The injection machine industry is rapidly evolving, driven by advancements in technology and changing market demands. According to a recent report by Grand View Research, the global injection molding machine market is expected to reach $20.17 billion by 2026. This growth highlights the importance of choosing the right injection machine to meet specific business needs.

Industry expert Dr. Emily Zhang emphasizes, “Selecting the appropriate injection machine can significantly improve production efficiency.” Her insights underline the necessity for businesses to align equipment choices with their operational goals. As companies navigate their options, there are numerous factors to consider, from machine size to energy efficiency.

Making informed decisions can be challenging. Each company has unique requirements, shaping the type of injection machine suited for their applications. Recognizing potential pitfalls is essential. Many overlook maintenance costs or future scalability, which could impact long-term success. Thorough research and expert advice are critical for optimal choices in this competitive landscape.

In 2026, the landscape of injection machines continues to evolve. Different types cater to various production needs. Understanding these options is crucial for making informed decisions. The global injection molding machine market is projected to reach $15 billion by 2027, growing annually at 5.5%. This growth highlights the importance of selecting the right machine.

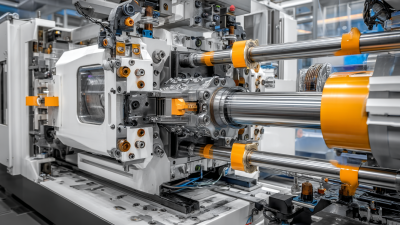

Hydraulic injection machines dominate the market, providing power and reliability for larger-scale operations. They excel in producing heavy parts. On the other hand, electric machines are gaining traction due to their energy efficiency and precision. They are ideal for high-demand production with lower cycles. According to industry reports, electric machines reduce energy consumption by up to 70%.

Hybrid machines combine both hydraulic and electric technologies. They offer flexibility and efficiency. However, choosing the right machine demands careful assessment of your production needs. Factors such as material type, part complexity, and production volume play a significant role. Many businesses struggle here, often underestimating the importance of precise requirements. Investing time in understanding these factors can lead to better long-term results.

| Machine Type | Clamping Force (tons) | Injection Volume (cm³) | Cycle Time (seconds) | Energy Efficiency | Application |

|---|---|---|---|---|---|

| Hydraulic Injection Machine | 50 - 200 | 100 - 800 | 20 - 30 | Moderate | General Purpose |

| Electric Injection Machine | 20 - 250 | 50 - 1000 | 10 - 15 | High | Precision Parts |

| Multi-component Injection Machine | 80 - 300 | 200 - 600 | 25 - 40 | Moderate to Low | Complex Geometries |

| Gas-assist Injection Machine | 60 - 280 | 150 - 900 | 15 - 25 | High | Thin-Walled Parts |

When assessing your production needs for selecting an injection machine, it’s crucial to analyze your capacity requirements. According to industry reports, the global market for injection molding machines is expected to reach $12 billion by 2026. This growth indicates increased demand. Therefore, understanding your specific production volume is key.

Start by defining your annual output. For many manufacturers, a production rate of 100,000 units can be a good benchmark. If you need higher volumes, consider machines with larger clamping forces. A 1500-ton press, for example, typically handles heavy-duty applications efficiently. Remember, not every machine fits every need.

**Tip:** Assess both current and future needs. A machine suitable for today may not meet demands in three years.

Energy efficiency is another important aspect. Reports show that machines with improved energy consumption can cut costs by up to 30%. Look at specifications and consider sustainability in your choices. Understanding these details minimizes the risk of over or under-investing.

**Tip:** Calculate your total cost of ownership, including energy and maintenance.

Don't overlook the importance of adaptability. Some machines can be retrofitted or upgraded. Future-proofing ensures your investment serves you well as production needs evolve.

This chart illustrates the estimated production capacity of different types of injection machines based on their specifications and expected usage in 2026. The data highlights the average production capacity (units per hour) for various machine types commonly used in manufacturing industries.

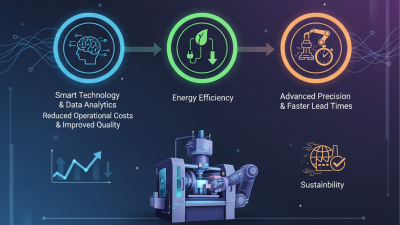

When selecting an injection machine in 2026, consider key features that can enhance performance. Look for energy efficiency, as modern machines consume less power. This feature can significantly lower operational costs over time. Advanced precision systems are also essential. They ensure that every injection is uniform, reducing waste. Precision matters more than ever in competitive markets.

Another critical aspect to consider is the control system. Opt for machines with user-friendly interfaces. A good interface simplifies operation and reduces training time. However, keep in mind that complex systems may require ongoing maintenance. It's vital to weigh benefits against potential challenges. Additionally, flexibility in production options is crucial. Machines that can handle various materials will give you an edge. Think about future needs as well.

Don't overlook the importance of support and service. Reliable technical support is invaluable. Machines will inevitably face issues, and quick resolution matters. This helps maintain consistent productivity. Ultimately, investing in the right features can be tricky. Reflect on your specific needs carefully before making a decision. This ensures that your choice aligns with both current demands and future growth.

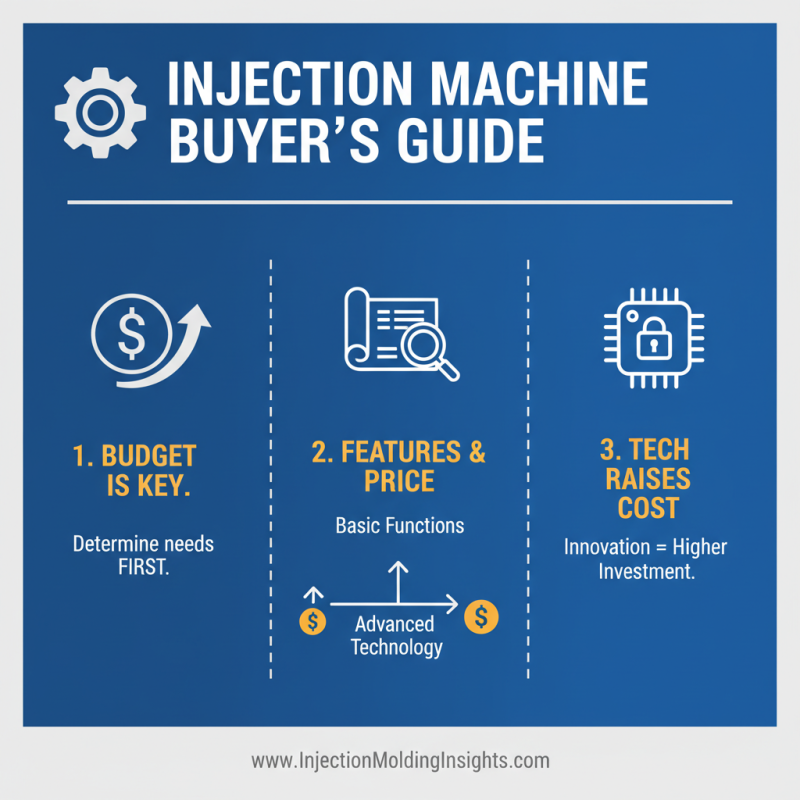

When evaluating injection machines, budget is critical. Determine your needs before making any decisions. A machine's price is influenced by features. Basic functions may cost less. However, advanced technology will raise the price significantly.

It's essential to assess long-term value. Cheaper options may lead to higher maintenance costs. Consider energy efficiency as well. Some machines consume more energy, impacting operating costs.

Think about financing options too. Upfront costs can be daunting. Leasing might ease the initial burden. Reflect on the potential return on investment. Investing wisely today can yield savings tomorrow. Always weigh the pros and cons carefully before settling on a choice.

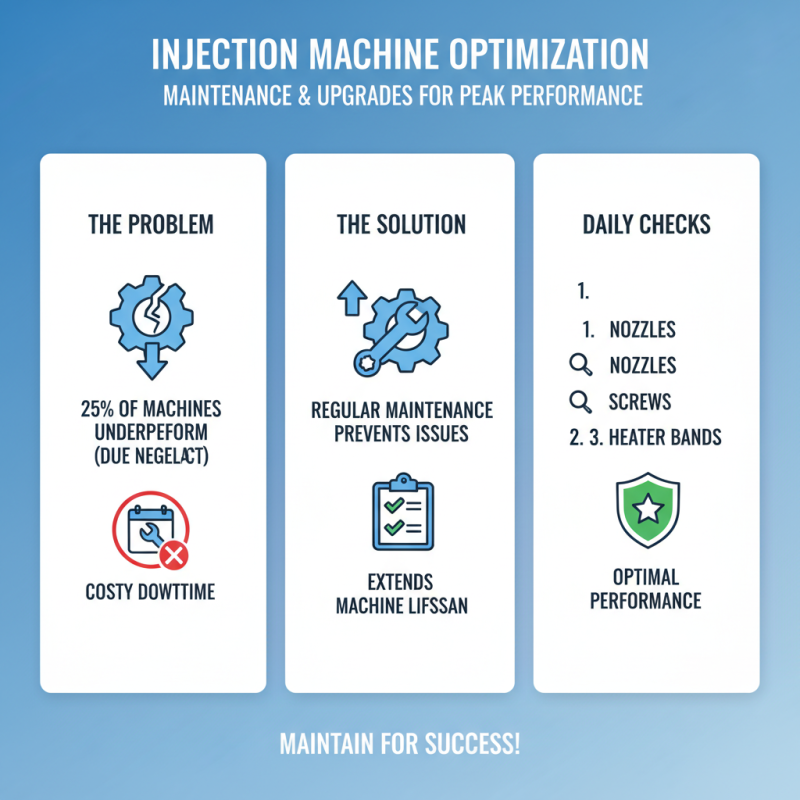

Maintaining and upgrading injection machines is crucial for optimal performance. Industry reports indicate that around 25% of injection machines operate below their full potential due to neglect. Regular maintenance can prevent this issue. Daily checks of key components can extend the life of the machine significantly. It involves inspecting nozzles, screws, and heater bands. Some operators overlook these simple tasks, leading to costly downtimes.

Upgrading technology is another key factor. Machines typically have a lifespan of 10 to 15 years. After that, performance can decline rapidly. Upgrading software or adding features can boost efficiency. Data suggests that companies implementing upgrades saw a productivity increase of up to 30%. Despite this, many hesitate. They fear the initial cost, underestimating the long-term savings. Changing the mindset around these investments is essential for success.

Making small adjustments often yields better results than major overhauls. Continuous training for operators cannot be ignored. Knowledge gaps can lead to mismanagement. It's vital to regularly assess both the machines and the personnel. Improved practices should evolve with new insights from the industry. Small steps toward enhancement can lead to significant benefits.