As we move toward 2025, the landscape of manufacturing technology is poised for significant transformation, with injection machines at the forefront of this evolution. These machines, integral to various industries ranging from automotive to consumer goods, are increasingly becoming more efficient and innovative. The demand for higher productivity, reduced waste, and enhanced precision is driving the development of new technologies, materials, and processes within the injection molding sphere.

One of the most notable trends is the integration of smart technology into injection machines, enabling real-time monitoring and data analytics to optimize performance. This shift not only reduces operational costs but also improves the overall quality of the products being manufactured. Additionally, advancements in energy efficiency are expected to lead to machines that consume less power while delivering superior output, addressing the growing concerns surrounding sustainability in manufacturing.

As we explore the top injection machine trends for 2025, it is essential to consider how these innovations will shape the future of production. The evolution of injection machines promises to enhance operational efficiency, reduce lead times, and ultimately, redefine the capabilities of manufacturers worldwide. Preparing for these changes will be crucial for businesses looking to maintain a competitive edge in an increasingly fast-paced and technology-driven market.

The emergence of smart technologies in injection molding machines is transforming the industry, enhancing productivity and precision. With data from recent industry reports indicating that the smart manufacturing market is projected to reach over $400 billion by 2025, injection molding stands at the forefront of this evolution.

The integration of IoT (Internet of Things) devices within these machines facilitates real-time monitoring, predictive maintenance, and data analytics, significantly reducing downtime and improving operational efficiencies.

Moreover, advanced automation, powered by artificial intelligence and machine learning, is revolutionizing the injection molding process. According to a study published by a leading industry research firm, companies that implement smart technologies can achieve up to a 20% reduction in energy consumption and a 25% improvement in cycle times.

This not only leads to cost savings but also aligns with the industry’s shift towards sustainable practices. As manufacturers adopt these innovations, the focus on smart technologies in injection molding machines will likely become a critical driver of competitiveness, enabling businesses to adapt swiftly to changing market demands and improve overall product quality.

The injection molding industry is experiencing a significant transformation driven by advancements in energy efficiency and sustainability practices. As manufacturers seek to reduce their carbon footprint, the adoption of energy-efficient machinery has become a priority. According to a recent report by the International Plastics Manufacturers Association, energy-efficient injection molding machines can reduce energy consumption by up to 60% compared to traditional models. This shift not only leads to lower operational costs but also aligns with global sustainability goals.

Furthermore, innovative materials and production processes are being developed to enhance the sustainability of injection molding operations. The introduction of bio-based and recycled materials is gaining traction, allowing manufacturers to produce high-quality products while minimizing environmental impact. A study conducted by the Association of Plastic Recyclers highlights that integrating recycled content into injection molded products can divert significant amounts of waste from landfills, improving overall sustainability. These practices not only contribute to a circular economy but also respond to the increasing consumer demand for eco-friendly products, marking a pivotal shift in the industry's approach to manufacturing.

The landscape of injection molding is evolving, driven significantly by innovative materials that enhance design and efficiency. As manufacturers seek to improve the performance and sustainability of their products, materials like bio-based resins, recycled plastics, and advanced polymers are gaining traction. These materials not only offer reduced environmental impact but also improve the mechanical properties of final products, allowing for more complex designs and lightweight structures.

Moreover, the integration of smart materials is shaping the future of injection machine design. Shape memory alloys and conductive polymers are paving the way for more responsive and adaptive manufacturing processes. These materials can react to temperature changes or external stimuli, enabling manufacturers to create multifunctional components that enhance product value and usability. The ongoing research into these innovative materials reflects a significant shift towards a more efficient and sustainable industry, promising exciting possibilities for the next wave of injection molding technology.

The integration of automation and robotics in manufacturing processes is set to revolutionize the injection molding industry by 2025. As companies strive for enhanced efficiency and productivity, the amalgamation of these advanced technologies will optimally streamline operations. Automated systems will not only reduce manual intervention but also increase precision and consistency in the production cycle. This technological shift enables manufacturers to operate at a faster pace while maintaining high-quality standards, ultimately leading to higher output rates and minimized wastage.

Furthermore, the incorporation of robotics will facilitate more complex and intricate designs that were previously unattainable with traditional methods. With the aid of artificial intelligence and machine learning, robots can adapt to various manufacturing demands seamlessly, ensuring that production lines remain flexible and responsive to market changes. This evolutionary approach not only enhances operational efficiencies but also fosters innovation in product design and development. As manufacturers embrace these trends, the injection molding sector is poised for unprecedented growth and transformation, making automation and robotics indispensable components of future production strategies.

This chart illustrates the projected growth in the integration of automation and robotics in injection molding processes from 2023 to 2025, highlighting key trends that indicate improvements in innovation and efficiency.

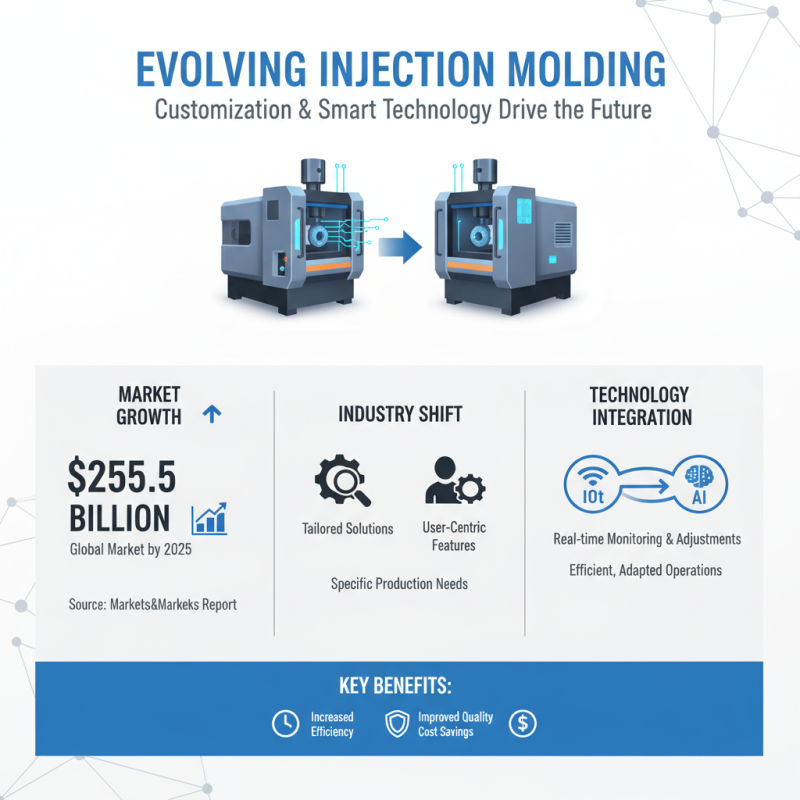

As the injection molding industry evolves, the emphasis on customization and user-centric features is becoming increasingly prominent. According to a report by MarketsandMarkets, the global injection molding market is expected to reach $255.5 billion by 2025, highlighting the industry's shift towards more tailored solutions. Customers are now seeking machines that can adapt to their specific production needs, which has led to the integration of advanced technologies such as IoT and AI into machine designs. These innovations not only enhance production processes but also allow for real-time monitoring and adjustments, ensuring efficient operations tailored to individual requirements.

User-centric machine features have become essential as manufacturers aim to improve operator experience and productivity. A survey conducted by the Association for Manufacturing Technology (AMT) revealed that 68% of manufacturers prioritize user-friendly interfaces and ergonomics in their purchasing decisions. Programmable controls and customizable interfaces are now standard, enabling operators to streamline workflows and reduce training time. Additionally, the rise of collaborative robots (cobots) in the injection molding sector further emphasizes the move toward machines that complement human capabilities, allowing for a safer and more efficient working environment. The focus on these trends indicates a future where customization and user-centric design not only drive innovation but also significantly enhance operational efficiency in the injection molding industry.