Choosing the best injection molding equipment is crucial for businesses looking to optimize their manufacturing processes and enhance product quality. With advancements in technology and a competitive market landscape, selecting the right machinery can significantly impact operational efficiency and cost-effectiveness. Injection molding is a versatile method that offers the ability to produce complex and precise components across various industries, making the decision of equipment selection even more critical.

When considering injection molding equipment, businesses must evaluate several factors, including production volume, material compatibility, and the complexity of the parts being produced. The right equipment facilitates not only the production of high-quality products but also allows for scalability as business needs evolve. By understanding the distinct requirements of your operations and aligning them with the features of available equipment, you can ensure that your investment supports your long-term strategic goals. This guide aims to provide insights to help you navigate the choices and make informed decisions tailored to your unique business needs.

When it comes to selecting the best injection molding equipment for your business, understanding your specific business requirements is paramount. Different industries have varying needs based on the complexity of their products, production volume, and material types. For instance, a report by MarketsandMarkets predicts that the global injection molding market will reach approximately $363 billion by 2025, highlighting the increasing demand for efficient and versatile equipment. Businesses must assess their current workload and future production goals to determine the necessary capacity and capabilities of their injection molding machines.

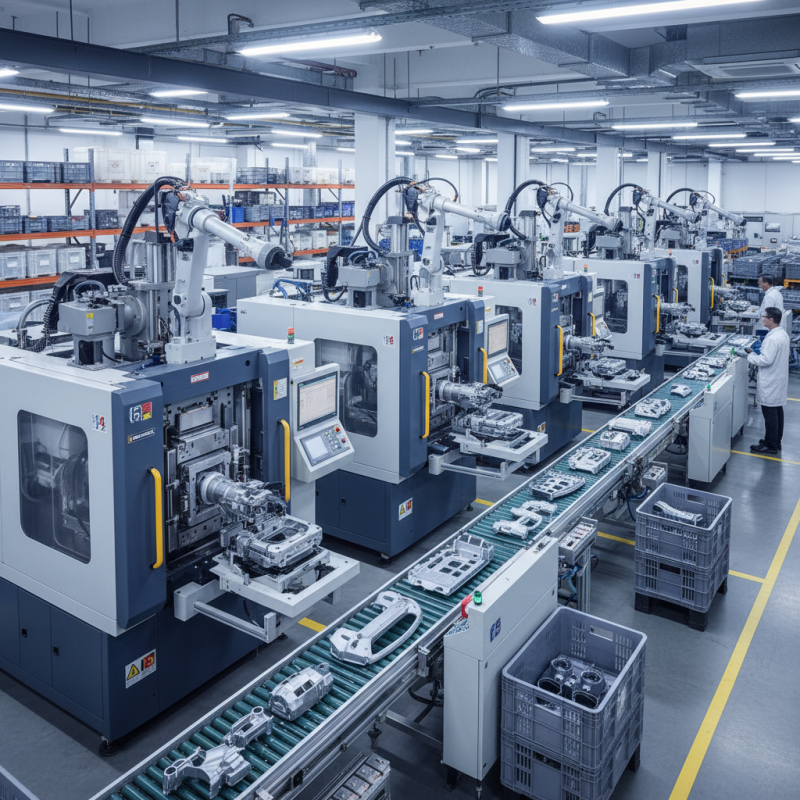

Moreover, the choice of equipment should align with material specifications. According to a study from the Plastic Industry Association, over 32% of plastic manufacturers highlighted the importance of compatibility with various resins, including thermoplastics and thermosets. Additionally, advanced features such as automation capabilities, energy efficiency, and ease of maintenance can significantly impact operational efficiency and cost-effectiveness. Therefore, businesses should conduct a thorough analysis of their product lifecycle, target market, and potential scalability before making the investment in injection molding machinery.

When selecting injection molding equipment for your business, it's essential to understand the various types available in the market. The most common types include hydraulic, electric, and hybrid injection molding machines. Hydraulic machines are prized for their power and versatility, making them suitable for large-scale production. Electric machines, on the other hand, offer precision and energy efficiency, leading to cost savings in long-term operations. Hybrid machines combine both technologies, providing a balance of power and energy efficiency which can be ideal for manufacturers with diverse production needs.

When considering which type of injection molding equipment to choose, it’s crucial to assess the specific requirements of your projects. For instance, if you prioritize precision and lower operational costs, electric machines might be the best fit. However, if you need to produce large quantities of parts quickly, hydraulic machines could serve your needs better.

Tips: Always evaluate your production volume and material types before making a decision. Furthermore, consider the ease of maintenance and availability of spare parts for each machine type. Consulting with industry professionals can provide additional insights tailored to your business requirements, ensuring you make an informed choice that aligns with your operational goals.

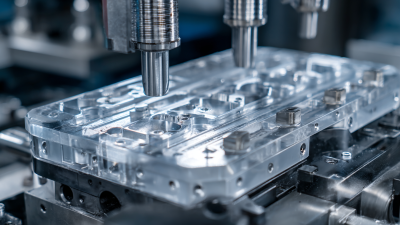

When selecting injection molding machinery, certain key features can greatly influence the efficiency and success of your production process. First and foremost, consider the clamping force of the machine, which must be appropriate for the materials you are working with and the size of your parts. According to industry reports, the optimal clamping force is often determined by the part's projected area and the material's viscosity; therefore, understanding your product specifications is crucial.

Another vital feature is the injection unit design. Machines with a balanced injection unit can provide more consistent material flow and better control over shot volume, ultimately leading to higher quality parts. Recent studies suggest that using machines with advanced injection systems can reduce cycle times by up to 20%, enhancing overall productivity. Additionally, consider the machine's adaptability to various materials, as versatility can lead to cost savings and a broader product range.

**Tips:** Look for machines with energy-efficient designs, such as servo-driven systems, which can reduce energy consumption by up to 50%. Also, ensure that the equipment allows for easy maintenance and has readily available technical support to minimize downtime. Investing in machinery with smart technology features can provide real-time monitoring and predictive maintenance alerts, further optimizing operational efficiency.

When selecting injection molding equipment, assessing your budget and cost-effectiveness is crucial. According to industry reports, manufacturers should expect the initial capital expenditure for high-quality injection molding machines to range from $50,000 to $250,000, depending on the complexity and capabilities required. Understanding your specific production needs will help you choose equipment that not only fits your budget but also aligns with your long-term business goals. Additionally, consider the operational costs, including maintenance, energy consumption, and the availability of spare parts, which can significantly impact your overall investment.

Tips for cost-effective equipment selection include evaluating the total cost of ownership (TCO) rather than just the purchase price. This involves calculating potential downtime, energy costs, and the efficiency of the machinery in relation to production output. Moreover, explore financing options or leasing programs that can mitigate upfront costs and provide flexibility in terms of budget management. Investing in energy-efficient machines can lead to substantial savings over time, as these models often consume 30% to 50% less energy compared to traditional equipment.

Lastly, it's essential to assess the scalability of your chosen equipment. As reported by industry analysts, businesses that plan for future growth by selecting modular systems that can be easily upgraded or expanded tend to maintain a competitive edge. Consider your production forecasts and choose equipment that not only meets your current needs but is also capable of adapting to future demand without a significant financial burden.

When selecting injection molding equipment for your business, evaluating the supplier's reputation and their after-sales support options is crucial. A recent industry report emphasizes that 60% of manufacturers consider after-sales service quality as a key factor in their purchasing decisions. A supplier's reputation can be gauged through customer reviews, testimonials, and industry recognition. Engaging with other businesses within your network can provide valuable insights into which suppliers consistently deliver on their promises.

Tip: Before finalizing your decision, make sure to check the supplier's track record for reliability. Look for partnerships that span several years and demonstrate consistent support.

After establishing a supplier’s reputation, it's essential to assess their after-sales support. Effective support can include training programs, 24/7 technical service, and comprehensive warranty policies. According to a survey conducted by a leading industry association, 75% of manufacturers reported that robust after-sales support significantly contributes to enhanced operational efficiency and reduced downtime. Ensure that potential suppliers offer clear and responsive communication channels to address any issues that may arise during your production processes.

Tip: Choose a supplier that not only provides equipment but also commits to ongoing training and upgrades, ensuring your team stays informed about the latest technologies and optimizations in injection molding.

| Supplier Name | Reputation Score (out of 10) | After-Sales Support Rating | Warranty Period | Lead Time (Weeks) |

|---|---|---|---|---|

| Supplier A | 9 | Excellent | 24 Months | 6 |

| Supplier B | 8 | Good | 18 Months | 8 |

| Supplier C | 7 | Fair | 12 Months | 5 |

| Supplier D | 9 | Outstanding | 36 Months | 10 |

| Supplier E | 6 | Satisfactory | 12 Months | 7 |