In the rapidly evolving world of manufacturing, choosing the right injection molding mold is critical. According to a recent report by the Association for Manufacturing Technology, the demand for advanced injection molding solutions is projected to grow by 4.7% annually until 2026. This data underscores the importance of selecting the best options. Industry expert Dr. Emily Chen states, "The right mold can significantly enhance production efficiency and product quality."

Mold design and material selection are paramount in the injection molding process. However, many manufacturers overlook these crucial elements, leading to inefficiencies. For instance, improper mold cooling can extend cycle times. This impacts overall productivity. Additionally, advanced technologies such as 3D printing are changing the landscape, offering new methods for mold creation.

As the industry progresses, reflection is necessary. Are traditional molds meeting current manufacturing needs? Or is it time to explore emerging technologies? Clearly, the choice of injection molding mold is not just a technical decision; it shapes the future of manufacturing processes. As the market continues to shift, staying informed and adaptable will be key to success.

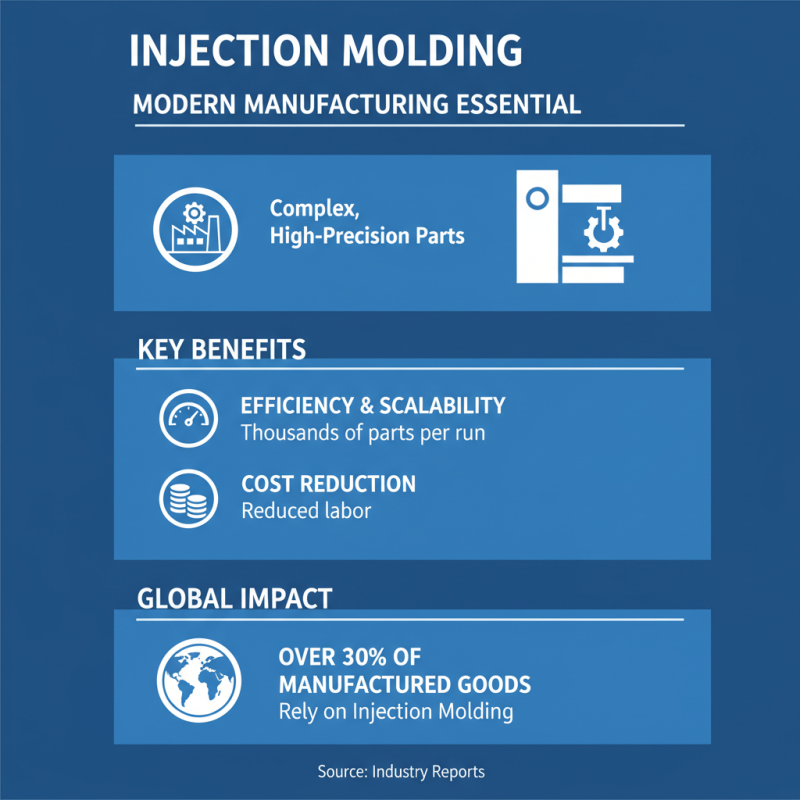

Injection molding is a vital process in modern manufacturing. It allows the production of complex parts with high precision. According to industry reports, over 30% of manufactured goods rely on injection molding. This method provides efficiency and scalability. Manufacturers can produce thousands of parts in a single run, reducing labor costs.

Quality control is crucial in injection molding. Even minor defects can lead to significant losses. The average cost of defects in production can reach up to $4.3 million annually for large manufacturers. It’s essential to choose the right molds to minimize risks. Investing in durable and efficient molds can offer long-term benefits. Yet, many companies struggle with mold selection, often overlooking critical factors like material compatibility and design intricacies.

The selection of injection molds requires careful consideration. Factors such as cooling time, part geometry, and material type play a significant role. One report indicated that 70% of injection molding failures stem from inadequate mold design. This highlights an ongoing challenge in the industry. Continuous improvement in mold technology is essential to meet evolving manufacturing needs. Companies must remain vigilant to avoid costly errors in their production lines.

Injection molding is crucial in manufacturing. Different types of molds cater to various needs. Understanding these molds can save time and costs.

There are two main types: single-cavity and multi-cavity molds. A single-cavity mold produces one part per cycle. It is simpler but slower for large production. Multi-cavity molds allow for multiple parts in one cycle. This boosts productivity but can be more complex to design.

Tip: Consider production volume before choosing a mold type. A lower volume might benefit from a single-cavity mold. Higher demand usually warrants a multi-cavity mold. Think about the design intricacies too. Complexity can lead to higher initial costs, but it might enhance efficiency in the long run.

Another option is family molds, which produce different parts simultaneously. They increase versatility but can complicate the process. Balancing the variety and efficiency is key. Evaluate project needs carefully. A smaller factory might struggle with the complexities of family molds.

Investing time in mold selection pays off. Mistakes in this phase can lead to delays and extra expenses. Be cautious, and always consult with experts if uncertain about mold choices.

| Mold Type | Material | Applications | Lifespan (Cycles) | Cost Range |

|---|---|---|---|---|

| Cold Runner Mold | Aluminum | Consumer Products | 100,000 - 500,000 | $5,000 - $15,000 |

| Hot Runner Mold | Steel | Automotive Parts | 500,000 - 1,000,000 | $20,000 - $50,000 |

| Stack Mold | Tool Steel | Electronic Housings | 1,000,000 - 3,000,000 | $30,000 - $80,000 |

| Multi-Cavity Mold | Bimetallic | Medical Devices | 300,000 - 1,000,000 | $15,000 - $40,000 |

| Prototype Mold | ABS Plastic | Testing Samples | 1,000 - 10,000 | $1,000 - $5,000 |

Choosing the right injection molding mold is crucial for your manufacturing success. This decision significantly impacts production efficiency and product quality. Industry reports indicate that about 60% of manufacturers struggle with mold selection. It's essential to focus on specific factors, including mold material, design complexity, and production volume.

Mold material plays a pivotal role in durability. Steel molds are robust and ideal for high-volume production, while aluminum molds are lighter and suitable for prototyping. The lifetime of a steel mold can exceed 1 million cycles, according to recent market analyses. However, cost is a consideration; steel molds can be up to 40% more expensive than aluminum options.

Design complexity can also affect the mold choice. Intricate designs may require more sophisticated molds, increasing lead times and costs. The average lead time for complex molds can be six weeks or longer, which may not align with tight production schedules. Understanding these dynamics is vital, as any misstep can lead to production delays and wasted resources.

When selecting injection molding molds for 2026, manufacturers face numerous choices. Understanding these options can help streamline production and improve efficiency. The right mold not only shapes the product but also impacts the overall manufacturing process. It’s vital to evaluate various factors, such as material compatibility and production volume.

Consider the type of material you plan to use. Different molds work best with specific plastics. Some molds may not be suitable for high-temperature materials. Always request samples if possible. This can prevent costly mistakes later. Think about the durability of the mold too. A well-made mold can last through numerous production cycles, saving time and resources.

Another key point is the mold's complexity. Simple designs can lower the initial cost, but intricate molds may enhance detail and precision. However, complexity often leads to higher maintenance needs. Be prepared for additional upkeep and potential troubleshooting. Balancing cost with quality is essential. The goal is to find what aligns best with your production needs.

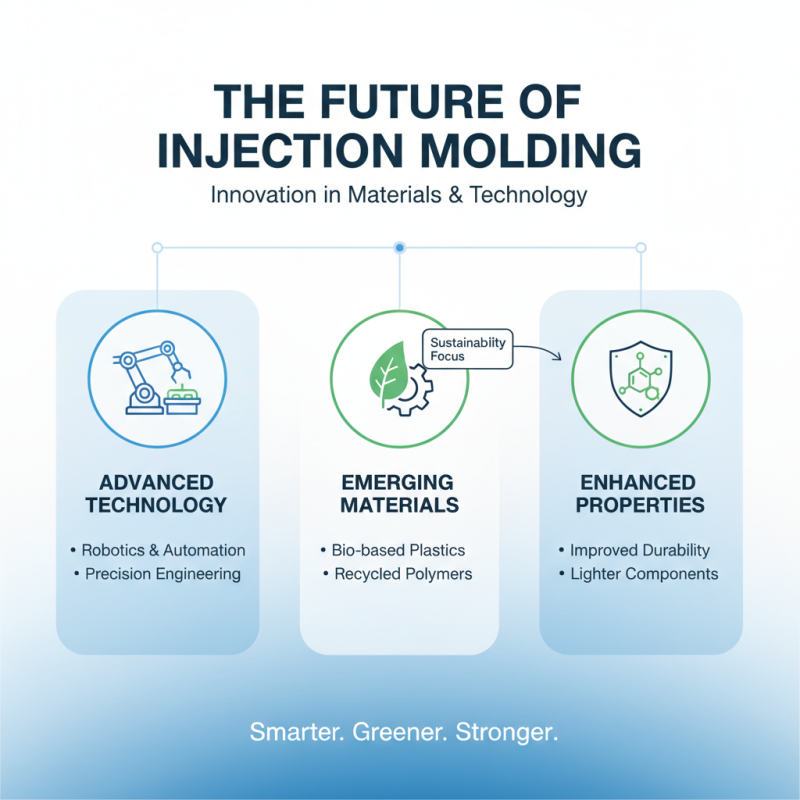

The future of injection molding technology is promising, showcasing significant advancements. Emerging materials are crucial for enhancing durability and sustainability. For instance, bio-based plastics are gaining traction. They help reduce environmental impact while maintaining quality.

Another trend involves the integration of automation. Smart systems can optimize production processes, improving efficiency. However, some manufacturers face challenges in adapting to these new technologies. Training staff becomes essential, yet often overlooked. Adjustments in workflow may also lead to short-term disruptions.

Additionally, additive manufacturing is blurring the lines between traditional injection molding and 3D printing. Combining these methods can produce complex geometries with lower material waste. Yet, scalability can be an issue. Many companies find scaling up production to be daunting. It raises questions about the long-term viability of such approaches. The industry must continuously reflect on these evolving dynamics to stay competitive.