In the rapidly evolving landscape of manufacturing, achieving excellence in injection molding techniques has become crucial for businesses striving for superior production results. According to a report by MarketsandMarkets, the global injection molding market is projected to grow from USD 210.64 billion in 2021 to USD 319.52 billion by 2026, reflecting a compound annual growth rate (CAGR) of 8.67%. This growth underscores the increasing reliance on injection molding as a cornerstone for high-volume production in various sectors, including automotive, consumer goods, and medical devices. To navigate this competitive terrain, professionals must adopt the best injection molding practices that optimize efficiency and enhance product quality. This blog will explore the essential techniques and strategies that can elevate your injection molding processes, positioning your organization at the forefront of superior manufacturing outcomes.

Achieving success in the injection molding industry requires a comprehensive understanding of import and export certifications, particularly for markets like Korea, which has undergone significant economic transformation. With its rapid growth from the 1980s onward and the subsequent democratization, Korea has emerged as a key player in global manufacturing. Companies looking to penetrate this market must navigate a complex landscape of regulations that govern product standards and safety.

Certifications are not merely bureaucratic hurdles; they are essential for ensuring that products meet the rigorous quality expectations of Korean consumers. Understanding these certifications can be a differentiator for injection molding businesses aiming for excellence. By obtaining the appropriate certifications, companies can enhance their credibility and streamline their entry into the market. This focus on compliance not only facilitates smoother export processes but also aligns with best practices in production techniques, ultimately leading to superior outcomes in injection molding projects.

This chart illustrates the performance of various injection molding techniques in terms of production efficiency and defect rates across different materials. The data demonstrates how specific techniques can influence overall production outcomes.

The advent of digital innovations in injection molding techniques is transforming the landscape of manufacturing, enhancing precision, efficiency, and quality. As global industries shift towards automation and digital technologies, the injection molding sector stands to benefit significantly from advancements such as artificial intelligence and IoT integration. These technologies empower manufacturers to optimize their production processes, reduce waste, and improve overall product quality. According to recent industry reports, companies investing in digital transformation can expect up to a 30% reduction in operational costs and a 50% increase in production efficiency.

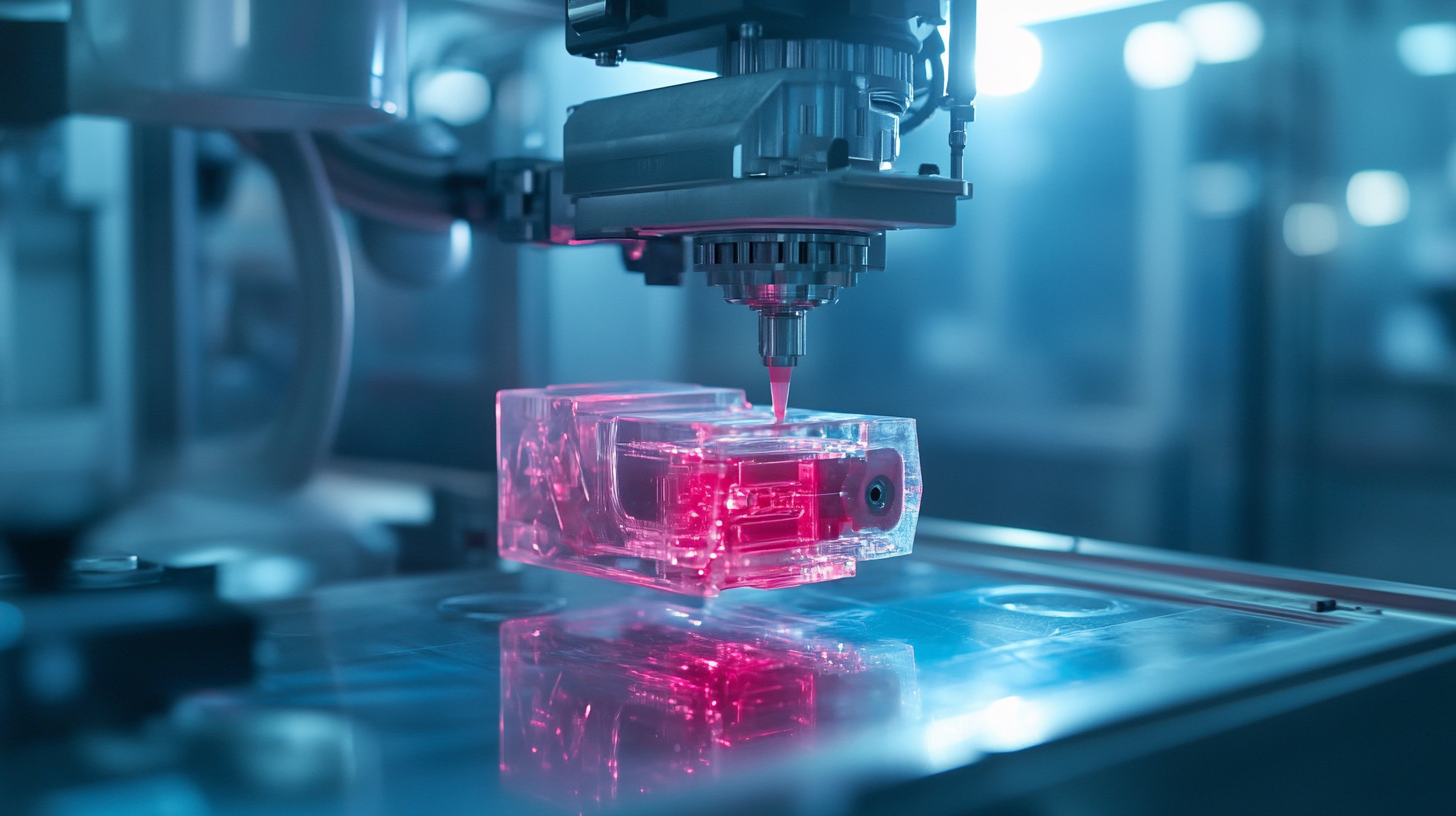

Moreover, the intersection of advanced materials and digital techniques paves the way for superior product outcomes. For instance, the emergence of bio-compatible materials in dental implant production illustrates how innovative materials coupled with precise engineering can create a new standard in manufacturing. Projections indicate that the market for zirconia dental implants will experience disruptive growth, driven by technological advancements and increasing consumer demand for high-quality dental solutions. By embracing these digital innovations, manufacturers can not only achieve excellence in injection molding but also ensure responsiveness to evolving market needs, solidifying their competitive edge in the industry.

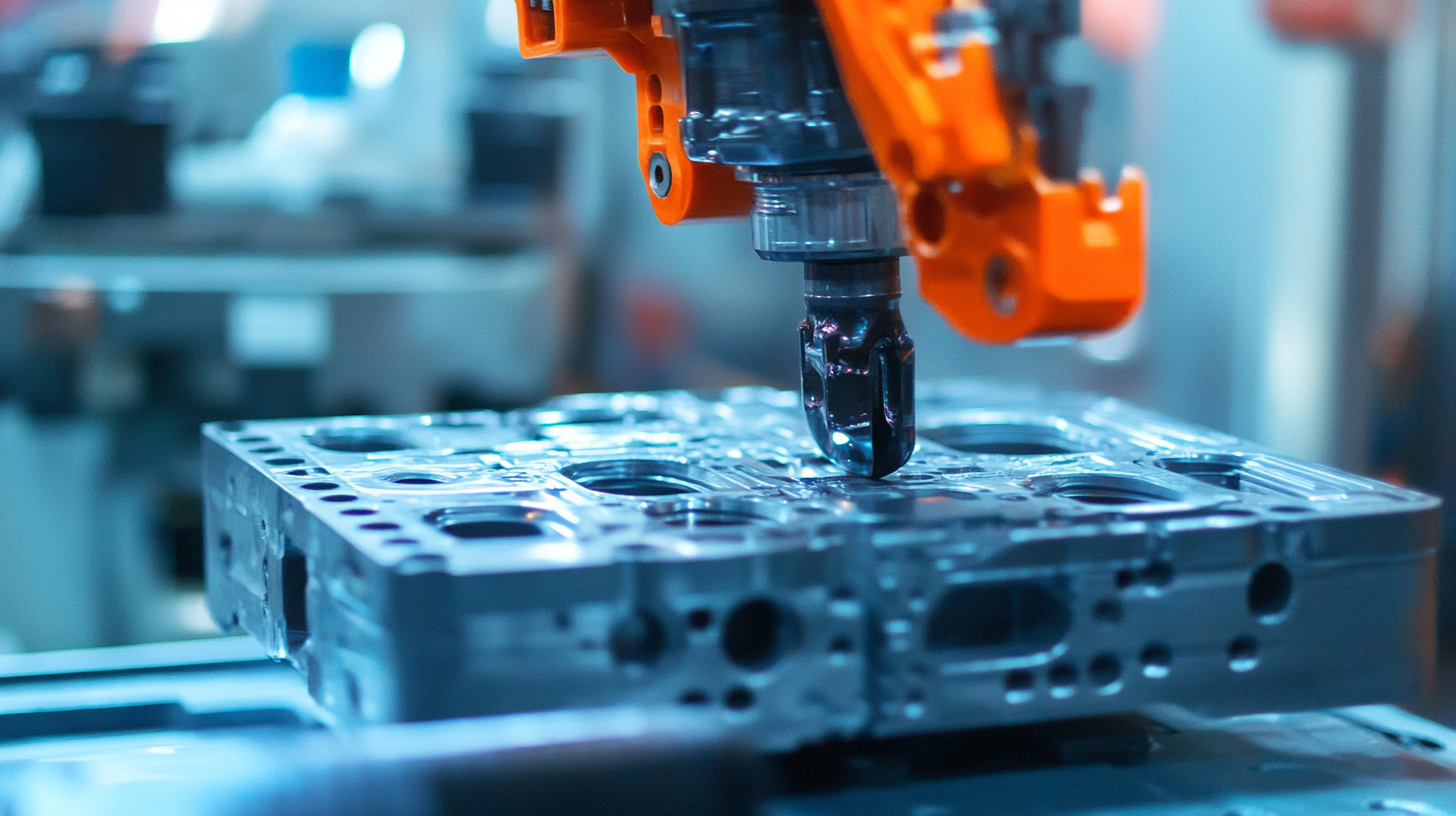

Achieving superior production efficiency in injection molding is paramount for businesses looking to enhance quality while reducing costs. The foundation of excellence in this field lies in understanding and implementing the best injection molding methods available. Techniques such as scientific molding, advanced process monitoring, and the use of hot runner systems contribute significantly to precision and consistency. Scientific molding, for instance, involves a heavily data-driven approach that optimizes each phase of production, ensuring the final product meets the highest quality standards.

Another critical aspect is the implementation of advanced materials and automation technologies. By utilizing innovative polymers and composites, manufacturers can achieve better performance characteristics and lower cycle times. Furthermore, integrating automation in the injection molding process allows for quicker adjustments and real-time quality control, enhancing overall production efficiency. Adopting these cutting-edge techniques not only streamlines the production process but also minimizes waste, ultimately leading to a more sustainable operation.

Achieving excellence in injection molding production requires a keen focus on quality control. Implementing best practices not only enhances the product quality but also streamlines the overall manufacturing process. Regularly calibrating your equipment is crucial to ensure consistent output and avoid defects. This prevents downtime and unnecessary rework, ultimately saving time and resources.

Another significant aspect of quality control is conducting thorough inspections at various stages of production. Utilizing advanced technologies such as automated vision systems can help in identifying defects early in the process. This proactive approach minimizes waste and reinforces the integrity of your product.

Additionally, fostering a culture of continuous improvement among the workforce can lead to innovative solutions that elevate production standards. Encourage team members to share feedback and participate in problem-solving initiatives. Regular training and workshops can help keep the team updated on the latest techniques and quality control measures, ensuring that everyone is aligned towards achieving superior results in injection molding production.

In today’s manufacturing landscape, leveraging advanced technology in injection molding processes is essential for achieving excellence. The integration of automation, data analytics, and innovative materials plays a crucial role in optimizing production efficiency and enhancing product quality. By utilizing real-time monitoring systems, manufacturers can track the molding conditions and promptly adjust settings to minimize defects and waste.

**Tip:** Invest in automated systems that utilize sensors and feedback loops. This allows for continuous data collection which can help in identifying performance bottlenecks and optimizing cycle times.

Moreover, employing simulation software during the design phase can predict potential issues before the production begins, such as flow discrepancies and cooling inefficiencies. This proactive approach saves both time and resources in the long run.

**Tip:** Utilize 3D simulation tools to visualize the injection molding process. This aids in making informed adjustments to designs, ensuring that the final product meets specifications without extensive rework.

By embracing these technological advancements, manufacturers can refine their injection molding techniques, ensuring superior results and maintaining a competitive edge in the market.

| Technique | Benefits | Technology Used | Production Rate (units/hour) | Common Materials |

|---|---|---|---|---|

| Hot Runner Systems | Reduced waste, improved cycle times | Electronic Temperature Control | 200 | ABS, Polycarbonate |

| Multi-Cavity Molding | Increased output, lower costs per unit | Advanced CAD Software | 150 | Polypropylene, Nylon |

| Gas-Assisted Injection Molding | Reduced part weight, improved material flow | Pressure Sensors | 120 | PVC, PS |

| Injection Blow Molding | Complex shapes, high precision | Robotics | 100 | PET, HDPE |

| Rapid Prototyping | Faster design iterations, lower costs | 3D Printing Technology | 80 | PLA, ABS |