When it comes to manufacturing plastic parts, the selection of the appropriate injection molding mold is critical for achieving optimal results. With the wide array of materials and designs available, choosing the right injection molding mold can impact everything from product quality to production efficiency and costs. This guide aims to demystify the process of selecting an injection molding mold that fits your specific manufacturing needs. We will explore key factors such as mold design, material selection, production volume, and budget considerations, providing you with the insights needed to make informed decisions. Whether you are a seasoned manufacturer or new to the world of injection molding, understanding these elements will empower you to choose a mold that not only meets your immediate requirements but also supports your long-term production goals.

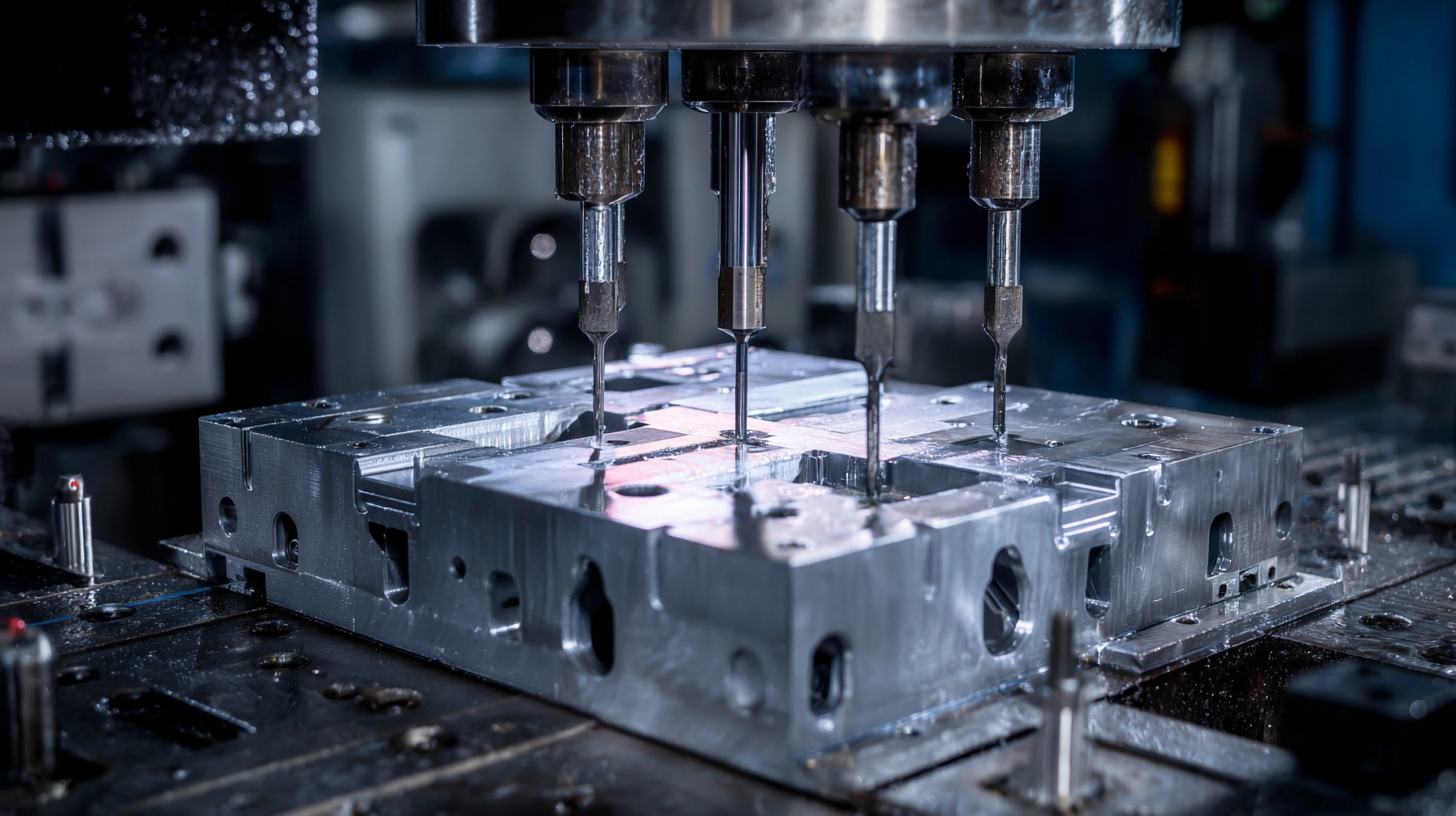

When selecting the right injection molding mold for your manufacturing needs, it is essential to understand the different types available and their applications. The injection molding process relies heavily on the mold's design, which directly impacts product quality, cycle time, and production efficiency. According to a report from Grand View Research, the global injection molding market is projected to reach $381.39 billion by 2030, underscoring the increasing demand for high-quality molds across various industries.

In general, molds can be categorized into two main types: single-cavity and multi-cavity molds. Single-cavity molds are ideal for prototypes or small production runs, allowing manufacturers to create one part per cycle. On the other hand, multi-cavity molds significantly increase production efficiency by allowing multiple parts to be formed simultaneously, which is especially beneficial in high-demand environments. Industry data from Mordor Intelligence indicates that multi-cavity molds can enhance productivity by up to 60%, demonstrating their crucial role in scaling up production for mass-market items such as automotive components and consumer goods.

Understanding these mold types will empower manufacturers to make informed decisions tailored to their specific application needs.

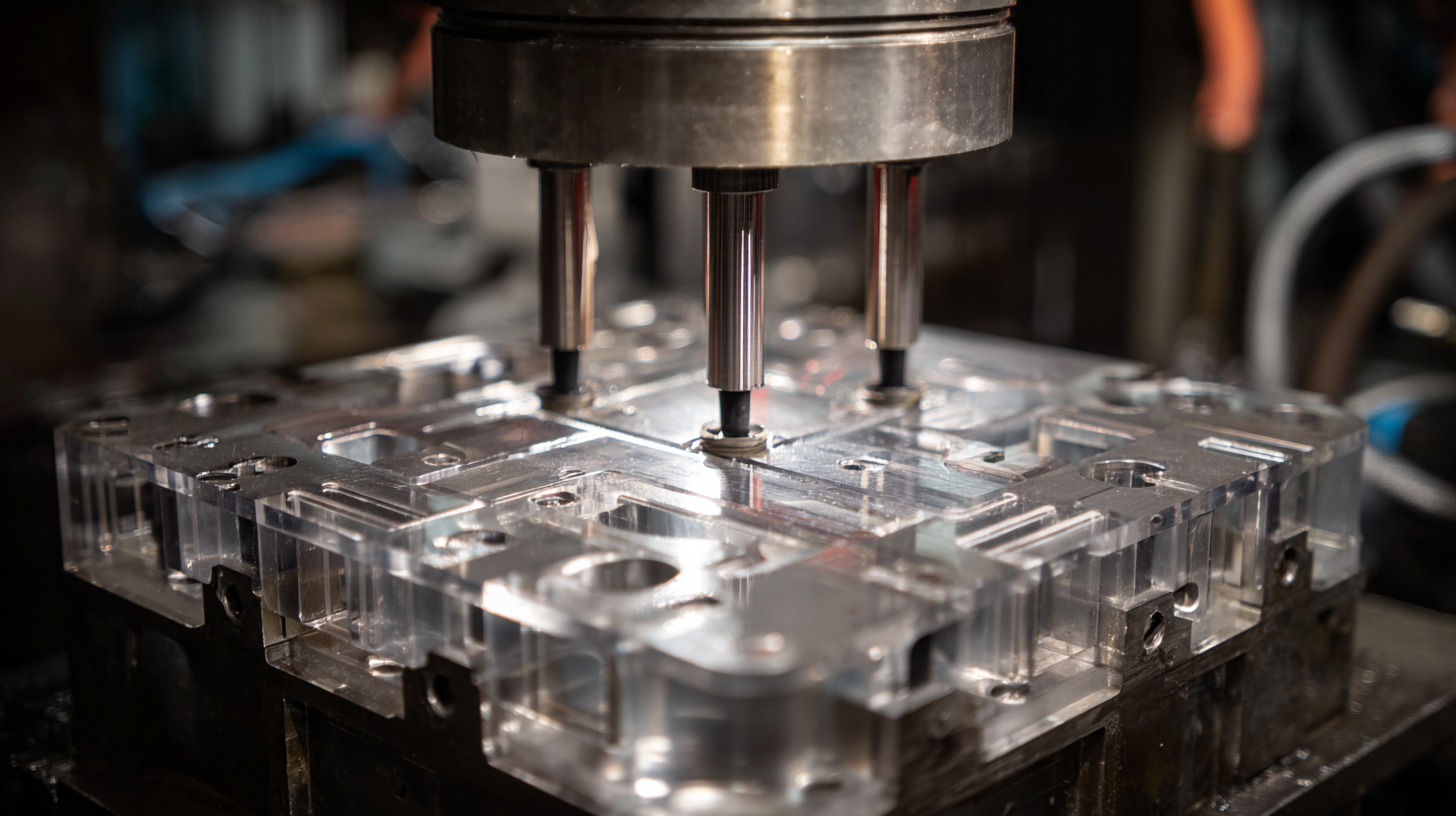

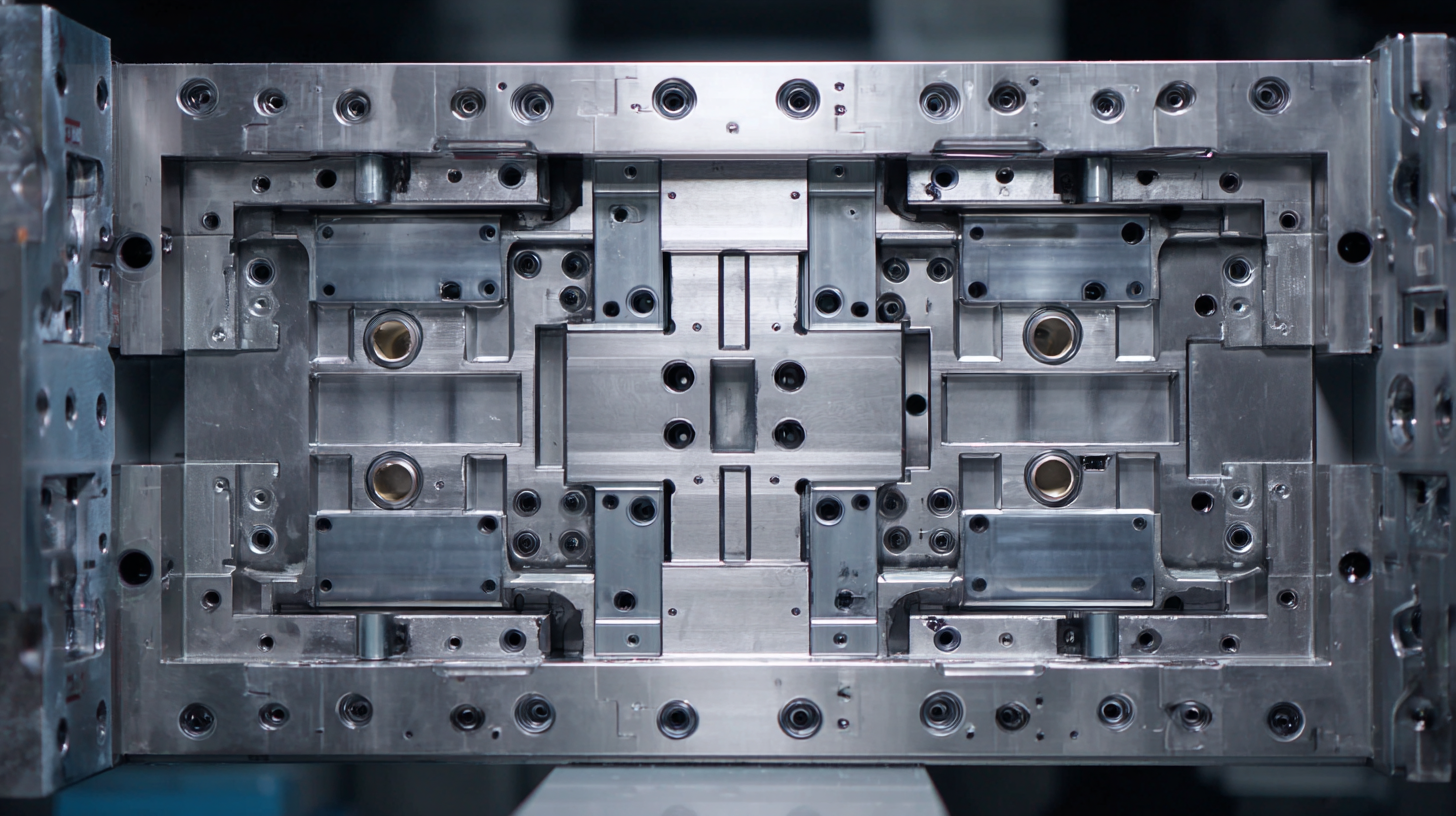

When selecting the right injection molding mold for your manufacturing needs, several key factors must be taken into account. First and foremost, the material of the mold is crucial; molds can be made from various metals, but the most common choices are steel and aluminum. Steel molds offer greater durability and longer lifespans, making them ideal for high-volume production, while aluminum molds are lighter and more cost-effective for low to medium production runs. Recent industry reports indicate that a well-constructed mold can significantly enhance production efficiency and reduce cycle times by up to 35%.

Another critical aspect is the design flexibility that modern technologies offer. The emergence of innovative manufacturing methods, such as a leading 3D printing approach that integrates seamlessly with traditional injection molding processes, allows for rapid prototyping and reduced lead times. This technology not only streamlines operations but can also minimize material waste, with some estimates suggesting that additive manufacturing can decrease waste by up to 50%. By considering these factors—material choice, production volume, and the integration of advanced technologies—manufacturers can make informed decisions when selecting the right injection molding mold to optimize their production capabilities.

When it comes to the design of injection molds, material selection plays a pivotal role, especially in the production of complex components like car door inner panels. Recent research emphasizes the importance of advanced composite materials, which not only enhance structural strength but also contribute to weight reduction. For instance, utilizing lightweight composites can reduce the overall weight of automotive components by up to 30%, thereby improving fuel efficiency and performance. Selecting the correct material can significantly impact the injection molding process, especially regarding flow characteristics and final part quality.

Moreover, the optimization of molding process parameters is essential to minimize issues like part warpage and injection pressure. Studies have shown that strategic choices regarding gate location can influence the flow of material and cooling rates, ultimately affecting the dimensional accuracy of the injection-molded parts. For example, a well-placed gate can lead to a 15% reduction in injection pressure while also decreasing part deflection during the cooling phase. This is particularly critical in intricate geometries, where even minor warpage can lead to significant manufacturing inefficiencies. By paying close attention to material selection and process parameter optimization, manufacturers can achieve superior results in the production of lightweight, high-performance automotive components.

| Material Type | Thermal Conductivity (W/mK) | Durability (Cycles) | Cost ($/kg) | Best Applications |

|---|---|---|---|---|

| Steel | 50 | 500,000 | 3.00 | Automotive parts, industrial components |

| Aluminum | 200 | 100,000 | 4.50 | Short runs, prototype molds |

| Copper | 400 | 300,000 | 8.00 | High-precision applications, complex geometries |

| P20 Tool Steel | 35 | 1,000,000 | 4.00 | Medium-volume production |

| H13 Tool Steel | 25 | 1,000,000 | 4.75 | High-volume production, wear-resistant needs |

When selecting an injection molding mold, avoiding common pitfalls can significantly enhance production efficiency and reduce costs. One of the most frequent mistakes is underestimating material compatibility. Choosing the wrong material can lead to increased scrap rates and production downtime. According to recent industry insights, improper material selection can result in up to 30% of operational inefficiencies. It’s imperative to analyze the physical and chemical properties of materials to ensure they align with the intended application.

Another critical mistake is neglecting the mold design aspects. Early identification and rectification of design deficiencies can save manufacturers substantial costs in the long run. Reports indicate that correcting design issues before production begins can enhance part quality and reduce the need for repairs by roughly 25%.

**Tips:** Always conduct a thorough assessment of material requirements and mold design specifications. Collaborate with design engineers to ensure that all potential issues are addressed during the initial stages. This proactive approach not only minimizes errors but also improves the overall manufacturing process. Moreover, staying updated on the latest methodologies for mold validation and redesign can further mitigate risks associated with injection molding operations.

When selecting an injection molding mold for your manufacturing requirements, evaluating the capabilities of mold manufacturers is crucial. According to a report by Grand View Research, the global molded plastics market is expected to reach $700 billion by 2025, underscoring the importance of choosing the right partner in a competitive landscape. Look for manufacturers with a proven track record in producing molds that meet the specific needs of your industry—whether it's automotive, consumer goods, or healthcare. A reliable manufacturer should demonstrate expertise in various materials, such as thermoplastics and thermosets, which can greatly influence the durability and performance of the final product.

Additionally, inquire about the manufacturer's technological capabilities. The adoption of advanced technologies, such as computer-aided design (CAD) and computer-aided manufacturing (CAM), can significantly enhance mold precision and reduce lead times. According to a 2021 report by ResearchAndMarkets, companies utilizing state-of-the-art manufacturing processes saw an improvement in production efficiency by up to 25%. It's also important to assess their quality assurance practices and ensure they adhere to relevant industry standards, such as ISO 9001, which can greatly impact the consistency and quality of your molds.