In the ever-evolving landscape of manufacturing, the role of

machine molds has become increasingly vital for enhancing

efficiency and productivity. As the industry progresses, understanding the

top machine molds that excel in performance is crucial for manufacturers

looking to stay competitive. According to industry expert Dr. Emily Chang, a leading authority on

manufacturing technologies, "The right machine mold can significantly reduce

production time and improve product consistency, making it an indispensable asset in modern manufacturing."

In this comprehensive overview, we will explore the ten best machine molds that have proven to maximize efficiency in manufacturing processes. Each selection will reflect advancements in design, materials, and technology that lead to better operational outcomes. As we dive deeper, we will highlight the characteristics that distinguish these machine molds, providing insights for manufacturers aiming to enhance their production capabilities and ensure long-term success in an increasingly competitive market.

Stay with us as we unveil the top five contenders in the realm of machine molds for 2025, setting the groundwork for future innovations and operational excellence. By prioritizing efficiency and quality, these machine molds are not just tools but pivotal components that redefine the manufacturing landscape.

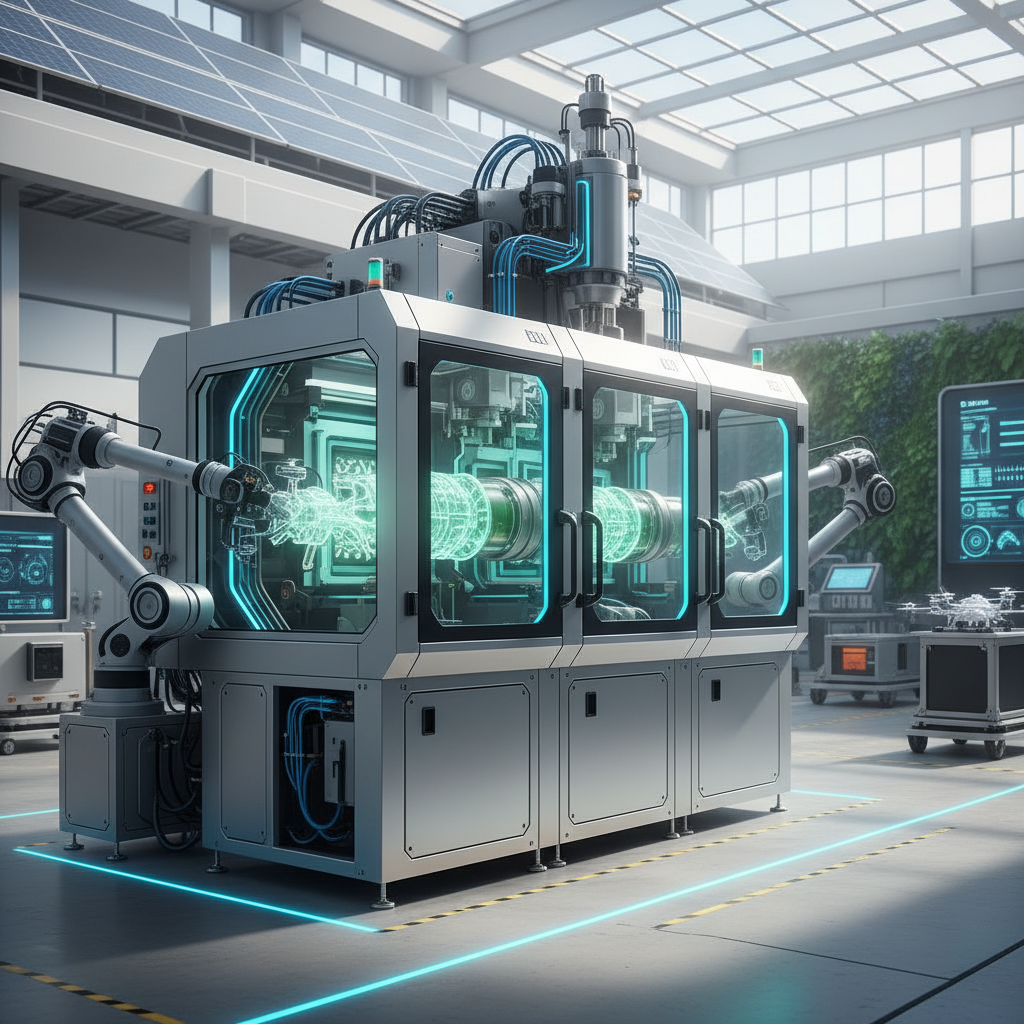

As we move toward 2025, manufacturing efficiency is being revolutionized by advanced technologies such as AI, IoT, blockchain, and robotics. These innovations support Packaging 4.0 by enhancing productivity and sustainability across the manufacturing landscape. For instance, AI enables predictive maintenance and real-time monitoring, leading to reduced downtime and improved operational efficiency. IoT devices facilitate seamless communication between production equipment, optimizing workflows and ensuring timely responses to changes in demand.

In addition to these technologies, the integration of robotics is reshaping the manufacturing process, particularly in plastics manufacturing. Collaborative robots (cobots) enhance precision and safety while allowing for greater flexibility on the production line. As these technologies continue to evolve, they are setting the stage for smarter, more efficient manufacturing processes that prioritize sustainability.

Tips: To stay ahead in the evolving manufacturing landscape, consider investing in training for your staff on the latest technologies. Implementing a phased approach to integrating AI and robotics can help manage costs and improve adoption rates. Lastly, regularly assess your production processes to identify potential areas for efficiency improvements, ensuring you remain competitive in the market.

The use of advanced materials in the production of machine molds has significantly enhanced durability and performance, ultimately driving efficiency in manufacturing processes. Modern materials such as composite polymers and high-performance metals are engineered to withstand extreme conditions, reducing wear and tear during production. These materials not only prolong the lifespan of molds but also minimize maintenance costs, ensuring that manufacturing operations remain uninterrupted and efficient.

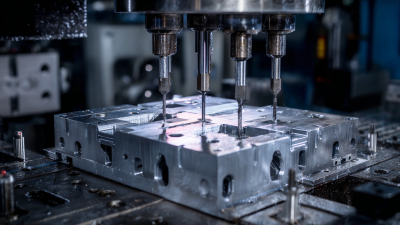

Moreover, the adoption of advanced manufacturing techniques, including 3D printing and CNC machining, complements the benefits of innovative materials. These technologies enable the creation of complex mold designs that are both lightweight and structurally sound. The intricacies achievable through advanced materials allow for improved heat resistance and lower friction, which contribute to faster cycle times and better product consistency.

As manufacturers continue to invest in state-of-the-art materials and techniques, the overall effectiveness of machine molds will likely see substantial improvements, powering the next generation of efficient manufacturing systems.

Injection molding and blow molding are two dominant manufacturing processes in the production of plastic components, each excelling in different aspects of efficiency. According to a report by the Plastics Industry Association, injection molding often achieves cycle times as low as 15-30 seconds per part, which significantly enhances productivity in high-volume applications. This rapid cycle time, combined with the ability to produce complex geometries with tight tolerances, makes injection molding particularly favorable for items like consumer electronics housings and automotive components.

On the other hand, blow molding showcases its efficiency in producing hollow objects, such as bottles and containers, while also incorporating materials with minimum excess. The Society of the Plastics Industry indicates that blow molding can reach production rates of up to 300 units per hour, depending on the machine type and design complexity. While the initial setup for blow molding can be more time-consuming compared to injection molding, its material efficiency and lower scrap rates contribute to significant cost savings in large-scale production environments. As manufacturers aim for maximum efficiency, the choice between injection molding and blow molding will ultimately depend on the specific product requirements and production goals.

As we look towards the next decade, the design and functionality of machine molds are set to undergo profound transformations driven by technological innovations. The injection molding machines segment, which is projected to be valued at USD 830.9 million by 2025, is indicative of the broader industry's shift towards efficiency and sustainability, with a compound annual growth rate (CAGR) of 8.0% expected. Innovations such as low-pressure injection molding are redefined manufacturing processes, allowing for reduced material waste and improved energy efficiency, crucial in today’s environmentally-conscious landscape.

Moreover, advancements in automation and artificial intelligence are reshaping manufacturing paradigms, particularly in the plastics sector. The move towards Industry 4.0 emphasizes the integration of digital intelligence and smart automation into production lines, providing manufacturers with the ability to optimize operations continuously. The anticipated growth of the 3D printing industry, projected to surpass $40 billion by 2030, further highlights the significant role of these technologies in enhancing the precision and adaptability of machine molds. As manufacturers embrace these trends, the machine mold design will not only focus on functionality but also on meeting the sustainability demands of the future.

When evaluating machine mold efficiency in manufacturing, several key performance indicators (KPIs) can serve as benchmarks. One critical KPI is the cycle time, which measures the duration of one complete production cycle from start to finish. According to a 2022 report by the Manufacturing Institute, reducing cycle time by just 10% can lead to an overall increase in production efficiency of up to 25%. This improvement is vital for maintaining competitive advantage in the rapid-paced manufacturing environment.

Another important KPI is mold wear rate, which indicates how quickly a mold reaches the end of its useful life. Industry standards suggest that molds exhibiting a wear rate of less than 0.5% per 1,000 cycles are considered efficient. Tracking this metric closely allows manufacturers to schedule timely maintenance and reduce unexpected downtime. Additionally, the rate of defects produced per batch is crucial; a report from the Society of Manufacturing Engineers found that companies maintaining defect rates below 1% achieve significant cost savings and customer satisfaction improvements. By focusing on these KPIs, manufacturers can better assess their machine molds' performance and optimize their production processes.