In today’s fast-paced manufacturing landscape, understanding the best injection molding products is crucial. As industry expert John Anderson states, "Quality and efficiency define the best injection molding products." With advancements in technology, products range from intricate automotive parts to everyday consumer goods.

However, not every product on the market meets high standards. Some boast impressive features but may lack durability. Companies often prioritize cost over quality, leading to subpar results. It’s worth considering which injection molding products truly stand out in performance and reliability.

Evaluating products demands careful thought. Look for those that have proven track records. Often, success stories highlight specific use cases and customer satisfaction. The best injection molding products not only fulfill a function but also inspire innovation and excellence.

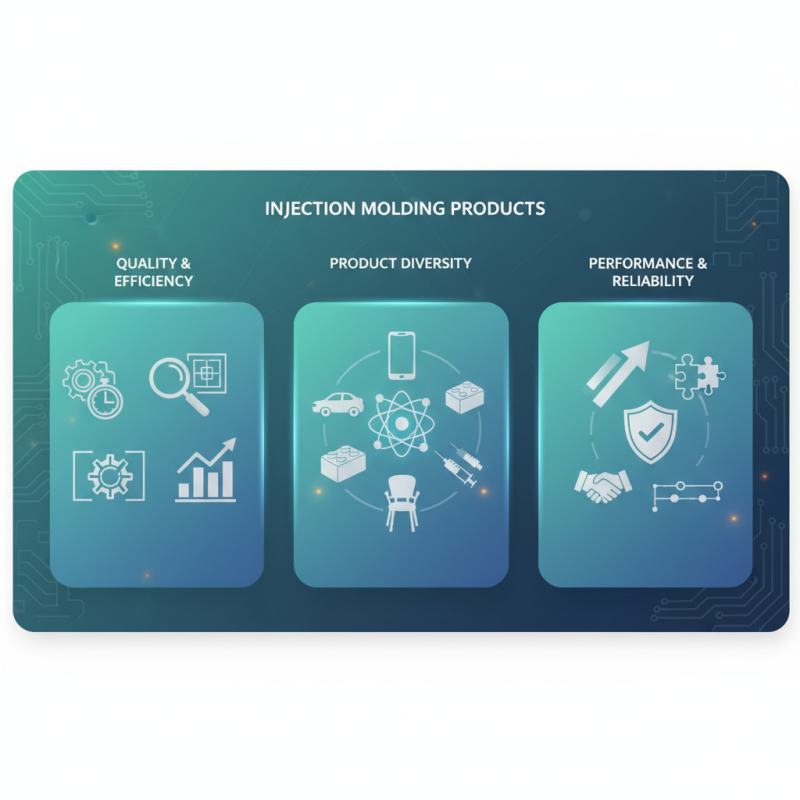

Injection molding is a widely used manufacturing process. It transforms raw plastic into intricate shapes. This technique is essential in various industries, from automotive to consumer goods. The process begins with heating plastic pellets until they melt. The molten plastic is then injected into a mold. Once cooled, it takes the shape of the mold.

The versatility of injection molding is remarkable. It can create everything from components in smartphones to parts in medical devices. Each product requires careful design and planning. While the process is efficient, it can be costly for low-volume production. There are challenges in selecting the right material and ensuring mold durability. Mistakes in the design phase can lead to significant losses.

Despite its benefits, injection molding has its drawbacks. Not every product design is suitable for this method. Some items may need adjustments to make them mold-friendly. Additionally, environmental concerns arise from plastic waste. Manufacturers are exploring ways to use recycled materials. This shift could lead to more sustainable practices in the industry.

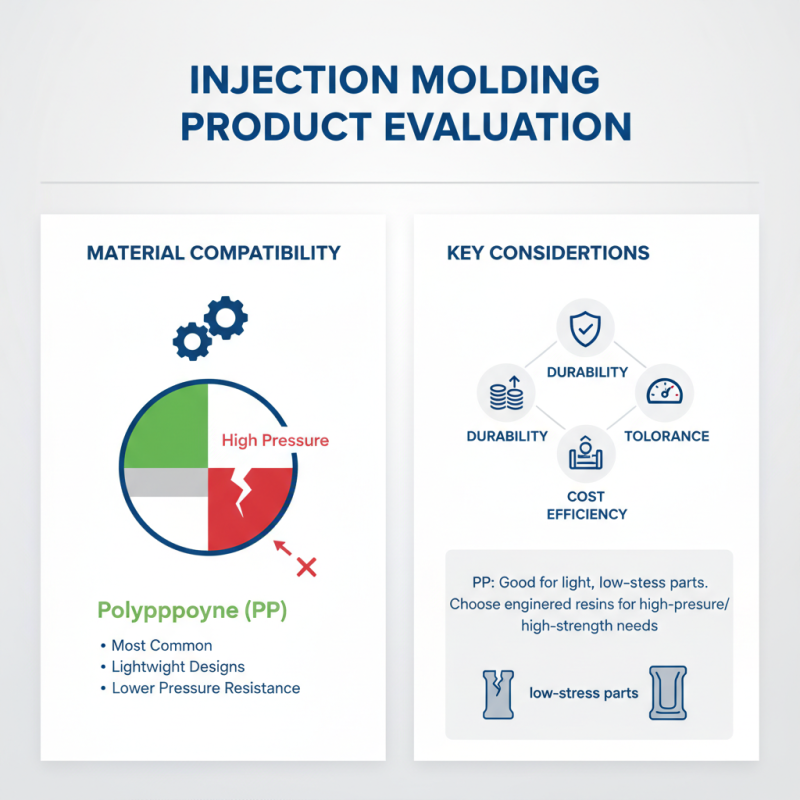

When evaluating injection molding products, several key factors come into play. One major factor is material compatibility. The choice of resin can significantly impact product durability and cost. According to industry reports, polypropylene is the most common material, ideal for lightweight designs. However, it may not always withstand high pressures, which can lead to failures.

Design versatility is another crucial aspect. Products must be able to fit diverse applications. Adequate design can reduce cycle times and enhance efficiency. For instance, complex geometries may require advanced molding techniques. Such techniques often demand higher initial investment and expertise. Balancing costs with design complexity is essential.

Sustainability is also gaining traction in the industry. A growing number of manufacturers are exploring biodegradable materials. Shifts toward eco-friendly products could reshape market dynamics. According to reports, about 30% of consumers prefer sustainable options. This preference signals a critical area for reflection. Brands must consider how well they align with evolving consumer values. Failing to do so might result in missed opportunities in a competitive market.

Injection molding is a vital process in modern manufacturing. Selecting the right materials is crucial for producing high-quality products. Various materials are used for injection molding, each offering unique properties and advantages.

Polypropylene is one of the most popular materials. It is lightweight, durable, and resistant to chemicals. According to industry reports, it accounts for about 30% of the injection molding market. Another common choice is Acrylonitrile Butadiene Styrene (ABS). It is known for its toughness and impact resistance. ABS is often used in automotive and consumer goods sectors.

However, not all materials are perfect. For instance, polycarbonate, while strong and heat-resistant, can be challenging to process due to its stringent temperature requirements. It can lead to design limitations. Understanding these nuances is vital for manufacturers aiming for efficiency and quality. Proper material selection can significantly affect production costs and product longevity.

Innovative injection molding technologies are revolutionizing various industries today. These advancements enhance efficiency and reduce production costs. For instance, the use of advanced materials like bio-based plastics is on the rise. A recent report shows that the global market for bioplastics is expected to reach $27 billion by 2025. This shift reflects growing environmental concerns, yet challenges remain in sourcing sustainable materials.

Moreover, 3D printing integration with injection molding is gaining traction. This allows for complex designs and rapid prototyping. According to Statista, the global 3D printing market is poised to exceed $40 billion by 2024. However, balancing speed and quality can be tricky for manufacturers. It often requires fine-tuning to achieve optimal results.

Technologies like multi-material molding are also emerging. This method combines different plastics into a single product, leading to enhanced functionality. Yet, the complexity of this process can raise costs. Achieving consistent quality across batches remains a potential hurdle for many. The future of injection molding appears promising, but it is not without its trials and tribulations.

| Product Type | Material Used | Applications | Innovative Features | Sustainability Aspect |

|---|---|---|---|---|

| Automotive Components | Polypropylene | Bumpers, Dashboards | Lightweight, High Impact Resistance | Recyclable Material |

| Consumer Electronics Housings | ABS Plastic | Phone Cases, Laptop Covers | High Gloss Finish, Sleek Design | Energy Efficient Production |

| Medical Devices | Polycarbonate | Syringes, Surgical Instruments | Autoclavable, Transparent | Biocompatible Materials |

| Packaging Solutions | HDPE | Bottles, Containers | Durable, Lightweight | Recyclable and Reused |

| Household Goods | Polyethylene | Toys, Storage Bins | Variety of Colors, Child Safe | Non-Toxic, Recyclable |

In the injection molding industry, innovation drives product development. Many leading brands focus on efficiency and sustainability. Advanced technologies are crucial. High-quality materials enhance durability while reducing costs. Recent reports indicate that the global injection molding market is projected to reach over $200 billion by 2025, reflecting a growing demand for precision-engineered products.

Several brands stand out with their unique offerings. Their top products include various components for the automotive, consumer electronics, and healthcare sectors. For instance, improved cooling systems in molds can increase cycle times significantly. However, not all adaptations yield positive returns. Some products fail to meet the anticipated performance due to design flaws. Continuous feedback loops from users can bridge these gaps, yet many companies overlook this crucial step.

Sustainability remains a pressing concern. Brands are exploring recyclable materials, yet the uptake is slow. Innovative practices like closed-loop processes show potential. Data suggests that only 30% of companies are implementing such measures effectively. The challenge persists in balancing production efficiency with environmental responsibilities. As the industry evolves, it must prioritize both quality and sustainability to keep pace with market expectations.