In the rapidly evolving landscape of manufacturing, the selection of appropriate injection molding equipment is a critical decision that can significantly impact production efficiency, product quality, and overall profitability. As reported by the Plastics Industry Association, the U.S. plastics industry alone contributes over $380 billion to the nation's GDP, emphasizing the importance of optimizing manufacturing processes. With the global injection molding market projected to reach $16.2 billion by 2026, manufacturers face increasing pressure to enhance their operational capabilities while minimizing costs.

Choosing the right injection molding equipment involves a comprehensive evaluation of various factors, including machine type, size, and technological advancements. According to research conducted by MarketsandMarkets, the injection molding machine market is expected to grow at a CAGR of 4.3% between 2021 and 2026, driven by the demand for lightweight and durable components across industries such as automotive, healthcare, and consumer goods. Manufacturers must stay informed about the latest innovations, such as hybrid and electric molding machines, which offer greater energy efficiency and precision compared to traditional hydraulic models.

Evaluating these options requires a thorough understanding of specific manufacturing needs and the capabilities of modern injection molding equipment. By leveraging industry insights and market data, manufacturers can make informed decisions that not only meet production demands but also align with long-term sustainability goals and competitive strategies.

When selecting injection molding equipment, manufacturers must carefully consider several key factors that can significantly influence their overall production efficiency and product quality. The existing market trends, such as the projected growth of the global micro injection molding machine market from $551.3 million in 2025 to $759.2 million by 2032, highlight the increasing demand for precise and compact solutions. This growth suggests manufacturers should prioritize advanced technology and innovative designs that offer flexibility and versatility to meet diverse client needs.

Another essential aspect of equipment selection is the impact of external factors such as tariffs on imported machinery and materials. The recent U.S. tariffs on imported plastics machinery, molds, and recycled resins can create short-term advantages for domestic manufacturers. However, these tariffs also raise long-term questions regarding supply chain stability and cost management. Manufacturers must evaluate the implications of such tariffs on their operational costs and strategic planning, ensuring they choose equipment that not only aligns with current industry demands but also withstands the evolving economic landscape.

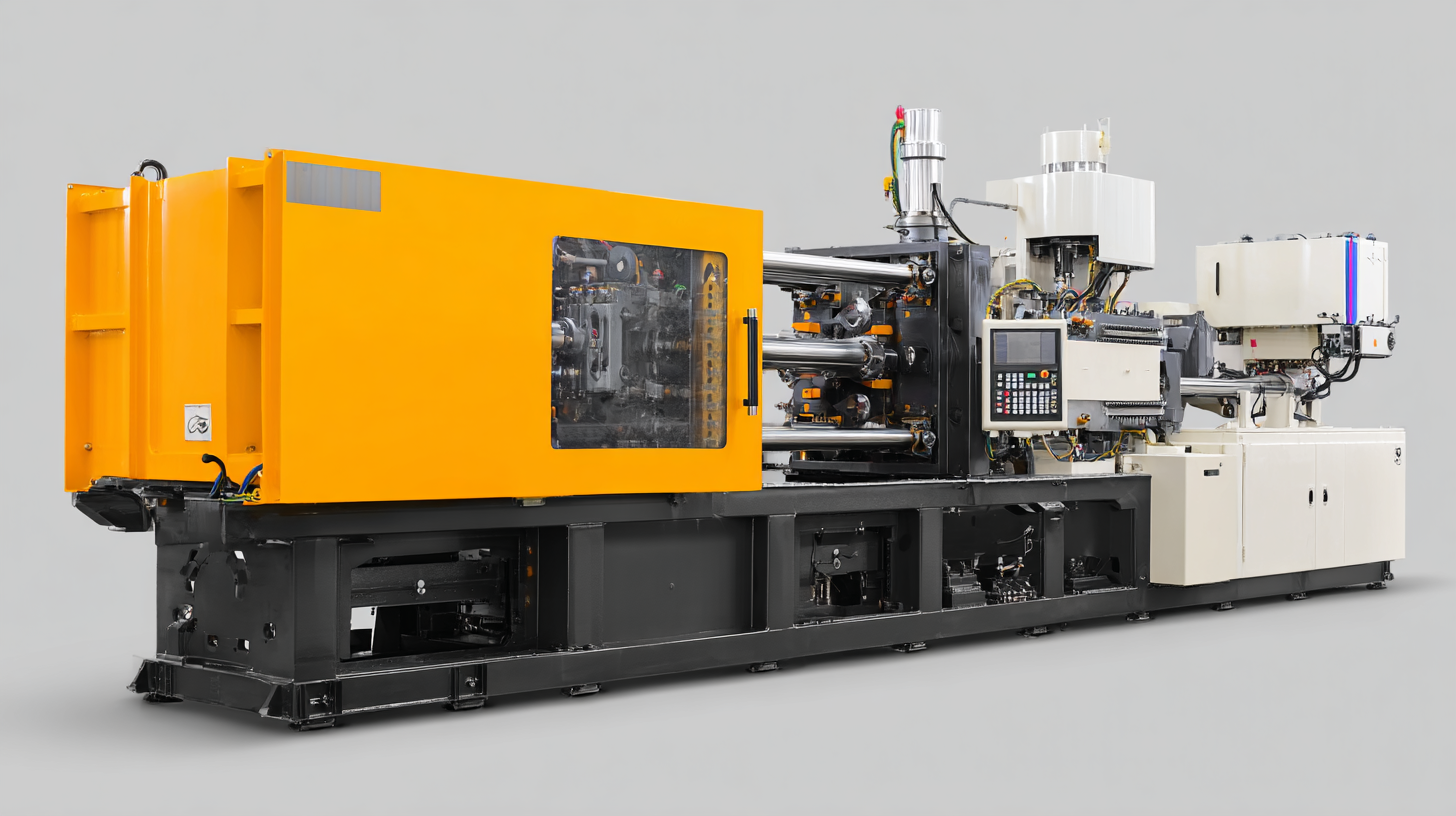

When choosing injection molding equipment, understanding the different types of injection molding machines and their applications is crucial for manufacturers. There are primarily three types of injection molding machines: hydraulic, electric, and hybrid.

Hydraulic machines, known for their robust performance, are commonly used for large parts and high-volume production due to their ability to maintain high clamping forces. In contrast, electric machines offer precision and energy efficiency, making them ideal for producing small, intricate components. Hybrid machines combine the advantages of hydraulic and electric technology, providing flexibility for various applications.

Hydraulic machines, known for their robust performance, are commonly used for large parts and high-volume production due to their ability to maintain high clamping forces. In contrast, electric machines offer precision and energy efficiency, making them ideal for producing small, intricate components. Hybrid machines combine the advantages of hydraulic and electric technology, providing flexibility for various applications.

The market for specialized injection molding technologies, such as micro injection molding and intelligent machines, is also on the rise. The micro injection molding market is projected to expand significantly, highlighting its importance in manufacturing small, precision parts used in medical devices and electronics. Additionally, the trend towards intelligent injection molding machines signifies a shift toward automation and connectivity, enhancing production efficiency. As sustainability becomes increasingly important, understanding the carbon footprint and energy consumption of these machines will guide manufacturers in making informed choices that align with eco-friendly practices.

When selecting injection molding equipment, manufacturers must first evaluate their specific production requirements, which include cycle times, tolerances, and material compatibility. Cycle times are critical as they directly affect productivity and efficiency. A thorough analysis of the desired production volume helps determine the optimal cycle time, ensuring that the chosen machinery can meet output demands without overburdening the system. The ability to achieve rapid cycle times often hinges on the machine's capabilities, such as injection speed and cooling efficiency, making these features essential considerations in the selection process.

Tolerances also play a significant role in equipment selection. The precision of the mold and machine must align with the specifications of the end product, as tighter tolerances necessitate more sophisticated machinery with advanced control systems. Manufacturers should assess their engineering requirements and quality standards to ensure that their chosen equipment can consistently produce parts within the desired specifications. Additionally, material compatibility is paramount; different plastics and composites require specific processing conditions. Understanding the thermal and mechanical properties of potential materials allows manufacturers to select equipment that can handle various polymers effectively, minimizing the risk of defects and costly production delays.

When considering the cost analysis of injection molding equipment, manufacturers must weigh the initial investment against long-term operational expenses. The initial costs include the price of the machinery, mold creation, and setup, which can represent a significant capital outlay for businesses. It is essential to choose reliable equipment that meets production demands without compromising quality, as this can lead to higher upfront expenses but potentially lower maintenance costs over time.

On the other hand, long-term operational expenses encompass energy consumption, material costs, and labor. Energy efficiency in machinery is critical; investing in advanced, energy-saving models can reduce operational costs significantly over the equipment's lifespan. Additionally, regular maintenance and repairs should be factored into the budget to maintain optimal performance and minimize downtime. By evaluating both the initial investment and expected operational expenses, manufacturers can make informed decisions that balance cost-effectiveness and production efficiency.

Recent advances in injection molding technology are significantly influencing equipment choices for manufacturers aiming for efficiency and sustainability. For instance, the incorporation of AI-driven capabilities in injection molding machines (IMMs) is revolutionizing production. According to industry reports, these technologies can enhance operational efficiency by up to 30%, reducing cycle times while improving product quality. As manufacturers face increasing pressure to minimize waste and enhance productivity, selecting the right equipment that integrates advanced technologies becomes essential.

In addition, the shift toward low-pressure injection molding presents a sustainable alternative that is reshaping traditional production techniques. This method not only lowers energy consumption but also minimizes material waste, aligning with the growing demand for environmentally responsible manufacturing practices. As observed, companies that adopt such innovations are better positioned to meet both regulatory requirements and consumer expectations for sustainable products. With the market projected to grow at a CAGR of 4.2% over the next five years, investing in modern injection molding equipment has become not just beneficial but necessary for manufacturers aiming to stay competitive in a rapidly evolving landscape.