When embarking on a project that involves plastic manufacturing, selecting the correct molding mold is critical to achieving the desired product specifications and overall project success. According to a report by Smithers Pira, the global market for plastic molding is expected to reach approximately $658 billion by 2024, underscoring the significant role that molding molds play in the manufacturing process. Choosing the right molding mold not only affects the efficiency of production but also influences the quality, precision, and durability of the end products.

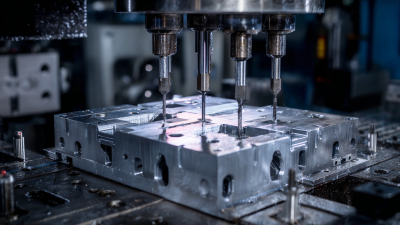

Molding molds come in various types, each tailored for specific applications and materials. As emphasized by the American Society of Plastics Engineers, understanding the technical requirements of different molding processes—such as injection molding, blow molding, and compression molding—is essential for making informed decisions. With advancements in technology and materials, selecting the most suitable molding mold can lead to substantial cost savings and enhanced product performance, making it imperative to consider factors such as mold design, material compatibility, and production volume before finalizing your choice.

When selecting the right molding mold for your project, it’s crucial to understand the different types available, as each serves a unique purpose. The most common types include injection molds, blow molds, and compression molds.

According to a report by Grand View Research, the global injection molding market size was valued at $246.7 billion in 2021 and is expected to expand at a compound annual growth rate (CAGR) of 5.3% from 2022 to 2030. This growth highlights the increasing demand for precision and intricacy, where injection molds excel in producing complex and high-volume parts.

Blow molds, on the other hand, are primarily used for creating hollow objects like bottles and containers. The demand for blow molding has also seen significant growth, particularly driven by the beverage and packaging industries. A study by Research and Markets states that the global blow molding market was valued at $65.92 billion in 2022 and is projected to reach $108.14 billion by 2028, growing at a CAGR of 9.01%. Understanding these varying mold types and their applications will help you choose the right one to meet both your design and functional requirements efficiently.

When selecting the appropriate molding mold for your project, assessing material compatibility is crucial. Different materials interact uniquely with molds, which can significantly impact the quality and durability of your final product. For instance, the Thermoplastics and Thermosetting Resins Industry report indicates that using the wrong mold material can result in a failure rate of up to 30% in production. This not only leads to wasted resources but can also delay project timelines.

When evaluating material compatibility, consider factors such as thermal properties, chemical resistance, and the intended processing methods. For example, silicone molds are ideal for applications involving low durometer materials due to their flexibility, while aluminum molds are best for high-volume production with materials like PVC due to their excellent thermal conductivity.

Tips: Always conduct preliminary tests with small batches to ensure compatibility before moving to full-scale production. Additionally, staying updated on industry standards and material innovations is vital. Reports from sources like the American Society for Testing and Materials (ASTM) can provide valuable insights into the latest advancements in molding technologies and material performance.

When selecting the appropriate molding mold for your project, evaluating the complexity of your design requirements is crucial. According to a recent industry report by the Global Plastic Molding Market, nearly 35% of unsuccessful projects stem from insufficient design evaluation and complexity misunderstanding. This highlights the importance of initiating your project with a thorough analysis of the required mold features. Consider the intricacies of shapes and the precision required in your final product, as high complexity often necessitates advanced mold-making techniques and materials.

**Tips:** Always sketch your design ideas and use 3D modeling software to visualize complexity. This approach can help identify potential challenges early on, which can save time and resources down the line.

Additionally, it's essential to assess the materials involved in your design. The compatibility of the chosen material with the mold can significantly affect production efficiency and product quality. Data from the Manufacturing Industry Spokesperson indicates that 40% of increased production costs can be attributed to improper material selection, which can complicate the molding process or even lead to failures. Thus, evaluating your material choices in conjunction with your design complexity is vital for achieving optimal results.

**Tips:** Engage with mold designers early in the project to gain insights on material properties and design adaptability. This collaboration can effectively bridge the gap between design intent and manufacturing feasibility.

When selecting the right molding mold for your project, one of the most crucial factors to consider is the production volume. Understanding your expected output will help guide your choice of materials and design. For low-volume production, such as prototype testing or limited batch runs, utilizing softer materials or less complex molds can be cost-effective. In contrast, high-volume projects warrant investing in more durable molds, often made from metal, to withstand the pressures of consistent use and to ensure high precision across numerous runs.

Cost-effectiveness also plays a significant role in the mold selection process. Budget constraints and the overall financial feasibility of your project must align with the anticipated production scale. While initial costs of high-quality molds might be daunting, they often pay off through reduced cycle times, minimal maintenance, and improved product quality over time. For projects with tight budgets, exploring options such as 3D printed molds can provide an economical solution, although they may not offer the same longevity as traditional molds. Balancing these factors is essential for a successful molding project, ensuring that both the production efficiency and financial metrics meet your project's needs.

| Mold Type | Production Volume (Units/Month) | Cost per Mold ($) | Material Used | Suitability for Projects |

|---|---|---|---|---|

| Injection Mold | 1000+ | 5,000 | Steel | High-volume production |

| Blow Mold | 500-2000 | 8,000 | Aluminum | Beverage containers |

| Thermoforming Mold | 300-1200 | 3,000 | Plastic | Packaging products |

| Compression Mold | 200-1000 | 4,500 | Rubber | Auto parts |

| CNC Mold | 50-500 | 2,500 | Various metals | Prototyping |

Maintaining the longevity of molding molds is crucial for any project, as proper care can significantly extend the life of your equipment.

Regular cleaning is one of the best practices to ensure that molds remain in optimal condition. After each use, it's essential to remove any residual materials,

as residues can lead to degradation and contamination. Using gentle, non-abrasive cleaners helps to protect the mold surface,

while a thorough rinse ensures that no cleaning agents are left behind to interfere with future projects.

Another important aspect of mold maintenance is proper storage. Molds should be kept in a climate-controlled environment,

away from direct sunlight and extreme temperatures, which can warp or damage the material. Implementing a routine inspection schedule can identify

wear and tear before they become significant issues, allowing for timely repairs.

Additionally, considering the use of protective coatings can provide an extra layer of defense against environmental factors that may shorten

the lifespan of the mold. Following these best practices not only preserves the quality of the molds

but also enhances overall project efficiency.