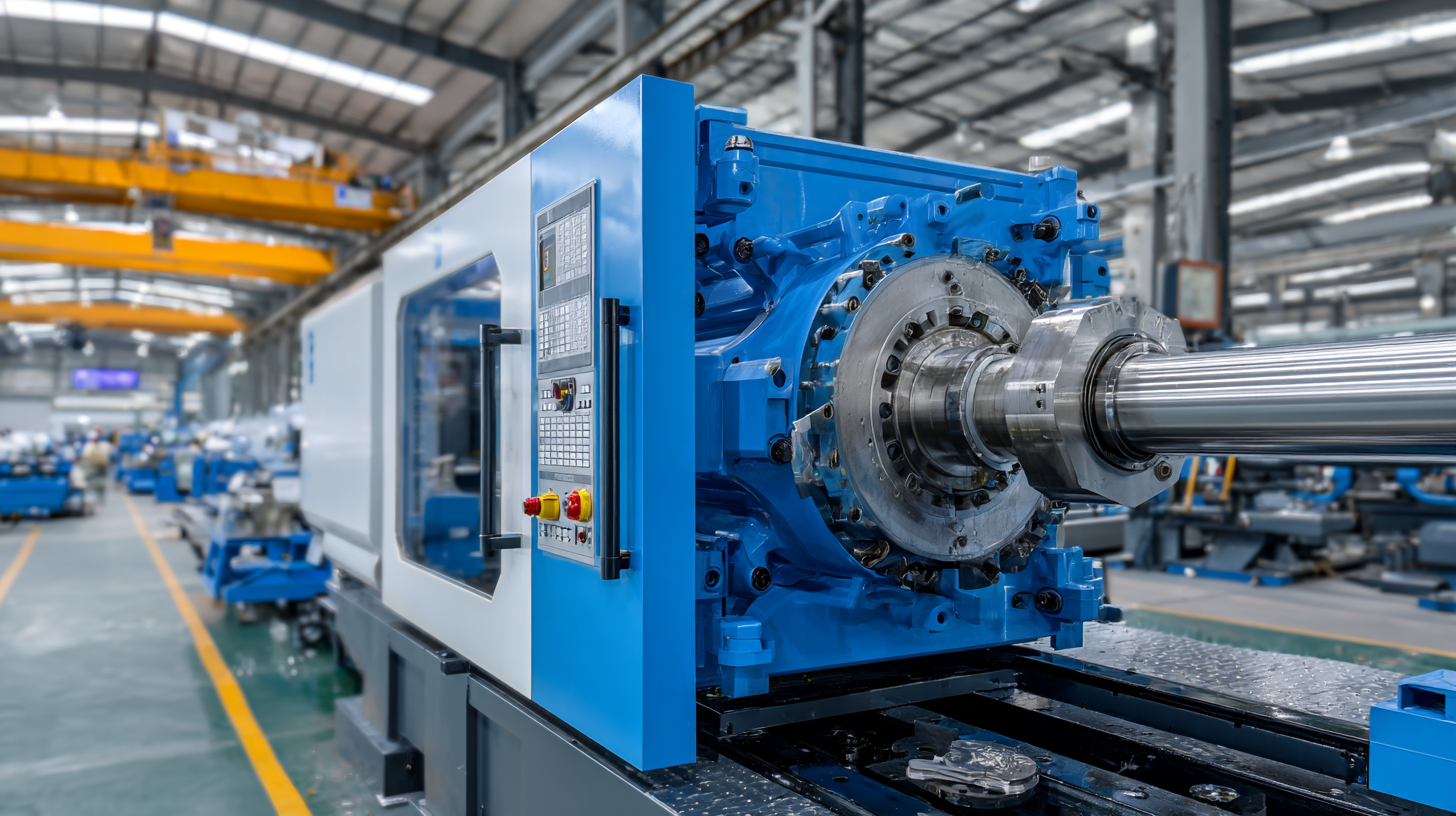

Innovative technologies are revolutionizing the way we control injection molding pressure, making the process more efficient and reliable. Advanced sensors and real-time monitoring systems are key to achieving optimal pressure settings. By utilizing these technologies, manufacturers can detect fluctuations instantly and adjust parameters on the fly, ensuring that the integrity of the molded parts is maintained throughout the production cycle.

To optimize injection molding pressure, one essential tip is to regularly calibrate your machinery. Calibration ensures that your machines are operating within the specified pressure range, reducing the risk of defects and material waste. Additionally, incorporating automation into the pressure control process can provide consistent results and minimize human error, leading to higher productivity and quality.

Another important aspect is to invest in simulation software that can predict how changes in pressure will affect the final product. With accurate simulations, manufacturers can make informed adjustments before the actual molding process begins. This proactive approach not only saves time but also enhances the overall efficiency of the production line, allowing for quicker turnaround times and better resource allocation.