Choosing the right machine mold is crucial for the success of any manufacturing project. According to the latest report from the International Mold Association, over 60% of manufacturing failures link back to improper mold selection. Such a statistic highlights the importance of careful consideration. Industry experts, like Dr. James Caldwell, state, "Selecting the appropriate machine mold can significantly impact production efficiency and product quality."

Various factors influence your choice of machine mold. Material compatibility, mold design, and production volume are just a few. Often, manufacturers overlook these details, leading to costly errors. For instance, using a mold that doesn’t match the plastic properties can cause defects. These challenges serve as a reminder to reflect on every decision in the mold selection process.

Understanding your project's specific needs is essential. While you may think you know what works best, the nuances of machine mold selection often reveal gaps in knowledge. Taking the time to research and consult with experts can make a notable difference. In the evolving landscape of manufacturing, the right machine mold can set you apart.

When choosing the right machine mold, it’s crucial to understand the types available. Molds can be categorized into several groups, including injection molds, blow molds, and compression molds. Each type has unique features and applications, directly influencing production efficiency and cost. For instance, injection molds are highly precise, making them ideal for complex designs. Data from the Plastics Industry Association indicates that injection molding accounts for over 30% of the entire plastics market.

Blow molds, on the other hand, are designed for hollow objects. They are commonly used for bottles and containers. According to a report by MarketsandMarkets, the blow molding market is projected to grow at a CAGR of 5.9% over the next five years. This growth indicates an increasing demand for lightweight and sustainable packaging solutions.

Compression molds are less common but still essential. They are predominantly used in producing thermosetting plastics. A potential downside? They can sometimes result in longer production times due to the curing phase. Each mold type has its pros and cons, and understanding these differences is key to selecting the best option for your specific project needs.

Choosing the right machine mold is critical for project success. Several key factors play a role in this decision. First, consider the material you will be working with. Different materials require molds designed to handle their specific properties. For instance, some materials need higher temperatures than others.

Tip: Always review the compatibility of your chosen mold material with the production material.

Next, think about the production volume. High-volume projects might need durable molds that withstand repeated use. On the other hand, low-volume projects may benefit from less expensive options. The mold's design complexity also affects your choice. A more intricate design might require advanced capabilities.

Tip: Sketch your design ideas. Visualizing can help identify mold requirements early.

Lastly, budget considerations are vital. Molds can vary significantly in price. It's important to balance quality with cost without compromising your project's needs. Remember, a cheaper mold might lead to greater costs later.

Tip: Always factor in potential repair and maintenance costs when budgeting.

| Factor | Description | Importance |

|---|---|---|

| Material Type | Choose a mold material suited for the application, such as steel or aluminum. | High |

| Design Complexity | Assesses the intricacy of the mold's shape and features. | Medium |

| Production Volume | Consider the number of parts required to determine mold durability. | High |

| Lead Time | The time required to fabricate the mold before production begins. | Medium |

| Cost | Evaluate the total cost of mold manufacturing and maintenance. | High |

| Mold Cooling System | Incorporates features to manage the temperature during the process. | Medium |

| Mold Maintenance | The ease of maintaining the mold affects its longevity and efficiency. | Medium |

| Compatibility | Ensure the mold is compatible with the intended machine and production process. | High |

Choosing the right material for your machine mold is crucial. Every project has unique needs. Compatibility between the mold material and the product material affects the final outcome. For instance, thermoplastics and thermosets behave differently. If you’re not careful, distortion may occur during production.

When selecting materials, consider temperature resistance and chemical stability. A mold that can't withstand high temperatures may fail quickly. Look for materials that resist wear and tear. It’s essential to think about the lifespan of both the mold and the product.

Sometimes, testing is necessary to evaluate compatibility. You might find that what seemed suitable initially didn’t work in practice. It’s a learning curve. Don’t ignore the importance of feedback from previous projects. Adjust your approach based on past experiences. This will guide you to make better choices in future endeavors.

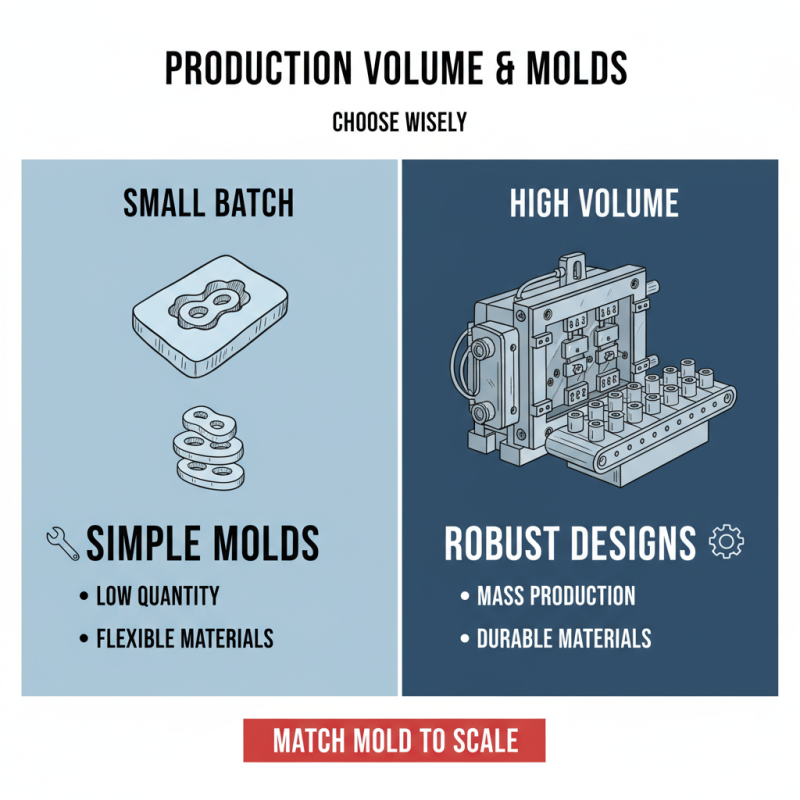

When assessing production volume, it is crucial to understand your project's scale. A small batch may only require a simple mold. On the other hand, high-volume production calls for robust designs. Consider materials and construction methods carefully. Different molds suit different needs. A mold designed for small quantities might break under strain in mass production.

Durability is equally important. Molds need to withstand wear over time. Think about how often you will use the mold. High durability may initially be costly. Yet, it saves money long-term by reducing maintenance and replacement needs. Make sure to analyze the expected lifetime of the mold. This can affect your project timeline and budget.

Sometimes, it’s hard to predict how production demands will change. Adjustments might be needed after initial assessments. Choosing a mold is not a one-time decision. Regular evaluations can help align the mold's performance with ongoing project needs. Be open to refining your choice as production scales. The right mold influences both the process and the final product quality.

When budgeting for machine molds, costs can vary significantly based on multiple factors. According to a report from the American Society of Manufacturing Engineers, the average cost for a standard injection mold ranges from $5,000 to $100,000. Complex molds can even exceed this range. It's essential to analyze the specific requirements of your project. The material, design complexity, and production volume all influence the final price.

In terms of value, a higher upfront cost may lead to increased durability and precision. A well-made mold can produce thousands of parts, lowering the cost per unit over time. However, not all projects justify high mold costs. For smaller production runs, investing in expensive molds may not be viable. Consideration of lifecycle costs is key. Balancing initial expenditure with long-term benefits is crucial.

Understanding these financial aspects helps you make informed decisions. While you aim for quality, reflect on your budget constraints. Sometimes, cheaper options lead to unexpected expenses later. Carefully evaluate your project's scale and objectives before making a final decision. Each choice could impact your overall success.