As we approach 2025, the landscape of product molding is set to undergo significant transformations, shaped by advancements in technology and evolving market demands. According to a recent report by MarketsandMarkets, the global market for product molding is projected to reach $259.9 billion by 2025, at a compound annual growth rate (CAGR) of 4.2%. This growth highlights the increasing reliance of various industries on innovative molding techniques to enhance product functionality while reducing production costs.

In this context, several key trends are emerging that are poised to redefine the product molding process. The integration of automation and smart manufacturing practices stands out as a critical driver of efficiency and precision. Additionally, a growing emphasis on sustainability is pushing manufacturers to explore eco-friendly materials and processes, aligning with consumer expectations and regulatory policies. As highlighted in the 2023 Global Plastics Report, nearly 70% of industry leaders are prioritizing the adoption of sustainable methods in their product molding operations.

This article delves into the top trends in product molding for 2025, providing insights into how businesses can leverage these changes to remain competitive in an increasingly dynamic marketplace. Understanding these trends will be vital for stakeholders aiming to innovate and thrive in the rapidly evolving field of product molding.

As we look towards 2025, the landscape of product molding is set to be transformed by several emerging technologies. One of the most impactful innovations is the adoption of advanced automation and robotics. According to a report from Deloitte, implementing robotics in manufacturing can increase productivity by up to 30% while reducing operational costs by nearly 20%. This trend indicates a shift towards more precision and efficiency in the molding process, enabling manufacturers to meet the growing demand for high-quality, customized products.

Another significant development is the integration of artificial intelligence (AI) and machine learning in product design and production. A study by McKinsey highlights that the use of AI in manufacturing can lead to a 50% reduction in design cycles and a 15% increase in productivity. These technologies are poised to optimize the molding process, allowing for rapid prototyping and reducing waste, which is particularly crucial in an industry increasingly focused on sustainability and minimizing ecological footprints. These trends will not only enhance production capabilities but also encourage a dynamic shift towards smarter, more sustainable manufacturing practices.

| Trend | Description | Expected Impact | Technologies Involved |

|---|---|---|---|

| 3D Printing | Increasing use of additive manufacturing for rapid prototyping and production. | Faster production times and lower costs for small batches. | Polymer Jetting, FDM, SLS |

| Smart Molding Solutions | Integration of IoT in molding processes for real-time monitoring. | Improved efficiency and reduced waste. | AI, Sensors, Cloud Computing |

| Sustainable Materials | Shift towards biodegradable and recyclable materials in molding. | Lower environmental impact and compliance with regulations. | Bioplastics, Recycled Polymers |

| Advanced Mold Design | Incorporation of simulation software for mold design optimization. | Reduced design cycle time and improved product quality. | CAD Software, Simulation Tools |

| Micro Molding | Manufacturing small, intricate parts with high precision. | Expansion of applications in medical and electronics industries. | Ultra-precision Machines, Advanced Materials |

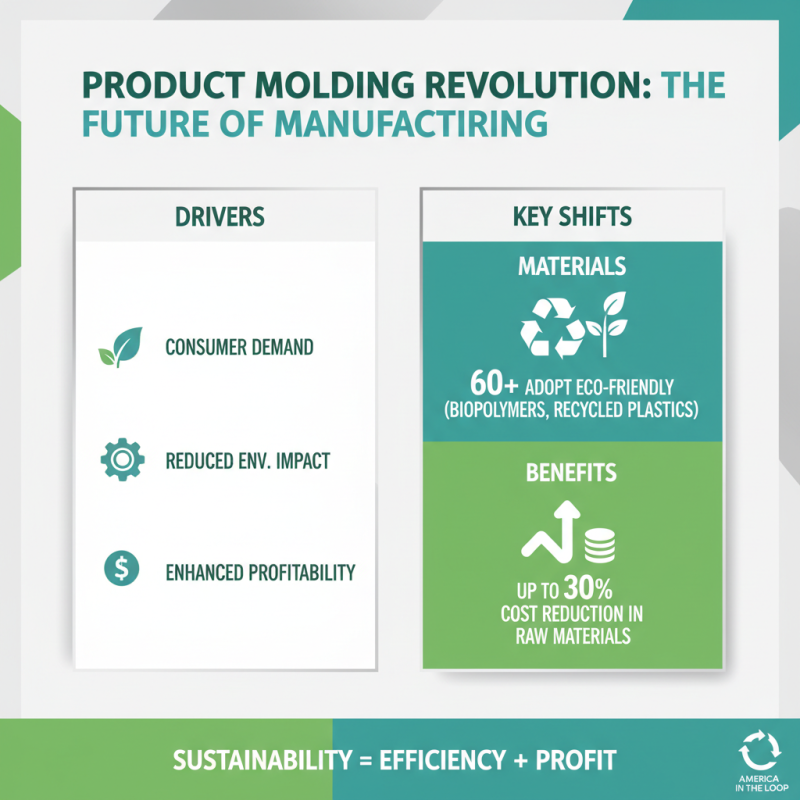

As we move towards 2025, sustainable practices are set to significantly transform product molding processes across various industries. According to a report by the American Society of Plastics Engineers, over 60% of manufacturers are now adopting eco-friendly materials and processes to meet consumer demand for sustainability. This shift is not just about reducing environmental impact, but also about enhancing operational efficiency. Implementing sustainable practices, such as using biodegradable polymers and recycled materials, can reduce raw material costs by up to 30%, thus driving profitability.

Moreover, innovations in molding technologies are contributing to the increased sustainability of operations. For instance, advancements in injection molding techniques allow for the use of less energy and water, with reports indicating a reduction of energy consumption by approximately 40% in modern systems. As more companies strive to comply with stringent environmental regulations, adopting these technologies will be a key factor in staying competitive. The integration of sustainability into the product molding process is no longer an option but a necessity, setting the stage for a greener and more efficient manufacturing landscape by 2025.

The future of product molding is being revolutionized by innovative materials that enhance performance and reduce environmental impact. According to a recent report by Smithers Pira, the global market for advanced plastics in product molding is projected to grow by 5.1% annually, reaching $85 billion by 2025. This growth is largely driven by the adoption of sustainable materials, such as bioplastics, which have gained traction due to both consumer demand and regulatory pressures. These materials not only offer similar mechanical properties to traditional plastics but also significantly lower the carbon footprint associated with product manufacturing.

As manufacturers look to the future, it’s crucial to stay ahead of the curve by exploring cutting-edge materials like thermoplastic elastomers (TPEs) and bio-based polymers. TPEs, for instance, provide flexibility and durability while being 100% recyclable, catering to the increasing demand for sustainable solutions. A recent survey from Deloitte highlights that 70% of consumers are willing to pay more for products made with sustainable materials.

Tip: When selecting materials for product molding, consider not just the functionality and cost, but also the environmental impact. Engaging with suppliers who offer green alternatives can enhance your brand's reputation and appeal to eco-conscious consumers. Investing in innovative materials not only aligns with global sustainability trends but also positions your products favorably in a competitive market.

The integration of automation and robotics in modern product molding techniques is transforming the industry, allowing manufacturers to enhance efficiency and precision. Recent advancements highlight a revamped robot line designed specifically for injection molding machines with increased clamping force. This innovation aims to support the growing demand for faster and more accurate production processes, particularly in sectors like medical device manufacturing where automation is critical for assembly and testing operations.

As companies shift towards more automated systems, we see the emergence of AI-driven technologies that further streamline processes. The implementation of artificial intelligence in injection molding machines enables real-time process assistance, improving not only productivity but also quality control. Furthermore, collaborative robots (cobots) are becoming integral in plastics manufacturing, working alongside human operators to optimize workflows and reduce error rates. These developments underscore a pivotal shift in how manufacturing operates, paving the way for a more efficient and sustainable future in product molding.

The product molding industry is poised for significant transformations by 2025, driven by a variety of market trends that influence strategic decisions among manufacturers. A notable trend is the ongoing diversification of client bases and market strategies, as illustrated by companies adapting to the increasing demand for consumer-grade products. For instance, reports indicate that the market for traditional bath bombs and silicone molds is expected to evolve substantially, with increasing sizes and design variations catering to both personal consumers and small businesses.

Another critical factor shaping product molding strategies is the robust growth projected in the automotive mold sector. The global automotive mold market is anticipated to reach a valuation of $3.62 billion by 2025 and further grow to $5.95 billion by 2034, reflecting a compound annual growth rate of 5.69%. This growth emphasizes the need for manufacturers to adopt innovative molding techniques and materials to stay competitive, especially in light of challenges such as escalating tariffs affecting pricing and competitiveness in international markets. As such, the industry will likely focus on digital transformation and enhanced collaboration, enabling businesses to capitalize on emerging opportunities and navigate market instabilities.