Thermoplastic injection molding has become a cornerstone in modern manufacturing, delivering unmatched advantages in efficiency, precision, and sustainability. According to a recent report by the International Plastics Manufacturers Association, the thermoplastic injection molding market is projected to reach $300 billion by 2025, highlighting the pervasive reliance on this technology across industries. The ability to produce complex geometries and intricate designs with minimal waste has solidified its reputation as a preferred method for large-scale production.

Expert insights into this innovative process underscore its significance. Dr. Sarah Thompson, a leading expert in polymer engineering, states, "Thermoplastic injection molding not only optimizes production cycles but also significantly enhances the recyclability of plastic products, reflecting the industry's shift towards sustainability." This emphasizes that the integration of thermoplastic materials not only meets the demands of the market but also aligns with contemporary ecological standards. As manufacturers increasingly look for solutions that combine cost-effectiveness with environmental responsibility, thermoplastic injection molding stands out as a viable and forward-thinking option for their production needs.

Thermoplastic injection molding has become a preferred choice for many manufacturers due to its numerous advantages in production efficiency and material versatility. One significant benefit of this method is its ability to produce complex shapes with high precision. According to a report by the Society of Plastics Engineers, thermoplastic injection molding can achieve tolerances of ±0.01 mm, which is critical for industries that require high-quality components, such as automotive and aerospace. Furthermore, the rapid cycle times associated with this process can lead to increased productivity, as molds can be produced at a speed of up to 100 cycles per hour, allowing for large quantities of parts to be manufactured quickly.

Additionally, thermoplastic materials offer excellent recyclability, promoting sustainable manufacturing practices. Research from the American Chemical Society indicates that nearly 70% of thermoplastic materials can be recycled, reducing waste and lowering material costs in the long run. This eco-friendly aspect not only meets the growing demand for sustainable practices among consumers but also helps companies adhere to stringent environmental regulations.

Tips: When considering thermoplastic injection molding for your projects, it is essential to assess the specific thermoplastic material's properties to ensure it meets your performance requirements. Additionally, investing in high-quality molds and machinery can significantly impact the efficiency and quality of your production process. Regular maintenance of equipment can also optimize operation and extend the life of your molds.

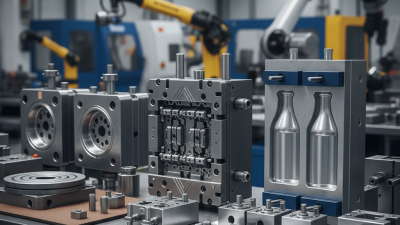

Thermoplastic injection molding has established itself as a cornerstone across various industries due to its versatility and efficiency. This manufacturing process is particularly advantageous for producing intricate parts in sectors like automotive, electronics, medical devices, and consumer goods. According to a recent study by Grand View Research, the global thermoplastic injection molding market was valued at approximately $30 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of about 5.6% from 2023 to 2030. This growth is driven by the increasing demand for lightweight and durable components, especially in industries focused on sustainability and innovation.

In the automotive industry, thermoplastic injection molding is utilized extensively to create lightweight parts that improve fuel efficiency while maintaining safety standards. For instance, components such as dashboard panels and housing for electronic systems are often produced using this technique. Similarly, in the medical sector, the ability to produce precise and hygienic parts—like syringes and surgical instruments—affirms the technology’s role in fostering advancements in healthcare. Additionally, as reported by MarketsandMarkets, the consumer goods sector is rapidly adopting thermoplastic injection molding, projected to experience substantial growth driven by converting ideas into market-ready products quickly and cost-effectively. This highlights the process's significance and adaptability across diverse applications and industries.

| Industry | Key Applications | Materials Used | Benefits |

|---|---|---|---|

| Automotive | Dashboard components, fuel tanks, and exterior trims | ABS, Polypropylene, and Nylon | Lightweight, cost-effective, and durable |

| Consumer Goods | Kitchenware, toys, and packaging | Polyethylene, Polypropylene, and Polystyrene | Versatile designs, high production speed, and recyclability |

| Medical | Syringes, IV connectors, and surgical instruments | Polycarbonate, Polypropylene, and PEEK | Biocompatibility and precision manufacturing |

| Electronics | Casings, connectors, and insulators | ABS, Polycarbonate, and PBT | Electrical insulation and heat resistance |

| Aerospace | Interior components and lightweight structures | Nylon, PEEK, and Carbon Fiber Reinforced Polymers | Weight reduction and superior mechanical properties |

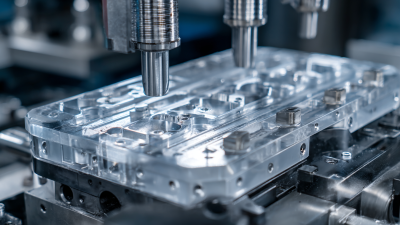

Thermoplastic injection molding is a highly efficient manufacturing process that involves the heating of thermoplastic materials until they become pliable, followed by injecting them into a mold to create intricate parts. This method offers significant advantages in terms of precision and repeatability, making it ideal for producing high-quality components in various industries. The process begins with the selection of the appropriate thermoplastic resin, which is then melted and injected into a mold under high pressure, allowing it to fill even the most complex cavities.

Once the material cools and solidifies, the final product is ejected from the mold, ready for use or further processing. This versatility allows manufacturers to produce a wide range of parts, from automotive components to consumer goods. Additionally, thermoplastic injection molding supports rapid production cycles, facilitating faster time-to-market for new products. By understanding the mechanics of this process, manufacturers can leverage its benefits, optimizing their operations for efficiency and cost-effectiveness while maintaining high product quality.

Thermoplastic injection molding is renowned for its material versatility, making it a favored choice for manufacturers across various sectors. One of the primary advantages of this process is the wide range of thermoplastic materials available, each with distinctive properties suitable for different applications. From polycarbonate's high impact resistance to polypropylene's lightweight nature, the variety allows manufacturers to select the most appropriate material for their specific needs. This flexibility not only enhances product performance but also optimizes production efficiency, enabling a diverse range of applications from automotive parts to consumer goods.

Moreover, the ability to blend different thermoplastics opens even more possibilities for customization. Manufacturers can create composite materials that leverage the strengths of multiple thermoplastics, resulting in products that are both performance-oriented and cost-effective. This adaptability in material selection also facilitates recycling initiatives, as many thermoplastics can be reused and remolded. As sustainability becomes a priority in manufacturing, the ability to choose eco-friendly thermoplastics further enhances the appeal of injection molding, permitting companies to meet both market demands and regulatory standards while maintaining high quality and structural integrity in their products.

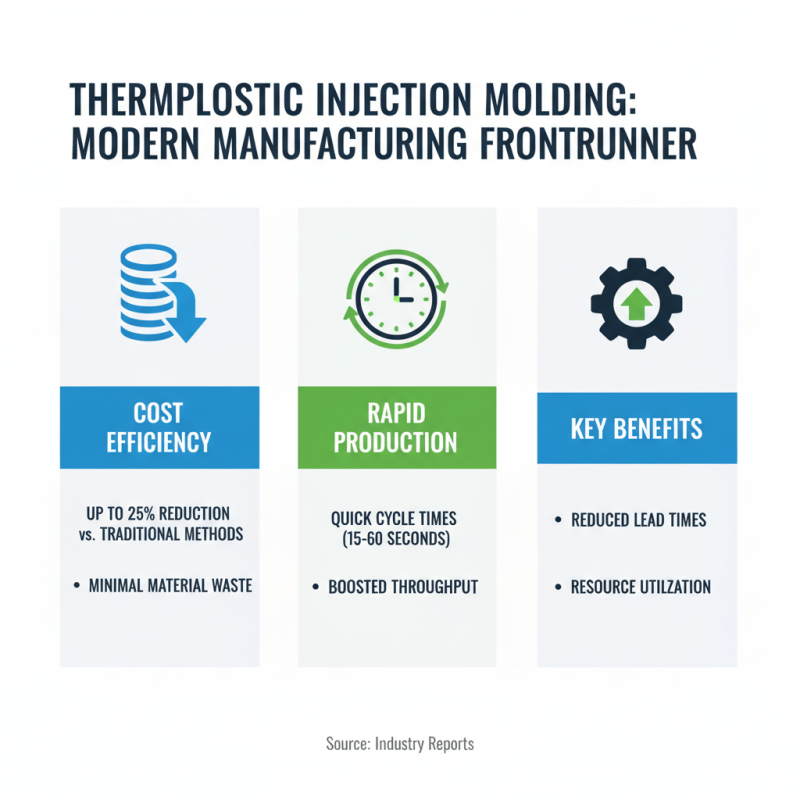

Thermoplastic injection molding has emerged as a frontrunner in modern manufacturing, primarily due to its exceptional cost efficiency and rapid production capabilities. According to industry reports, companies adopting this method can reduce production costs by up to 25% compared to traditional manufacturing processes. This efficiency is largely attributed to the minimal material waste that thermoplastic injection molding offers, enabling manufacturers to use resources more effectively. Furthermore, the quick cycle times associated with this method, often averaging between 15 to 60 seconds per cycle depending on part complexity, significantly boost throughput and reduce lead times.

In addition to cost savings and speed, thermoplastic injection molding facilitates high-volume production without compromising quality. Industry standards indicate that the process can maintain tolerances as tight as ±0.001 inches, making it ideal for precision-engineered components. This blend of efficiency and quality allows manufacturers to respond quickly to market demands, increasing their competitiveness. The ability to produce large quantities over short periods means that businesses can more efficiently scale up operations, meeting consumer needs without the burden of extensive inventory costs. As the manufacturing landscape continues to evolve, thermoplastic injection molding stands out as a strategic choice for companies looking to optimize both their budget and output.