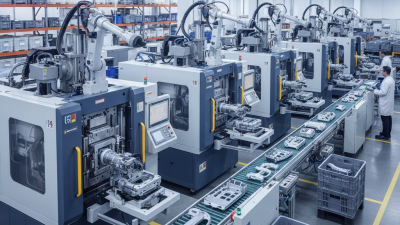

Choosing the right injection molding machine is a crucial decision for any manufacturing business aiming to optimize production efficiency and maintain product quality. Injection molding machines are the backbone of plastic production, facilitating the creation of intricate designs and durable parts. With a variety of options available in the market, understanding your specific business needs is essential to make an informed selection.

The choice of an injection molding machine depends on several factors, including the type of materials being used, the complexity of the parts being produced, and production volume requirements. Businesses must assess the technological capabilities of different machines, such as their clamping force, cycle time, and energy efficiency, to ensure they meet both current and future production demands. By carefully evaluating these aspects, manufacturers can streamline their operations and enhance their overall productivity.

Ultimately, investing in the right injection molding machine can lead to significant cost savings and improved product consistency. This guide will explore key considerations and steps to help you identify the most suitable machine tailored to your unique business operations, paving the way for sustained growth and success in the competitive landscape of manufacturing.

Understanding injection molding is essential for businesses looking to produce high-quality plastic parts efficiently.

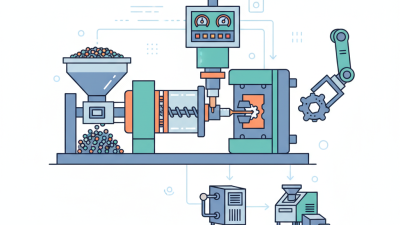

At its core, injection molding involves injecting molten plastic into a mold to create desired shapes. This process is highly valued for its ability to produce complex geometries with tight tolerances, which is vital in industries such as automotive and consumer electronics. According to a report from MarketWatch, the global injection molding market is projected to reach $432.8 billion by 2027, highlighting the increasing demand for this manufacturing method across various sectors.

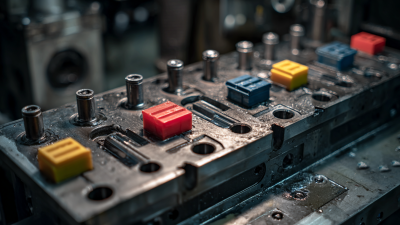

When selecting an injection molding machine, it’s crucial to understand key terminology. The tonnage of a machine, which refers to the clamping force it can exert, is one of the critical specifications to consider. For instance, a machine with too low a tonnage may fail to hold the mold securely, leading to defects in the final product. Additionally, cycle time—the duration required for the entire injection molding process from filling to cooling—directly impacts production efficiency. Manufacturers are looking to minimize cycle time to enhance output; studies indicate that optimizing machine settings can reduce cycle time by up to 25%.

Tips for businesses: First, always assess your production volume needs when choosing a machine size and tonnage. Second, familiarize yourself with the different types of molds available, such as single-cavity versus multi-cavity molds, as they greatly affect production efficiency and cost. Finally, consider investing in advanced features like automation and monitoring systems, which can significantly streamline operations and ensure consistent quality.

When selecting the right injection molding machine, a thorough assessment of production requirements and business goals is essential. Understanding your production volume needs is the first step; manufacturers should analyze their current and projected outputs. According to a report by the Plastics Industry Association, the demand for custom plastic products has grown by approximately 4% annually. This growth necessitates machinery that can adapt to varying production scales, accommodating both small batch runs and large-volume outputs effectively.

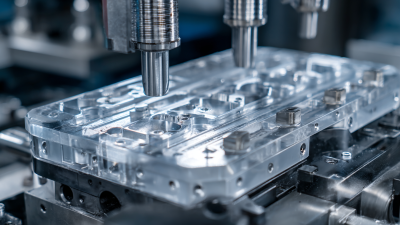

In addition to volume, identifying the intricacies of your product designs is crucial. Complex geometries may require machines with advanced capabilities such as multi-material processing or precise temperature control. The research published by Mordor Intelligence indicates that the injection molding market is projected to reach USD 347 billion by 2025, highlighting the importance of utilizing machinery that not only meets current production goals but is also future-ready for evolving market demands. This foresight can significantly impact operational efficiency and product quality, leading to enhanced competitiveness in an ever-evolving industry.

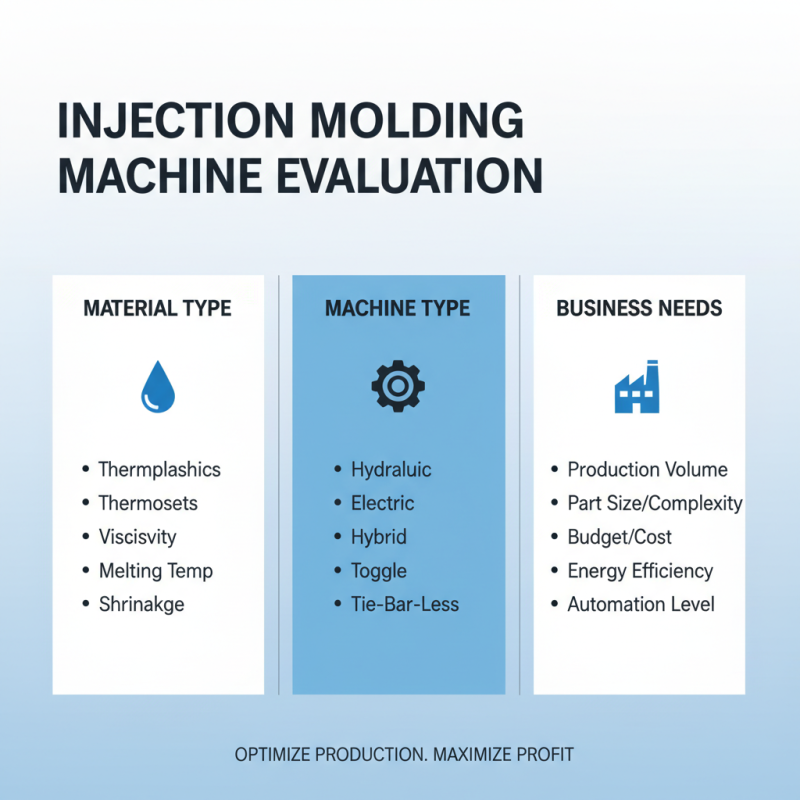

When evaluating different types of injection molding machines, it’s essential to consider several factors that align with your business requirements. First, assess the type of materials you will be using, as different machines have varying capabilities in handling specific thermoplastics and thermosetting plastics. Understanding the viscosity, melting temperature, and shrinkage properties of your materials can guide you toward the right machine type that ensures optimal processing.

Another crucial factor is the machine's configuration. Injection molding machines typically fall into three categories: horizontal, vertical, and specialty types. Horizontal machines are the most common and suitable for a wide range of applications, while vertical machines are ideal for insert molding and save space in the shop floor. Specialty machines cater to specific needs, such as multi-material injection. Choosing the right configuration involves considering the space you have and the complexity of the parts you intend to produce.

**Tips:** Prioritize machines with a robust control system to enhance precision and efficiency. Additionally, consider the machine's energy consumption; energy-efficient models can save substantial operational costs in the long run. Lastly, ensure that maintenance support is accessible and that the machine has a solid service record to avoid unexpected downtimes. Selecting the right injection molding machine involves balancing your production needs with these critical factors, leading to more effective manufacturing processes.

When selecting the right injection molding machine, understanding machine specifications such as size, capacity, and power is crucial for ensuring it meets your business needs. The size of the machine not only influences the types of molds you can use but also impacts the production floor space required. For instance, a report by the Plastics Industry Association indicates that medium to large machines (1000-3000 tons) dominate the market, catering to manufacturers that require robust capacity for larger products. Conversely, smaller machines (20-200 tons) are more suitable for specialized or smaller-scale production runs, offering flexibility and reduced overhead.

Capacity and power are equally important aspects of your decision-making. The capacity of an injection molding machine determines the volume of plastic that can be processed at a time, essential for meeting productivity demands. According to a recent market analysis, an increasing number of manufacturers are opting for machines with energy-efficient designs that consume less power while maintaining optimal performance. Such machines can reduce production costs significantly, allowing businesses to operate within tighter margins without compromising quality.

**Tip:** Always calculate your production volume needs against the machine's capacity to avoid bottlenecks in your manufacturing process.

Also, consider the total power consumption of the machine; investing in energy-efficient models can lead to long-term savings on operational costs. As the industry shifts toward sustainability, choosing a machine that balances power and performance can provide a competitive edge while aligning with eco-friendly practices.

| Machine Model | Size (mm) | Clamping Force (tons) | Injection Capacity (g) | Power Consumption (kW) |

|---|---|---|---|---|

| Model A | 3500 x 1600 x 2000 | 120 | 500 | 15 |

| Model B | 4000 x 1800 x 2200 | 150 | 700 | 20 |

| Model C | 4500 x 2000 x 2500 | 200 | 900 | 25 |

When choosing the right injection molding machine, understanding the budget considerations and total cost of ownership (TCO) is crucial for any business. According to a report by the Plastics Industry Association, the average cost of an injection molding machine can range from $10,000 to over $300,000, depending on the machine's capabilities and specifications. This initial outlay is only the beginning, as businesses must also consider operational costs, maintenance, and potential downtime, which can significantly impact the TCO.

Maintenance can account for up to 20% of the TCO over a machine's lifespan. Regular servicing and replacement parts can add up quickly, and businesses should budget for these expenses accordingly. Furthermore, energy consumption is another major cost factor. The Energy Department has indicated that injection molding machines can consume a substantial amount of power, with newer, energy-efficient models providing savings of 30% or more compared to older machines. This highlights the importance of evaluating energy efficiency when making a purchasing decision, as it can lead to significant savings over time.

Finally, businesses must consider the expected lifecycle and resale value of the machine. Industry analysis suggests that well-maintained injection molding machines can retain about 50%-70% of their original value after five years. This factor should be part of the financial calculations when determining the total cost of ownership, as it can influence cash flow and reinvestment strategies. A comprehensive understanding of these cost considerations will enable businesses to make informed decisions that align with both their operational needs and financial goals.