As the electronics industry continues to evolve, manufacturers face increasing demands for efficient and reliable packaging solutions.

Low pressure molding systems have emerged as a transformative alternative in this landscape, providing numerous advantages over traditional methods. According to a recent report by MarketsandMarkets, the global market for low pressure molding technology is projected to reach $1.1 billion by 2025, driven by its unique ability to enhance product durability while minimizing thermal stress on sensitive electronic components. These systems utilize lower temperatures during the molding process, significantly reducing the risk of damaging delicate parts, while also allowing for tighter integration of components within compact spaces.

Moreover, with the growing emphasis on sustainability, low pressure molding technology aligns with environmentally friendly practices by reducing material waste and energy consumption.

This article explores how adopting low pressure molding systems can reshape electronics packaging solutions, leading to better performance, cost-effectiveness, and a shorter time-to-market.

Low pressure molding systems have emerged as a transformative alternative in this landscape, providing numerous advantages over traditional methods. According to a recent report by MarketsandMarkets, the global market for low pressure molding technology is projected to reach $1.1 billion by 2025, driven by its unique ability to enhance product durability while minimizing thermal stress on sensitive electronic components. These systems utilize lower temperatures during the molding process, significantly reducing the risk of damaging delicate parts, while also allowing for tighter integration of components within compact spaces.

Moreover, with the growing emphasis on sustainability, low pressure molding technology aligns with environmentally friendly practices by reducing material waste and energy consumption.

This article explores how adopting low pressure molding systems can reshape electronics packaging solutions, leading to better performance, cost-effectiveness, and a shorter time-to-market.

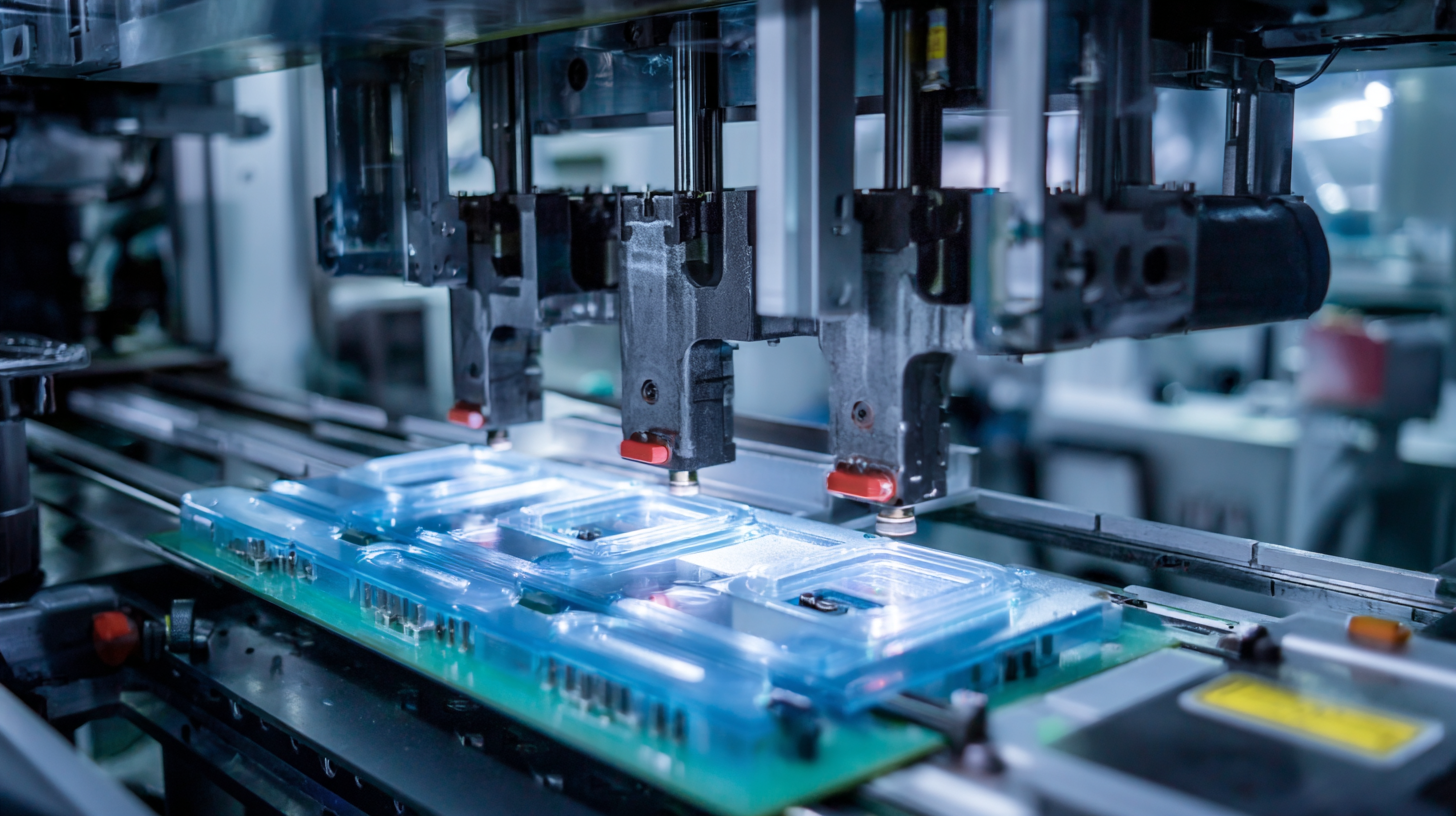

Low pressure molding systems have emerged as a revolutionary solution for electronics packaging, offering a myriad of advantages that enhance product durability and reliability. By employing a gentle molding process, these systems effectively encapsulate sensitive electronic components without the thermal stress typically associated with high-pressure methods. This is particularly crucial for delicate components prone to warping or damage, making low pressure molding an ideal choice in the electronics industry.

Tips: When selecting a low pressure molding system, consider the material compatibility with your electronic components. Ensure the chosen molding resin can withstand the lifecycle requirements of your products. Additionally, evaluate the design flexibility these systems offer, as they can easily accommodate intricate geometries that enhance component protection.

Furthermore, the use of low pressure molding technology significantly reduces production times and energy consumption. This efficiency not only lowers operational costs but also contributes to a more sustainable manufacturing process. As demand for advanced electronics continues to rise, integrating low pressure molding into your packaging solutions can yield substantial competitive advantages.

Tips: Keep an eye on the evolving market trends in low pressure molding technologies. Staying informed about innovations can help you maintain a lead in packaging performance and quality. Regularly reevaluating your process can also uncover opportunities for further optimization.

Low pressure molding systems have emerged as a transformative solution in electronics packaging, offering several key advantages for protecting sensitive components. One of the primary benefits is the reduction of thermal stress during the molding process. Traditional molding methods often involve high temperatures that can damage electronics; however, low pressure molding utilizes a gentle heating approach that preserves the integrity of delicate parts. This ensures that components remain fully operational, extending their lifespan and reliability.

Moreover, low pressure molding provides excellent environmental protection against moisture, chemicals, and mechanical stress. The materials used are often thermoplastic polymers that create a robust barrier, shielding electronic devices from potential damage. This is particularly important in demanding applications, such as automotive or medical devices, where reliability is paramount.

Tips: When considering low pressure molding for your electronics, evaluate the specific environmental conditions your devices will face. Additionally, ensure that the chosen molding material is compatible with the electronic components to maximize protection and performance. Regular testing can also help confirm the effectiveness of the protective mold over time, ensuring continued reliability in real-world applications.

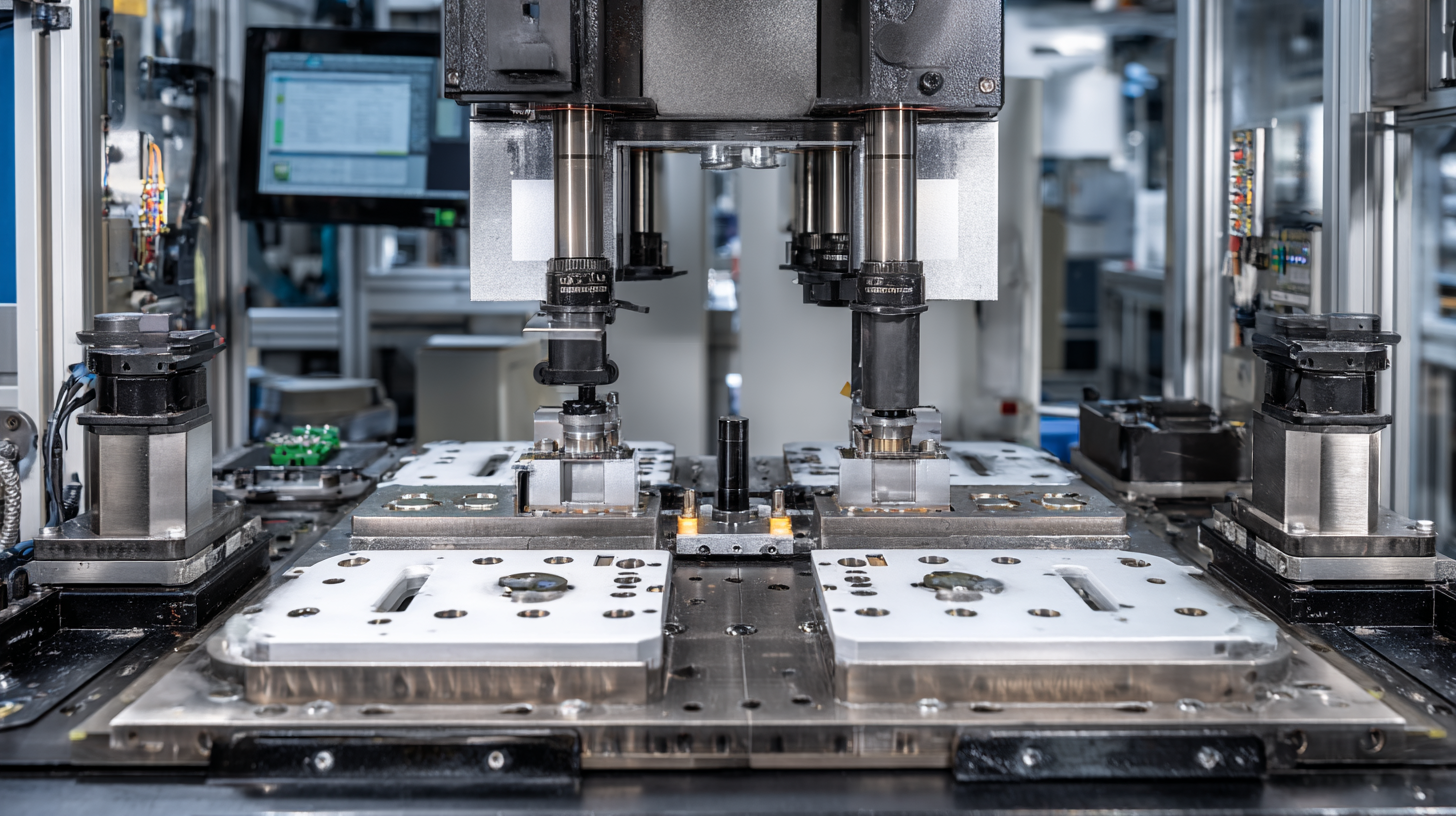

Low pressure molding systems have emerged as a game changer in electronics packaging solutions, primarily due to their ability to provide robust protection while minimizing thermal stress on delicate components. In contrast to traditional encapsulation methods that often rely on higher pressures, low pressure molding offers significant advantages in terms of safety and efficiency. This approach not only reduces the risk of damage to sensitive electronic parts but also allows for faster production cycles, ultimately enhancing overall operational productivity.

Low pressure molding systems have emerged as a game changer in electronics packaging solutions, primarily due to their ability to provide robust protection while minimizing thermal stress on delicate components. In contrast to traditional encapsulation methods that often rely on higher pressures, low pressure molding offers significant advantages in terms of safety and efficiency. This approach not only reduces the risk of damage to sensitive electronic parts but also allows for faster production cycles, ultimately enhancing overall operational productivity.

Tips: When considering low pressure molding, it’s essential to evaluate the type of materials used. Selecting the right thermoplastic materials can greatly influence the performance and cost-effectiveness of the molded component.

Moreover, low pressure molding systems often boast lower energy consumption than traditional methods. This eco-friendliness aligns with the increasing industry push towards sustainable manufacturing practices. The simplification of mold designs in low pressure systems also contributes to lower tooling costs, making this method an attractive option for businesses looking to optimize their production processes.

Tips: Ensure that your production team undergoes proper training on low pressure molding systems to maximize their efficiency and reduce operational errors.

Low pressure molding systems are becoming increasingly vital in the electronics industry due to their versatility and effectiveness in packaging solutions. These systems utilize thermoplastic materials that cure at lower temperatures, which significantly reduces the risk of thermal damage to sensitive electronic components. According to the Markets and Markets report, the global low pressure molding market is expected to grow from USD 1.3 billion in 2021 to USD 2.1 billion by 2026, reflecting a compound annual growth rate (CAGR) of 9.8%. This growth is driven by the rising demand for reliable protection in applications such as automotive electronics, consumer electronics, and industrial automation.

The applications of low pressure molding in today’s electronics industry are manifold. For instance, this technology is widely adopted in encapsulating circuit boards, connectors, and various electronic devices, providing robust insulation against moisture, dust, and mechanical shocks. A study from Research and Markets indicates that the automotive sector alone is projected to account for over 40% of the low pressure molding market share by 2025, underscoring the importance of this technology in safeguarding critical automotive electronics. Furthermore, with the continuous evolution of smart devices and Internet of Things (IoT) products, the demand for efficient and effective packaging solutions, such as low pressure molding, will only accelerate, marking a significant trend in electronic manufacturing.

Low pressure molding systems have become increasingly popular in the electronics packaging industry, offering several advantages over traditional methods. Implementing these systems effectively in production processes requires adherence to best practices that ensure quality, efficiency, and cost-effectiveness. One essential tip for success is to conduct thorough material compatibility assessments. Selecting the right molding compounds that are compatible with the electronic components can significantly enhance protection and performance.

Another best practice is to optimize the molding process parameters such as temperature, pressure, and cycle time. Fine-tuning these variables not only contributes to superior mold filling but also minimizes defects. It’s advisable to carry out trial runs and adjust parameters based on the specific requirements of the project. Additionally, training personnel on low pressure molding techniques can lead to improved outcomes. Knowledgeable staff can troubleshoot potential issues quickly, ensuring the production line runs smoothly.

Lastly, investing in proper tooling and equipment is crucial for achieving high-quality results. Robust molds that can withstand repeated cycles will enhance the longevity of the production process. Regular maintenance and inspections of the molding systems can also prevent downtime and extend equipment life. By following these best practices, manufacturers can effectively integrate low pressure molding into their operations, realizing its full potential in electronics packaging solutions.